6.Adjusttheothersetofnutstoraiseorlowertherear

ofthecuttingunitandattainthecorrectcuttingunit

pitch.

7.Tightenthejamnuts.

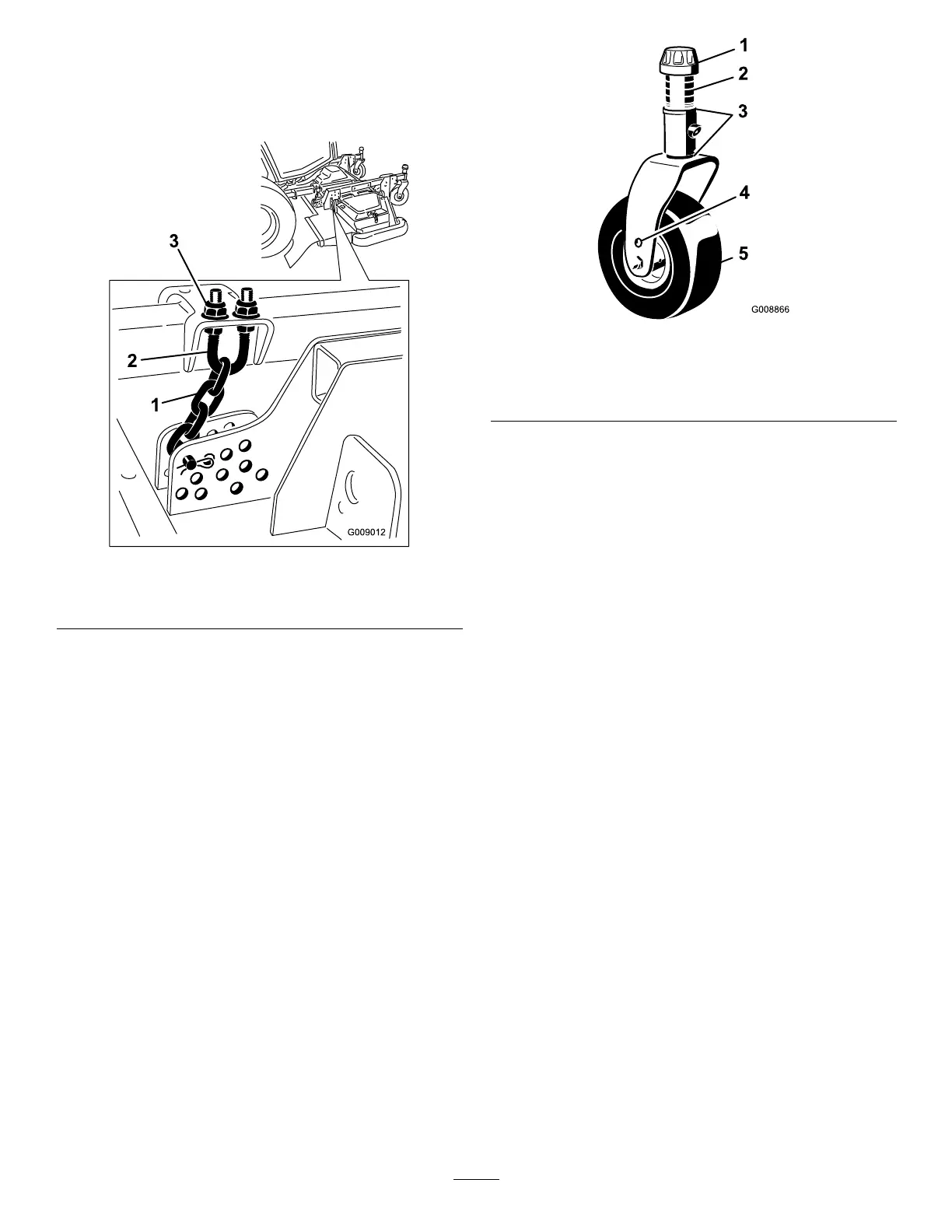

Figure95

1.Height-of-cutchain3.Nut(2)

2.U-bolt

AdjustingtheSideCuttingUnits

1.Removethetensioningcapfromthecastorspindle

shaftandslidethespindleoutofthecastorarm

(

Figure96).Repositiontheshims,asrequired,to

raiseorlowerthecastorwheeluntilthecuttingunit

hasthecorrectpitch.

2.Installthetensioningcap.

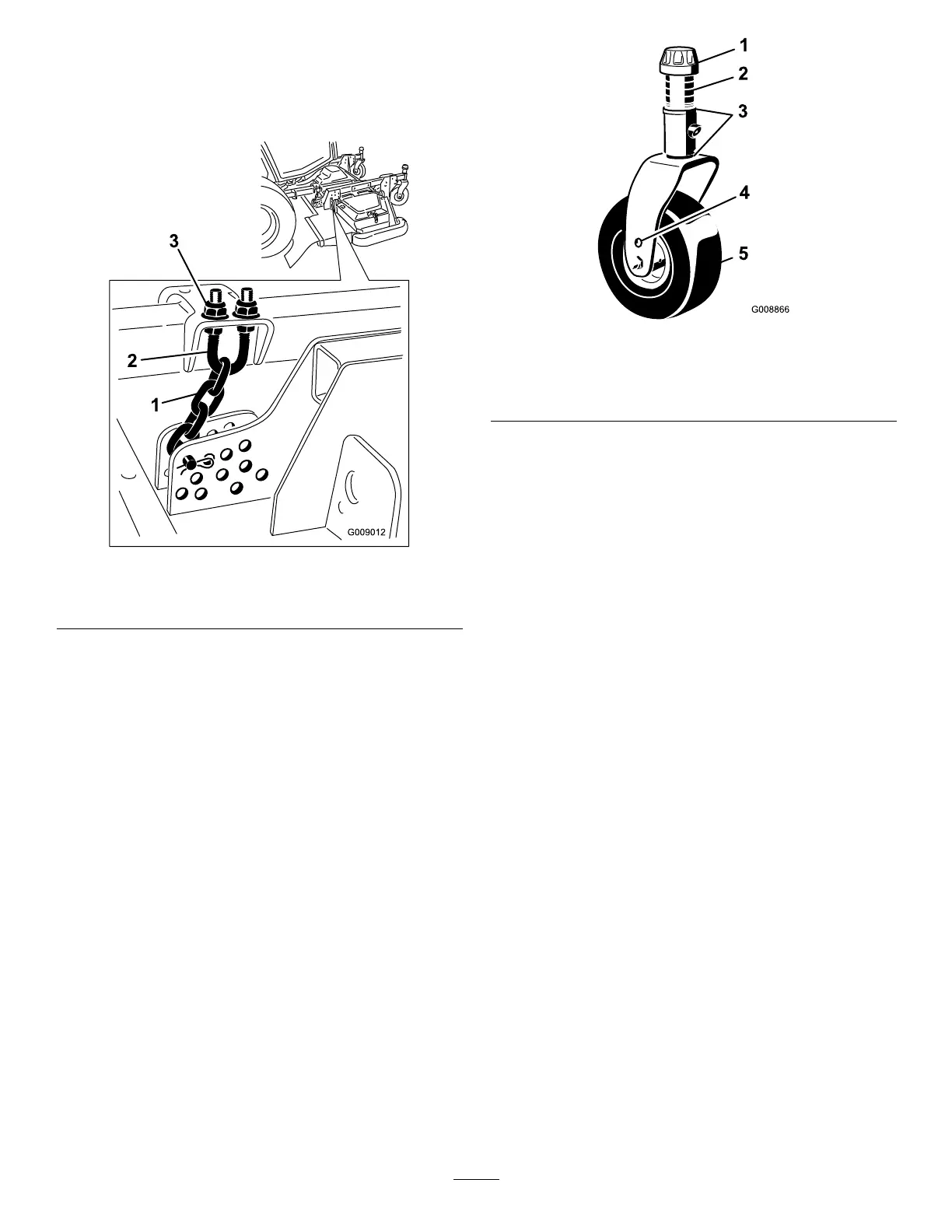

Figure96

1.Tensioningcap4.Topaxlemountinghole

2.Spacers5.Castorwheel

3.Shims

ServicingtheCastorArm

Bushings

Thecastorarmshavebushingspressedintothetopand

bottomofthetubeandaftermanyhoursofoperation,

thebushingswillwear.Tocheckthebushings,movethe

castorforkbackandforthandfromsidetoside.Ifthe

castorspindleislooseinsidethebushings,thebushings

arewornandmustbereplaced.

1.Raisethecuttingunitsothatthewheelsareoffof

theoor.Blockthecuttingunitsothatitcannot

accidentallyfall.

2.Removethetensioningcap,spacer(s),andthrust

washerfromthetopofthecastorspindle.

Note:Recordthepositionofthewashersand

spacersbeforeremovalsothedeckpitchdoesnot

havetobereadjusted.

3.Pullthecastorspindleoutofthemountingtube.

Allowthethrustwasherandspacer(s)toremainon

thebottomofthespindle.

4.Insertapinpunchintothetoporbottomofthe

mountingtubeanddrivethebushingoutofthetube

(

Figure97).Alsodrivetheotherbushingoutofthe

tube.Cleantheinsideofthetubestoremovedirt.

63

Loading...

Loading...