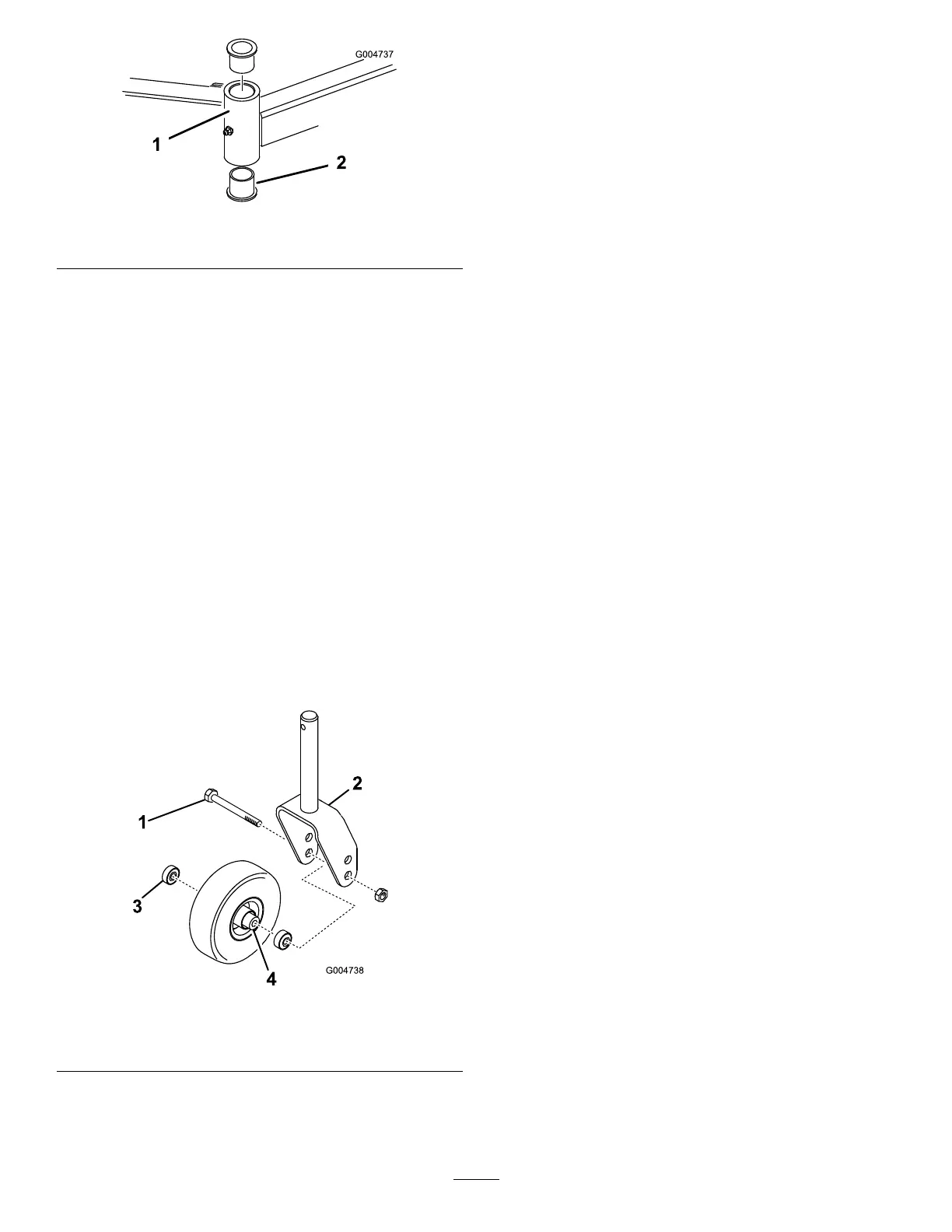

Figure97

1.Castorarmtube

2.Bushings

5.Applygreasetotheinsideandoutsideofthenew

bushings.Usingahammerandatplate,drivethe

bushingsintothemountingtube.

6.Inspectthecastorspindleforwearandreplaceitif

itisdamaged.

7.Pushthecastorspindlethroughthebushingsand

mountingtube.Slidethethrustwasherandspacer(s)

ontothespindle.Installthetensioningcaponthe

castorspindletoretainallpartsinplace.

ServicingtheCastorWheels

andBearings

ServiceInterval:Every500hours—Inspectthecutting

unitcastorwheelassemblies.

1.Removethelocknutfromtheboltholdingthecastor

wheelassemblybetweenthecastorfork(Figure98)

orthecastorpivotarm.Graspthecastorwheeland

slidetheboltoutoftheforkorpivotarm.

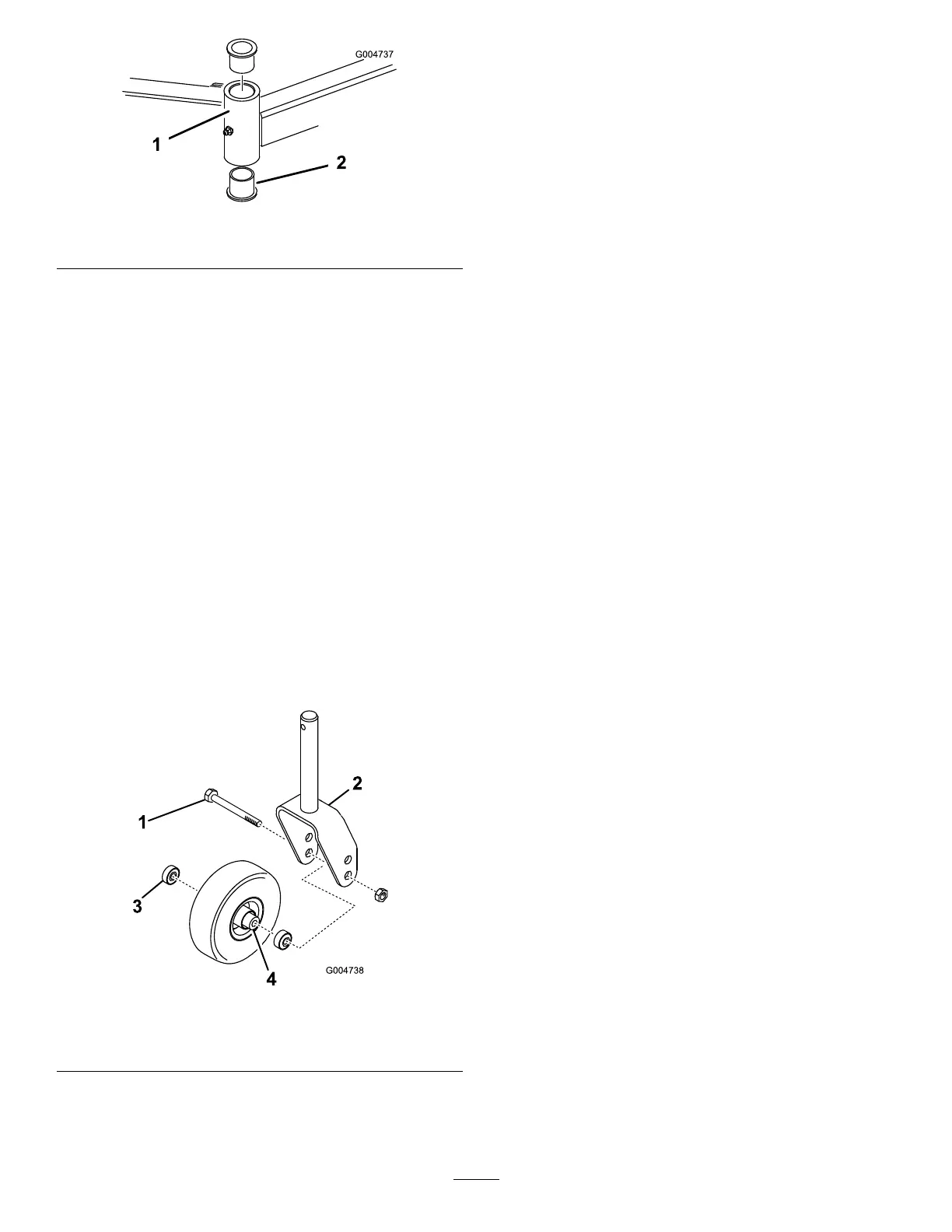

Figure98

1.Castorwheel

3.Bearing

2.Castorfork

4.Bearingspacer

2.Removethebearingfromthewheelhubandallow

thebearingspacertofallout(Figure98).Remove

thebearingfromtheoppositesideofthewheelhub.

3.Checkthebearings,spacer,andinsideofthewheel

hubforwear.Replaceanydamagedparts.

4.Toassemblethecastorwheel,pushthebearinginto

thewheelhub.Wheninstallingthebearings,press

ontheouterraceofthebearing.

5.Slidethebearingspacerintothewheelhub.Pushthe

otherbearingintotheopenendofthewheelhubto

captivatethebearingspacerinsidethewheelhub.

6.Installthecastorwheelassemblybetweenthecastor

forkandsecureitinplacewiththeboltandlocknut.

64

Loading...

Loading...