Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein2/3oz(20ml)

bottles.Onebottleissufcientfor4-6gallons(15-22

1)ofhydraulicoil.Orderpartno.44-2500fromyour

authorizedTorodistributor.

Note:Ifambientoperatingtemperaturesexceed110°

F,contactToroforuidrecommendations.

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,andremovethekey.

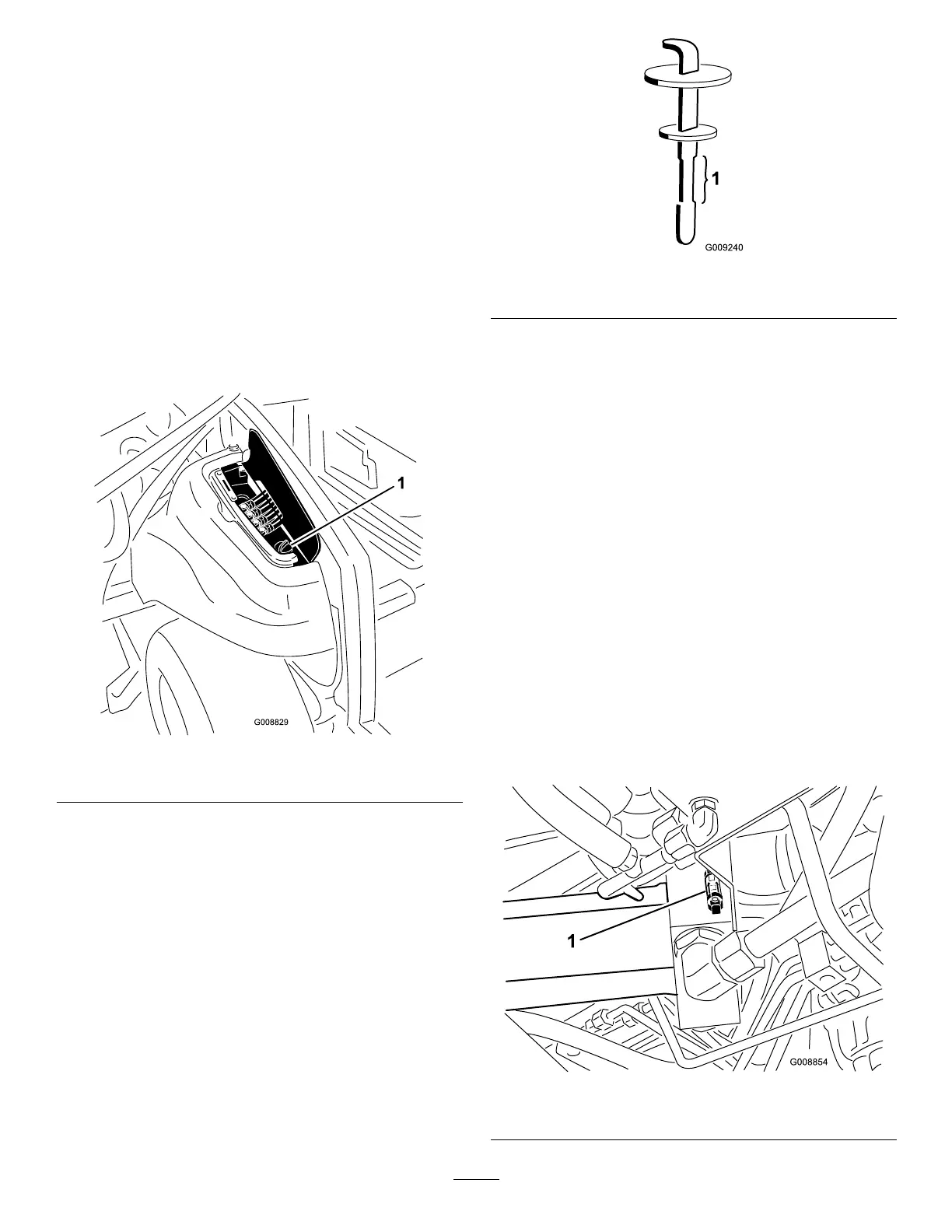

2.Ontherightsideofthemachine,raisetheaccess

covertoexposethehydraulictankcap(

Figure86).

3.Cleantheareaaroundthellerneckandcapofthe

hydraulictank(Figure86).Removethecapfrom

thellerneck.

Figure86

1.Hydraulictankcap

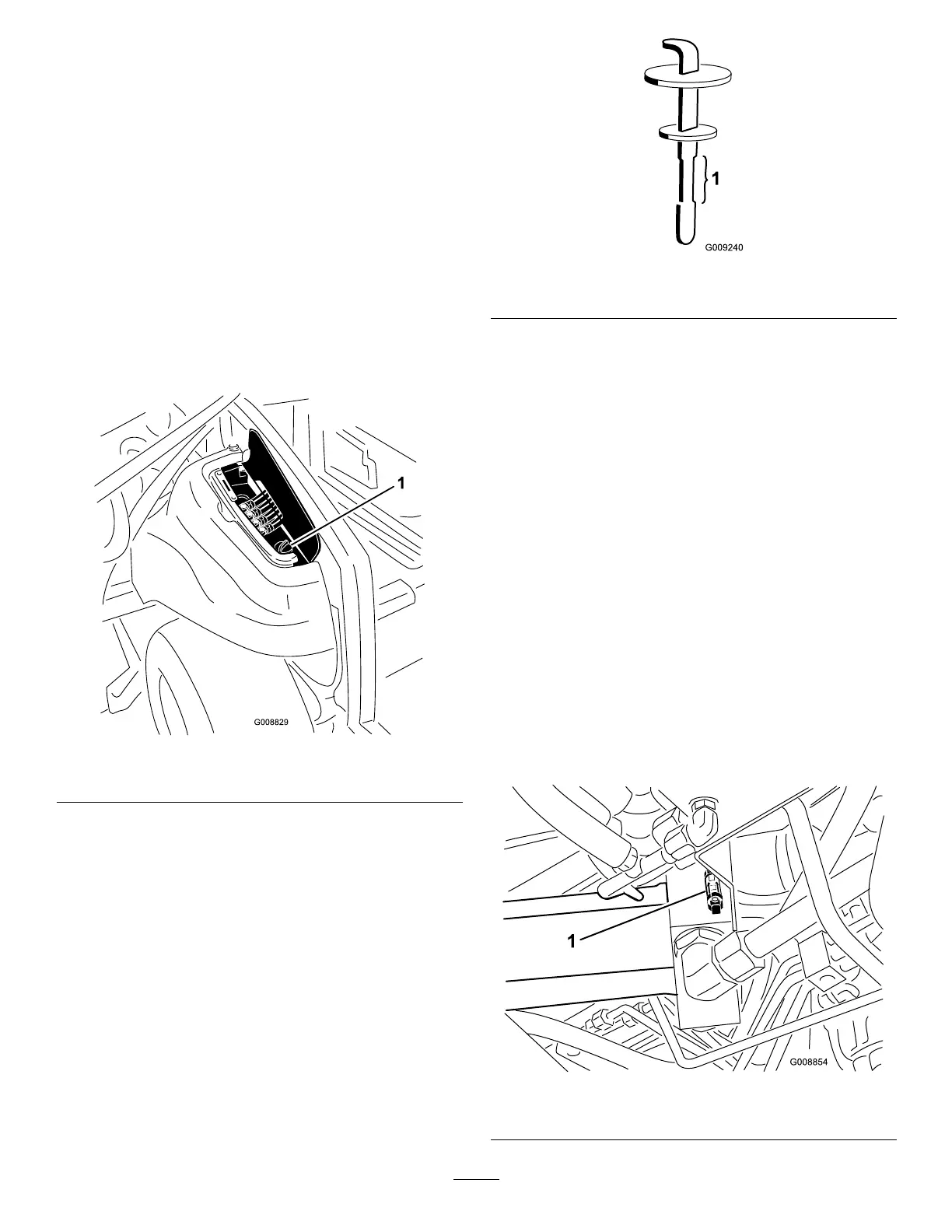

4.Removethedipstickfromthellerneckandwipe

itwithacleanrag.Insertthedipstickintotheller

neck;thenremoveitandchecktheuidlevel.The

uidlevelshouldbewithinthesafeoperatingrange

onthedipstick(

Figure87).

Figure87

1.Safeoperatingrange

5.Ifthelevelislow ,addtheappropriateuidtoraise

theleveltotheuppermark.

6.Installthedipstickandcapontothellerneck.

7.Closethecover.

CheckingtheHydraulicFilter

ServiceIndicators(Ifso

equipped)

ServiceInterval:Every50hours—Checkthehydraulic

lterserviceindicators(2)

Note:Ifalterserviceindicatorismountedontopof

eachltermount,checkthelterindicators(Figure88)

every50hourstoverifythattherearerestrictionsinthe

lters.Iftheyellowplunger(Figure89)intheindicator

movestotheredzone,itistimetochangethelter.

Note:Checktheindicatorwhiletheengineisrunning

athighidleandatoperatingtemperature.

Figure88

1.Hydrauliclterserviceindicators(2)

59

Loading...

Loading...