36

RTHD-SVX01L-EN

Installation Electrical

General Recommendations

As you review this manual, keep in mind that:

• All field-installed wiring must conform to National

Electric Code (NEC) guidelines, and any applicable

state and local codes. Be sure to satisfy proper

equipment grounding requirements per NEC.

• Compressor motor and unit electrical data is listed on

the chiller nameplate.

• All field-installed wiring must be checked for proper

terminations, and for possible shorts or grounds.

• For proper electrical component operation, do not

locate the unit in areas exposed to dust, dirt, corrosive

fumes, or excessive humidity. If any of these conditions

exist, corrective action must be taken.

Notes:

• Always refer to wiring diagrams shipped with

chiller or unit submittal for specific electrical

schematic and connection information.

• All conduit must be long enough to allow

compressor and starter removal.

WARNING

Proper Field Wiring and Grounding

Required!

Failure to follow code could result in death or serious

injury.

All field wiring MUST be performed by qualified

personnel. Improperly installed and grounded field

wiring poses FIRE and ELECTROCUTION hazards. To

avoid these hazards, you MUST follow requirements

for field wiring installation and grounding as

described in NEC and your local/state/national

electrical codes.

WARNING

Hazardous Voltage w/Capacitors!

Failure to disconnect power and discharge capacitors

before servicing could result in death or serious

injury.

Disconnect all electric power, including remote

disconnects and discharge all motor start/run

capacitors before servicing. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized. For variable frequency drives

or other energy storing components provided by

Trane or others, refer to the appropriate

manufacturer’s literature for allowable waiting periods

for discharge of capacitors. Verify with a CAT III or IV

voltmeter rated per NFPA 70E that all capacitors have

discharged.

Important: Do not allow conduit to interfere with other

components, structural members or

equipment. Control voltage (115V) wiring in

conduit must be separate from conduit

carrying low voltage (<30V) wiring. To prevent

control malfunctions, do not run low voltage

wiring (<30 V) in conduit with conductors

carrying more than 30 volts.

Electrical Data

Standard Units with Wye-Delta Starter

See “Electrical Data Table Information,” p. 37. Electrical

component sizing should be based on actual jobsite

operating conditions. This factor can be obtained through

the use of TOPSS™.

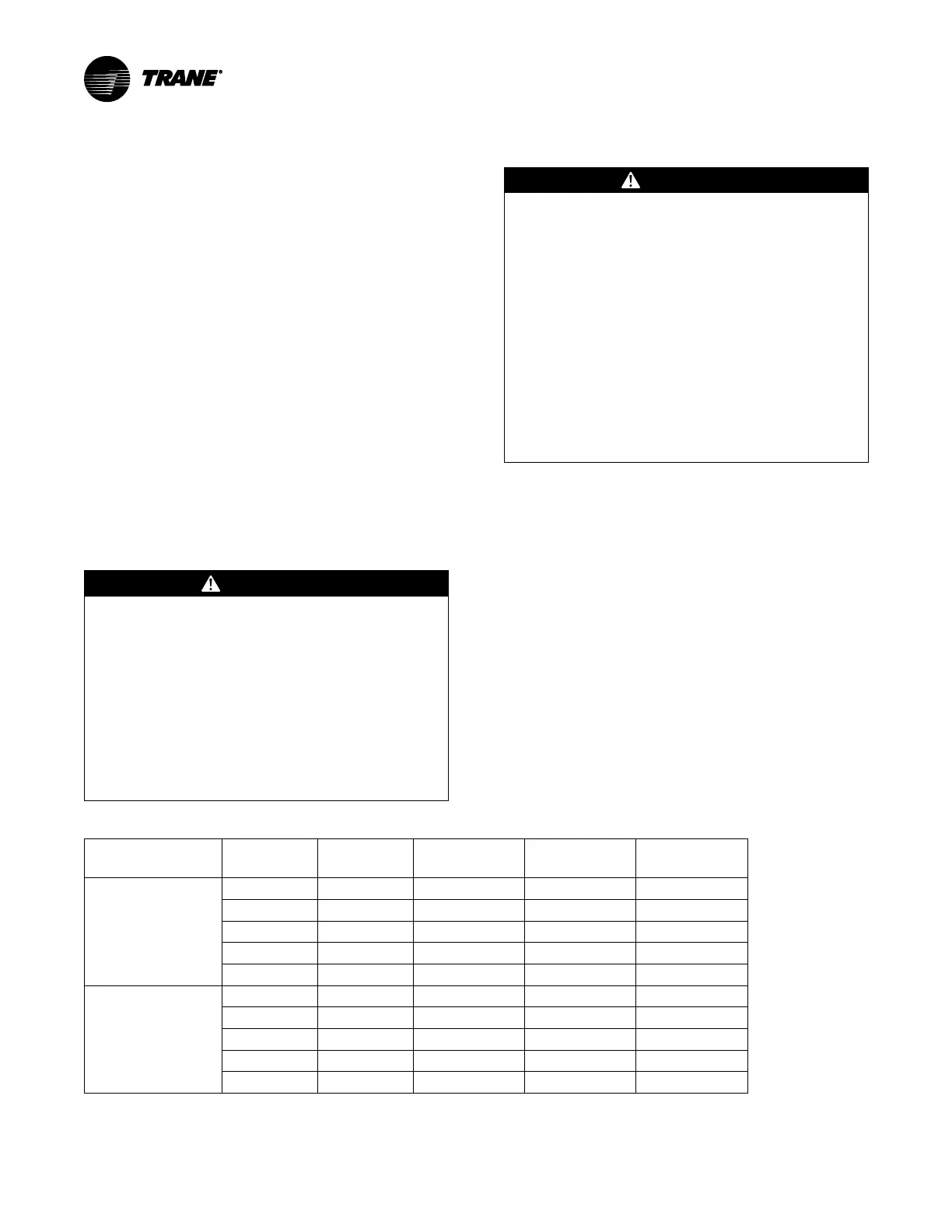

Table 9. Compressor motor electrical data (60 Hz) — standard units (wye-delta starter)

Compressor Code

(a)

Voltage

(b)

Max kW

RLA @

Max kW

(c)

LRA

(Wye)

LRA

(Delta)

B1, B2

200 174 557 970 3103

230 174 484 818 2617

380 174 291 488 1561

460 174 241 400 1280

575 174 193 329 1053

C1, C2

200 249 812 1173 3634

230 249 698 936 2901

380 249 421 558 1727

460 249 349 469 1453

575 249 279 375 1162

Loading...

Loading...