Important:Useonlythehydraulicuids

specied.Otheruidscouldcausesystem

damage.

8.Installthereservoircap.Starttheengineanduseall

ofthehydrauliccontrolstodistributehydraulicuid

throughoutthesystem.Alsocheckforleaks;then

stoptheengine.

9.Checktheuidlevelandaddenoughtoraiselevel

theleveltotheFullmarkonthedipstick.Donot

overll.

CheckingtheHydraulicLines

andHoses

ServiceInterval:Every2years—Replacemoving

hoses.

Inspectthehydrauliclinesandhosesdailyfor

leaks,kinkedlines,loosemountingsupports,wear,

loosettings,weatherdeterioration,andchemical

deterioration.Makeallnecessaryrepairsbefore

operating.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Makesureallhydraulicuidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingsaretightbeforeapplyingpressureto

thehydraulicsystem.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

•Seekimmediatemedicalattentionifuidis

injectedintoskin.

HydraulicSystemTestPorts

Thetestportsareusedtotestthepressureinthe

hydrauliccircuits.ContactyourlocalTorodistributoror

refertotheToroServiceManualforassistance.

MowerMaintenance

Pivoting(Tilting)theFront

CuttingUnitUpright

Note:Althoughnotneededfornormalmaintenance

procedures,thefrontcuttingunitcanbepivoted(tilted)

toanuprightposition.Shouldyoudesiretotiltthe

cuttingunit,proceedasfollows:

1.Raisethefrontcuttingunitslightlyoffoftheoor,

settheparkingbrake,andstoptheengine.Remove

theignitionkey.

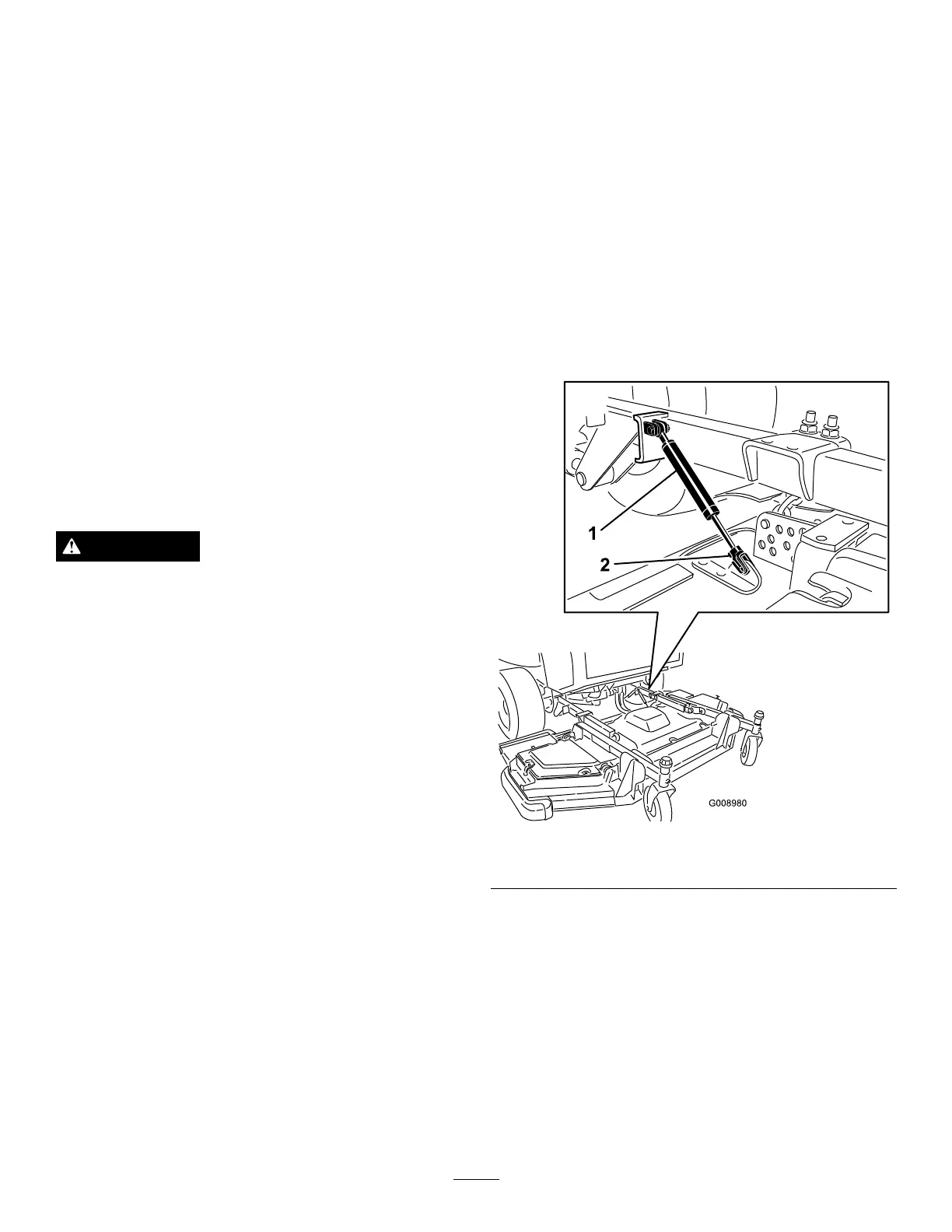

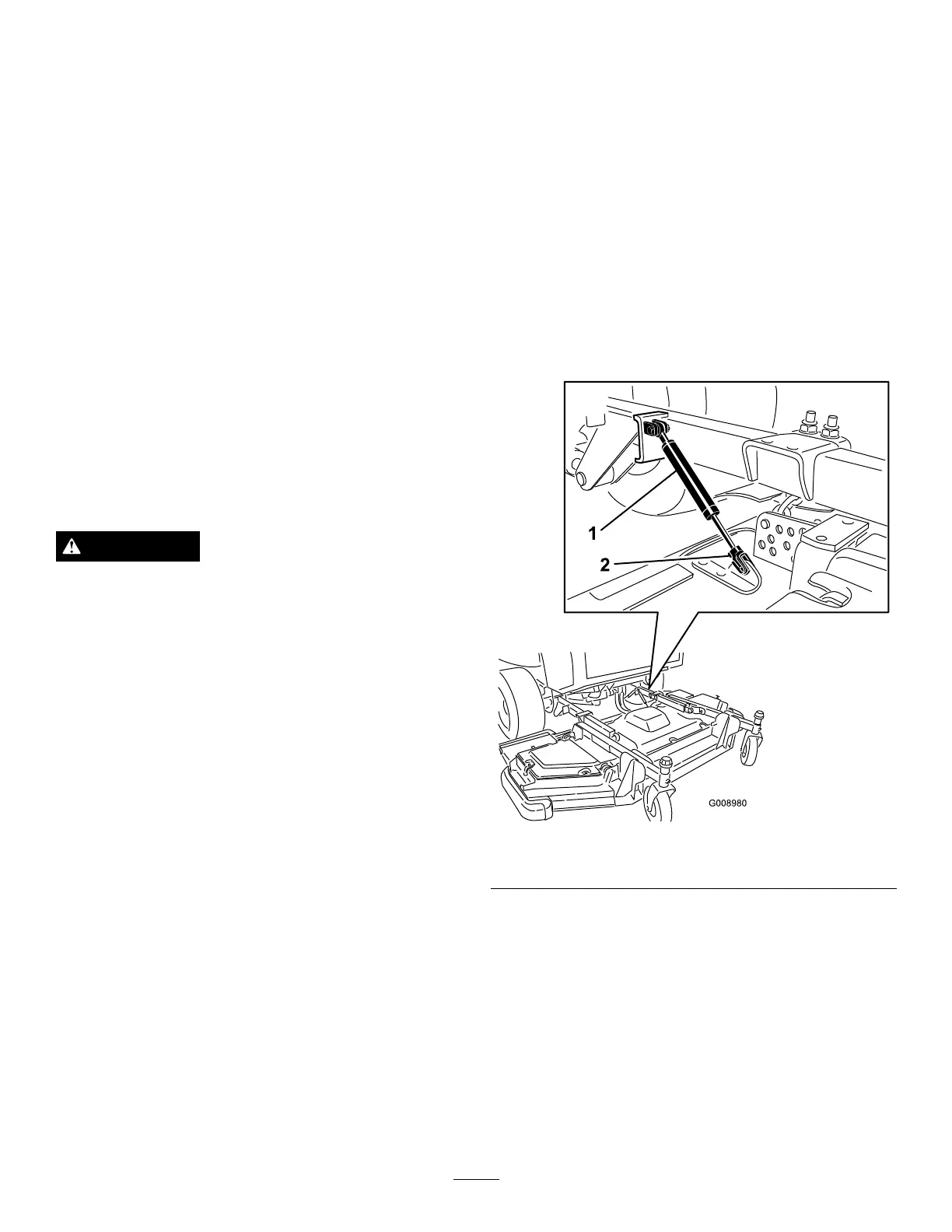

2.Removetheretainerclipanddisconnectthedamper

assemblyfromthecuttingunit(

Figure91).

Figure91

1.Damperassembly2.Retainerclip

3.Removethehairpincotterandclevispinsecuring

theheight-of-cutchainstotherearofthecutting

unit(Figure92).

61

Loading...

Loading...