72

TK 61753-2-MM-EN

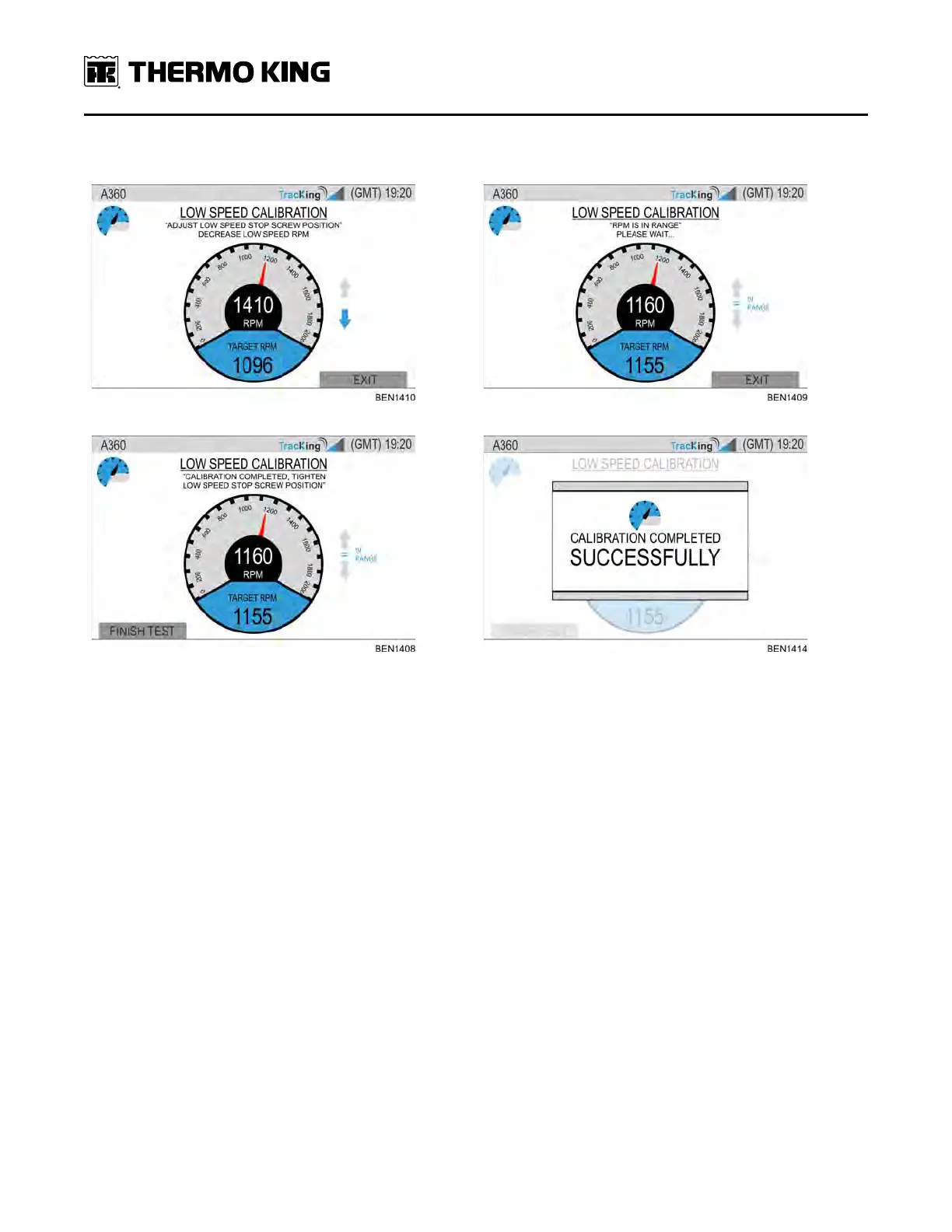

Table 5. Low Speed Stop Screw Position Adjustments

1. 2.

3. 4.

1. Adjust (slightly) the low idle stop screw so that the engine speed target is within 10 RPM of the current engine speed

displayed on the HMI.

• This may be somewhat of an repetitive process

• RPM and Target RPM values should stabilize after 10-20 seconds

• The target RPM value will probably not be the nominal low speed.

• The target RPM is determined by the load on the engine at the time of the test

When the engine speed target is within 10 RPM of the current engine speed for 10 consecutive seconds, the HMI will

display the option to finish test.

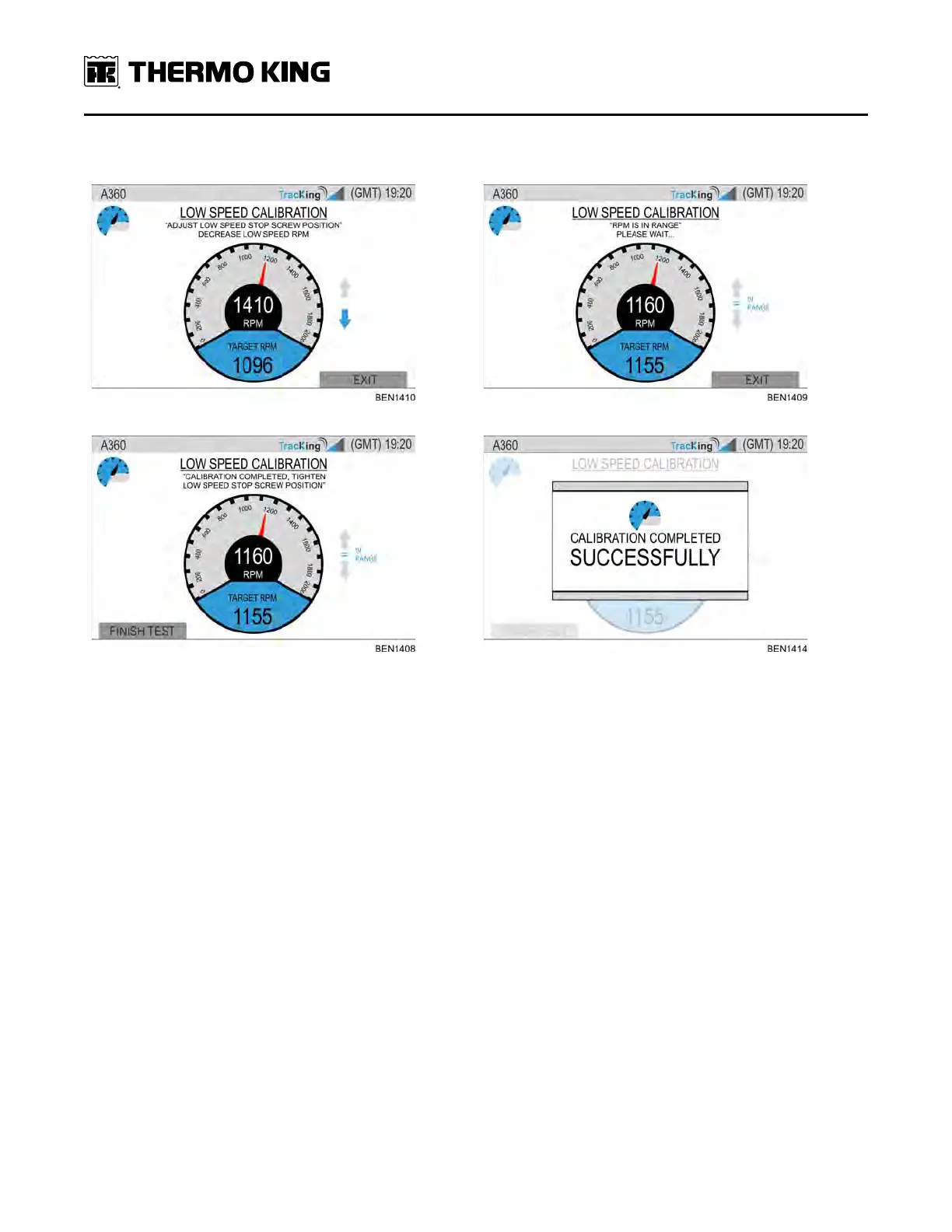

2. Tighten the low speed stop screw position to within 10 RPM.

• Verify via the HMI that the engine speed is still within the desired range after the set screw is locked down.

– This may be somewhat of an repetitive process

• Once satisfied, Select via HMI to Finish Test.

• The HMI will then complete the calibration test and auto restart the unit.

EEnnggiinnee MMaaiinntteennaannccee

Loading...

Loading...