BladeMaintenance

CheckingforaBentBlade

Afterstrikingaforeignobject,inspectthemachinefor

damageandmakerepairsbeforerestartingandoperating

theequipment.Torqueallthespindlepulleynutsto130

to150ft-lb(176to203N⋅m).

1.Positionthemachineonalevelsurface.Raisethe

cuttingunit,engagetheparkingbrake,putthe

tractionpedalinneutral,makesurethePTOswitch

isintheOffposition,stoptheengine,andremove

theignitionkey.Blockthecuttingunittopreventit

fromaccidentallyfalling.

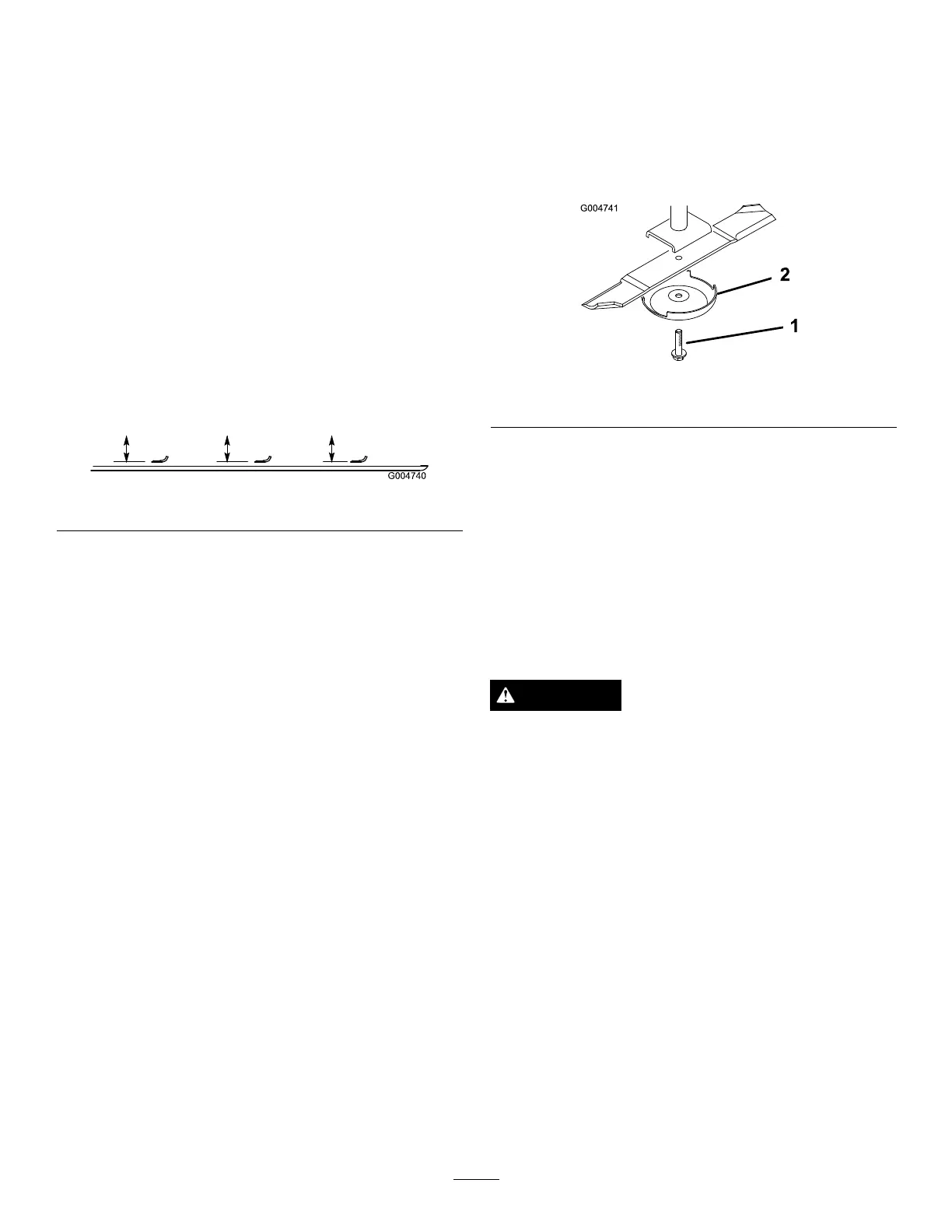

2.Rotatethebladeuntiltheendsfaceforwardand

backward(Figure99).Measurefromtheinsideof

thecuttingunittothecuttingedgeatthefrontof

theblade.Recordthisdimension.

Figure99

3.Rotatetheoppositeendofthebladeforward.

Measurebetweenthecuttingunitandcuttingedge

ofthebladeatthesamepositionasinstep2.The

differencebetweenthedimensionsobtainedinsteps

2and3mustnotexceed1/8inch(3mm).Ifthe

dimensionexceeds1/8inch(3mm),thebladeis

bentandmustbereplaced;refertoRemovingand

InstallingtheCutterBlade.

RemovingandInstallingthe

CutterBlade(s)

Theblademustbereplacedifasolidobjectishit,the

bladeisoutofbalance,orifthebladeisbent.Always

usegenuineTororeplacementbladestobesureofsafety

andoptimumperformance.Neverusereplacement

bladesmadebyothermanufacturersbecausetheycould

bedangerous.

1.Raisethecuttingunittothehighestposition,engage

theparkingbrake,stoptheengine,andremovethe

ignitionkey.Blockthecuttingunittopreventitfrom

accidentallyfalling.

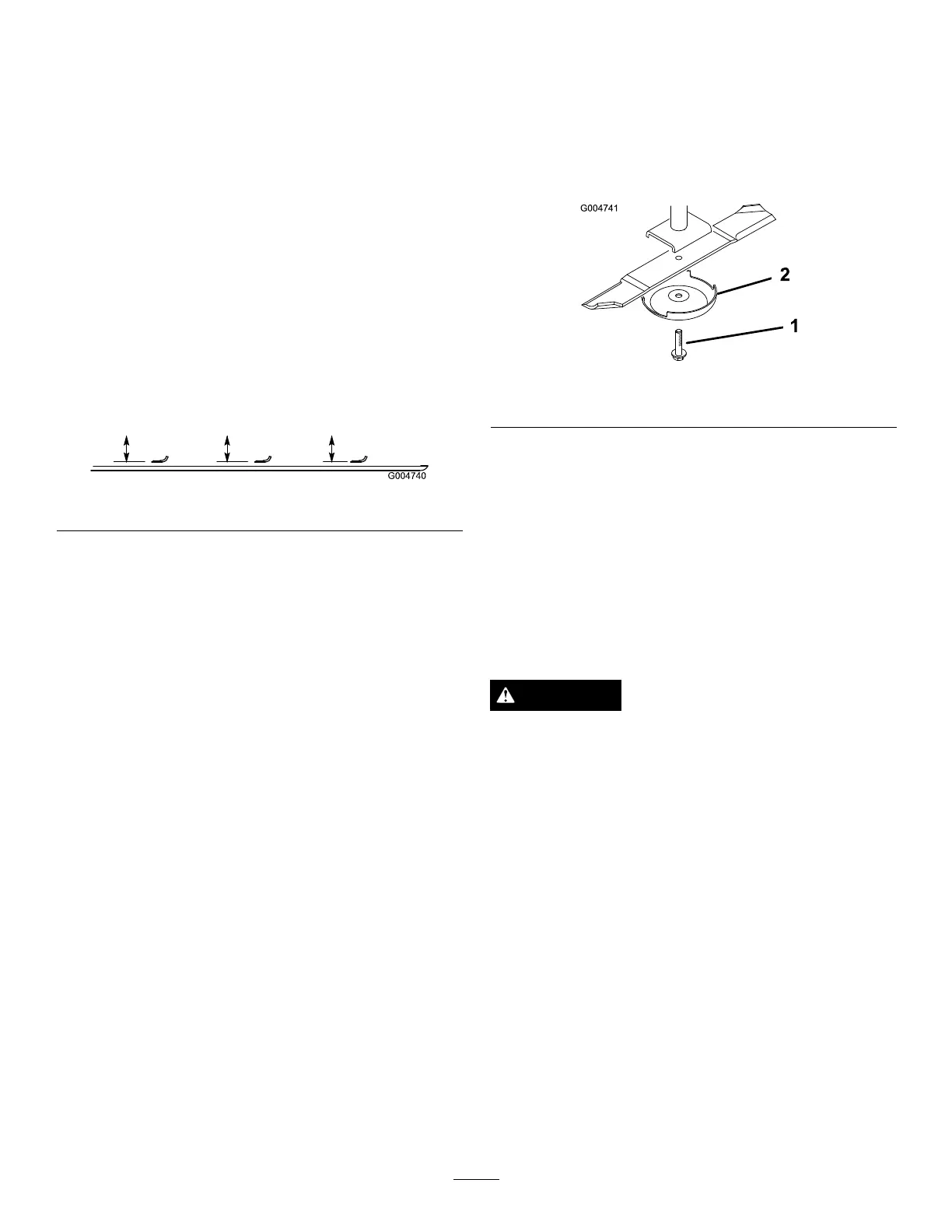

2.Grasptheendofthebladeusingaragorthickly

paddedglove.Removethebladebolt,anti-scalpcup,

andbladefromthespindleshaft(

Figure100).

3.Installtheblade,anti-scalpcup,andbladebolt.

Tightenthebladeboltto85to110ft-lb(115to149

N⋅m).

Important:Thecurvedpartoftheblademust

bepointingtowardtheinsideofthecuttingunit

toensurepropercutting.

Note:Afterstrikingaforeignobject,torqueallthe

spindlepulleynutsto130to150ft-lb(176to203

N⋅m)andthebladeboltsto85to110ft-lb(115to

149N⋅m).

Figure100

1.Bladebolt2.Anti-scalpcup

InspectingandSharpeningthe

CutterBlade(s)

ServiceInterval:Aftertherst10hours—Checkblade

bolttorque

Every50hours—Checkbladebolt

torque

Beforeeachuseordaily—Check

mowerbladecondition

DANGER

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator’s

orbystander’sarea,resultinginseriouspersonal

injuryordeath.Tryingtorepairadamagedblade

mayresultindiscontinuedsafetycerticationof

theproduct.

•Inspectthebladeperiodicallyforwearor

damage.

•Nevertrytostraightenabladethatisbentor

weldabrokenorcrackedblade.

•Replaceawornordamagedblade.

Twoareasmustbeconsideredwhencheckingand

servicingthecutterblade-thesailandthecuttingedge.

Bothcuttingedgesandthesail,whichistheturned

upportionoppositethecuttingedge,contributetoa

goodquality-of-cut.Thesailisimportantbecauseit

liftsthegrassupstraight,therebyproducinganeven

cut.However,thesailwillgraduallyweardownduring

operation,andthisconditionisnormal.Asthesail

65

Loading...

Loading...