RTHD-SVX01L-EN

49

Refrigeration Cycle

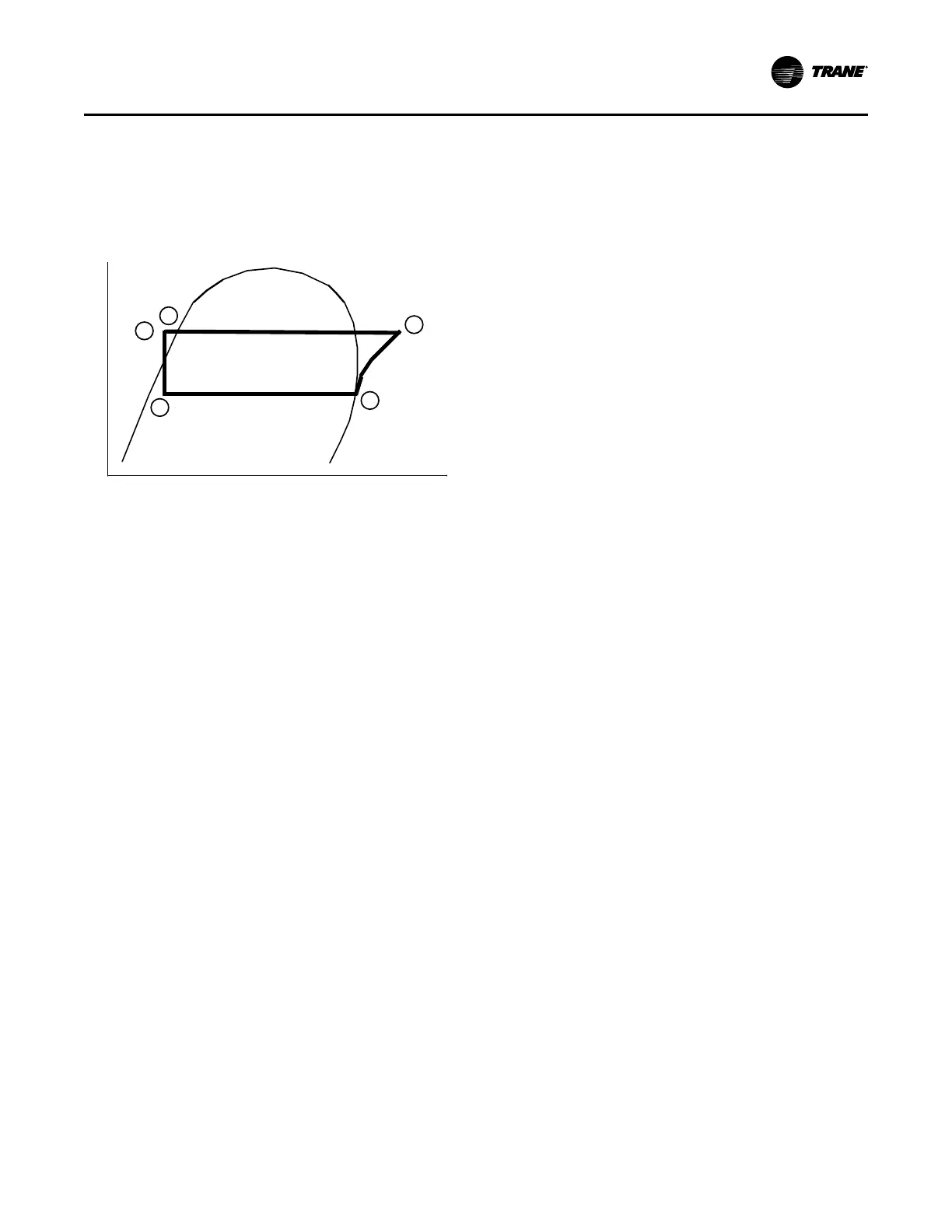

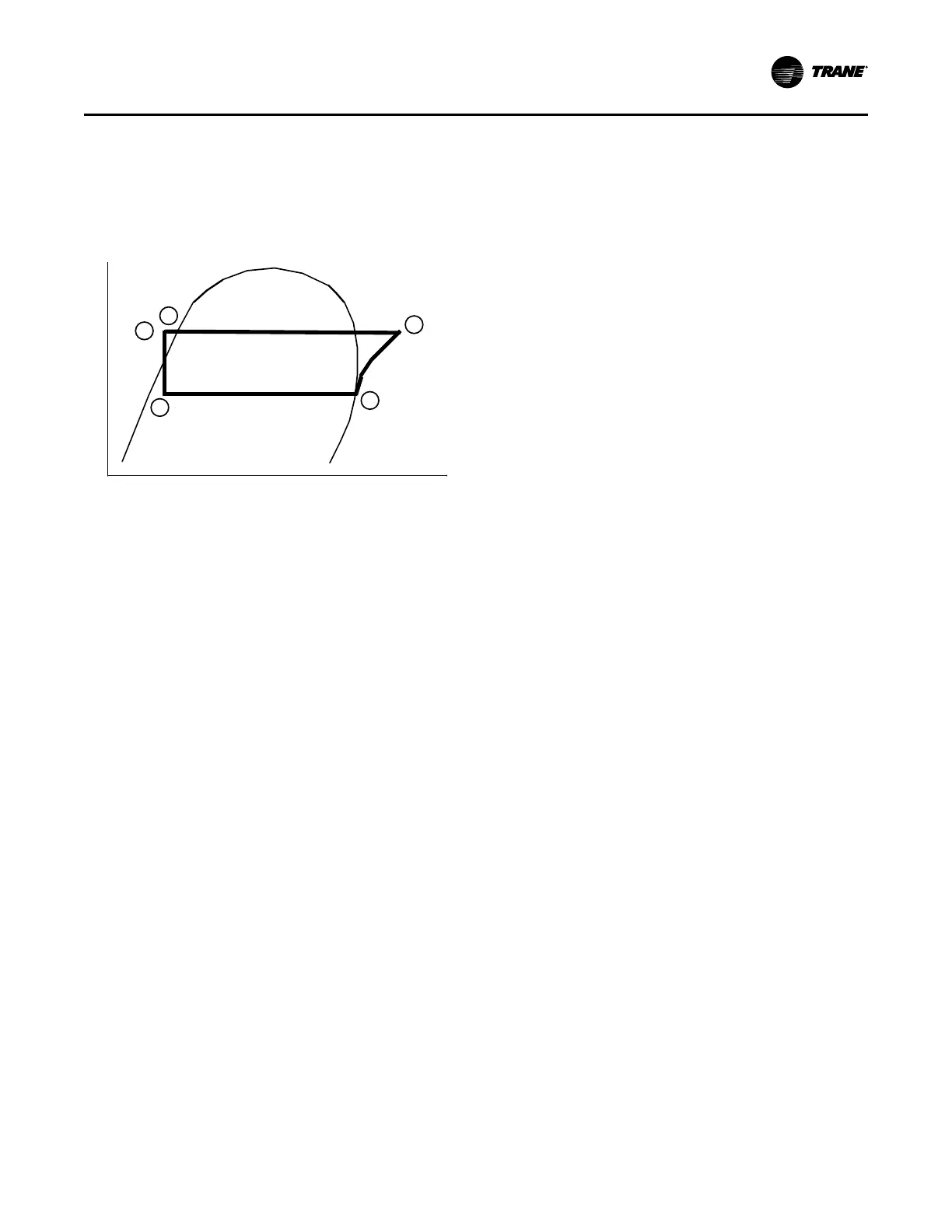

The refrigeration cycle can be described using the

pressure-enthalpy diagram shown in Figure 23, p. 49. Key

State Points are indicated on the figure and are referenced

in the discussion following.

Figure 23. Pressure/enthalpy curve

Pressure

Enthalpy

Liquid

1

3

5

2

4

The Optimus™ chiller makes use of a shell-and-tube

evaporator design with refrigerant evaporating on the shell

side and water flowing inside tubes having enhanced

surfaces. Refrigerant vapor leaves the evaporator as

saturated vapor (State Pt. 1).

The refrigerant vapor generated in the evaporator flows to

the suction end of the compressor. The compressor is a

twin-rotor helical rotary type. The refrigerant flows across

the motor, providing the necessary cooling, then enters the

compression chamber. Refrigerant is compressed in the

compressor to discharge pressure conditions.

Simultaneously, lubricant is injected into the compressor.

An oil management system provides an almost oil-free

refrigerant to the shells to maximize heat transfer

performance, while providing lubrication and rotor sealing

to the compressor. The lubrication system ensures long

compressor life and contributes to quiet operation.

Immediately following the compression process the

lubricant and refrigerant are effectively divided using an oil

separator.

The oil-free refrigerant vapor enters the condenser at State

Pt. 2. Condensing is accomplished in a shell-and-tube heat

exchanger where refrigerant is condensed on the shell side

and water flows internally in the tubes. Cooling tower water,

circulating through the condenser tubes, absorbs heat from

this refrigerant and condenses it.

As the refrigerant leaves the bottom of the condenser

(State Pt. 3), it enters an integral subcooler where it is

subcooled before traveling to the electronic expansion

valve (State Pt. 4). The pressure drop created by the

expansion process vaporizes a portion of the liquid

refrigerant.

The resulting mixture of liquid and gaseous refrigerant then

enters the Evaporator Distribution system (State Pt. 5). The

flash gas from the expansion process is internally routed to

compressor suction, and while the liquid refrigerant is

distributed over the tube bundle in the evaporator.

Refrigeration Circuit

Each unit has a single refrigerant circuit that includes

compressor suction and discharge service valves,

removable core filter, charging port, and sight glass. An

electronically controlled expansion valve is provided to

maintain variable capacity modulation over the entire

building load and maintain proper refrigerant flow.

Compressor and Motor

Each RTHD is equipped with a semi-hermetic, direct-drive,

3600 rpm 60 Hz (3000 rpm 50 Hz) rotary compressors that

includes a capacity control slide valve, oil sump heater, and

differential pressure refrigerant oil flow system. The

optional AFD provides additional capacity control with

modulating speed. Four pressure-lubricated rolling element

bearing groups support the rotary assembly. The motor is a

suction gas-cooled, hermetically sealed, two-pole squirrel

cage induction motor.

Evaporator and Condenser

Heat exchangers are shell and tube design. Standard

tubes are externally finned, internally enhanced seamless

copper with lands at all tube sheets. All tube sheets are

made of carbon steel. Tubes are mechanically expanded

into tube sheets and mechanically fastened to tube

supports. Evaporator tubes are 1.0- inch (25.4 mm)

diameter and condenser tubes are 0.75-inch (19.05 mm)

diameter. All tubes can be individually replaced.

Shells are carbon steel plate. The evaporator and

condenser are designed, tested, and stamped in

accordance with ASME Code for refrigerant-side/ working-

side pressure of 200 psig (13.8 bars).

All water pass arrangements are available with grooved

connections (150 or 300 psig waterside working pressure).

All connections may be either right- or left-handed.

Waterside shall be hydrostatically tested at 1.5X design

working pressure.

Oil Management

The unit is configured with an oil management system that

ensures proper oil circulation throughout the unit. The key

components of the system include an oil separator, oil filter,

oil sump and oil sump heater. An optional oil cooler is

installed when the unit is used for high condensing

temperature or low evaporator temperature conditions.

Unit-Mounted Starter

A unit-mounted starter and control panel is provided on

every chiller. The Symbio™ 800 provides for accurate

chilled water control as well as monitoring, protection and

adaptive limit functions. The “adaptive” nature of the

Operating Principles

Loading...

Loading...