RTHD-SVX01L-EN

45

External Chilled Water Setpoint - Optional

Symbio 800 will accept either a 2-10 Vdc or a 4-20 mA

input (J9-4, J9-5) signal, to adjust chilled water setpoint

remotely.

External Demand Limit Setpoint - Optional

Symbio 800 will accept either a 2-10Vdc or a 4-20mA input

(J7-11, J7-12) signal to adjust the demand limit setpoint

from a remote location.

Percent Condenser Pressure Output -

Optional

Symbio 800 provides a 2-10 Vdc analog output to indicate

percent High Pressure Cutout (HPC) condenser pressure.

Percent HPC = (Condenser Pressure/High Pressure

Cutout Setpoint)*100

Compressor Percent RLA Output - Optional

Symbio 800 provides a 2-10 Vdc analog output to indicate

%RLA of compressor starter average phase current. The

values of 2 to 10 Vdc correspond to 0 to 120% RLA.

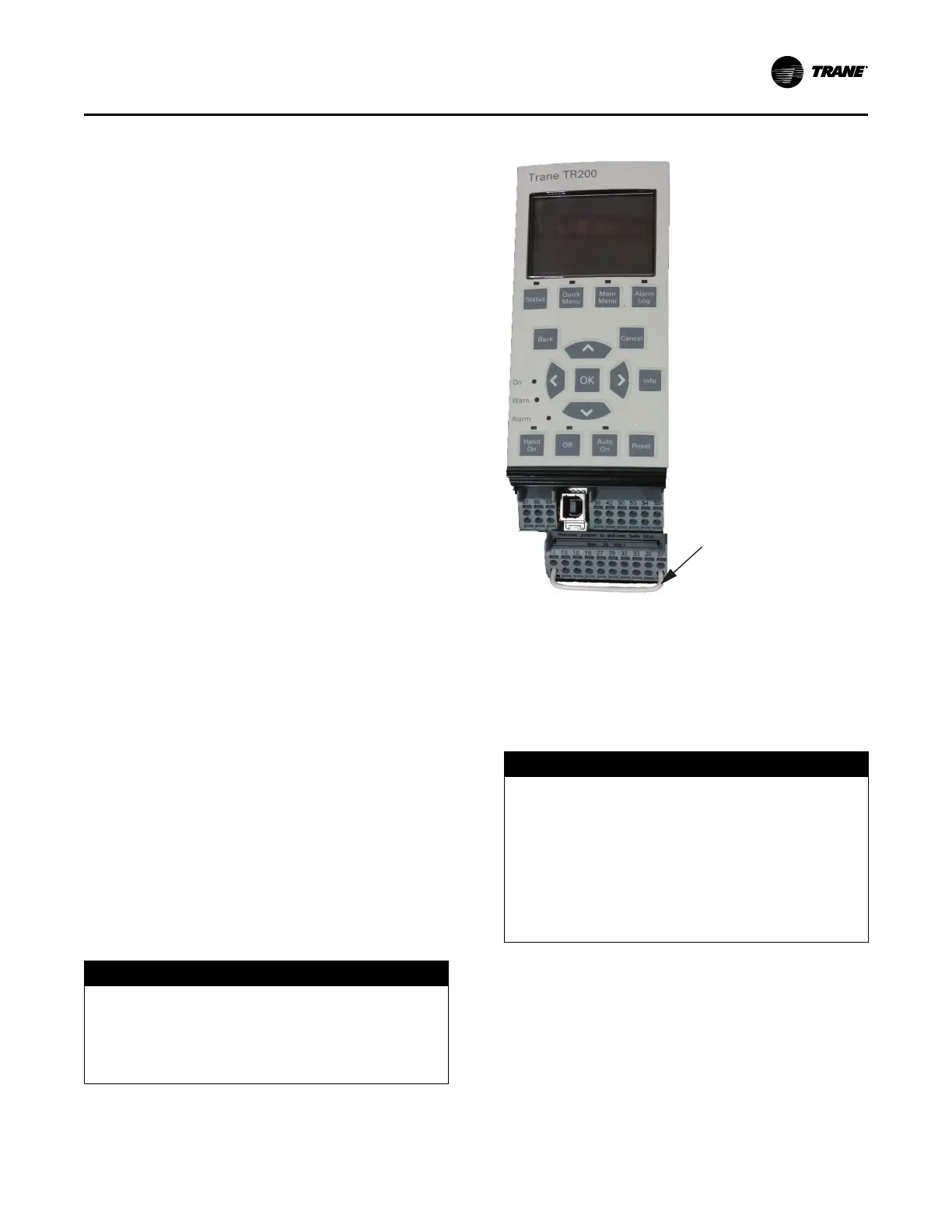

AFD Drive (Optional)

Trane TR200 drive is an electronic motor controller that

converts AC mains input into a variable AC waveform

output. The frequency and voltage of the output are

regulated to control the motor speed or torque.

TR200 drive includes the following features:

• Soft start to minimize inrush current

• Improved harmonic mitigation with DC link reactor

• Integrated power fuse

• Graphical LCD keypad

• Unit Mounted with factory pre-wiring

• ‘Trane Drive Utility’ for configuration and tracking

See Service Manual, BAS-SVM01*-EN, TR200 New D-

Frame for more information.

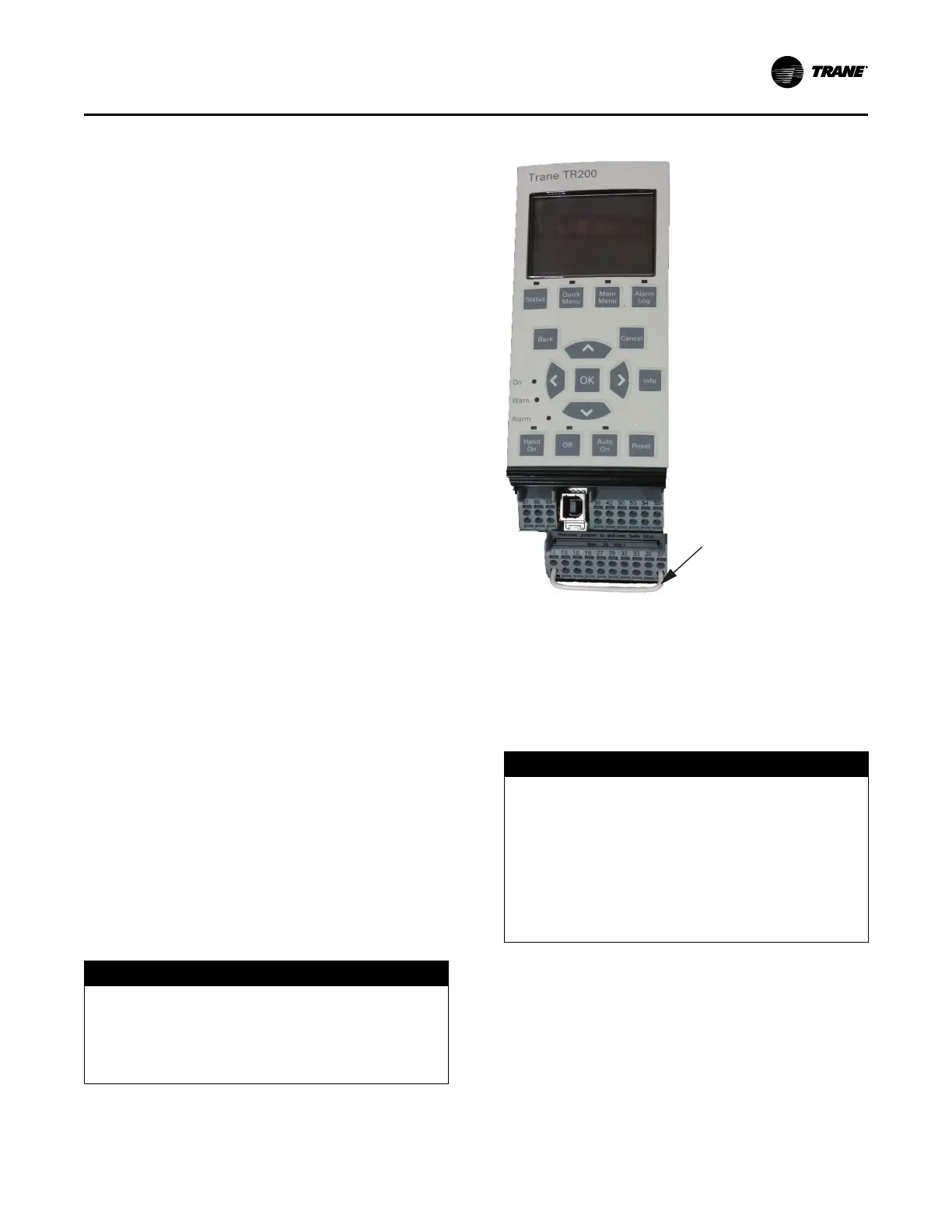

AFD Drive Installation

The AFD drive is manufactured with a jumper installed

between terminal 12 (+24Vdc source) and terminal 37

(Safe Stop digital input). This jumper must be removed

prior to unit operation. See Figure 21, p. 45 for view of

jumper as it would be installed on drive from manufacturer.

NOTICE

Equipment Damage!

Failure to follow instructions below could result in

equipment damage.

Verify/remove jumper between AFD terminals 12 and

37 before unit operation.

Figure 21. AFD jumper

Jumper between

terminals 12 and 37

must be removed

prior to unit

operation.

Important:

• For factory provided AFD units, verify

jumper has been removed.

• For field installed drives, remove jumper

shown in Figure 21, p. 45.

AFD Drive Programming

NOTICE

Equipment Damage!

Changing default clockwise phase rotation or

enabling phase reversal protection could prevent

proper chiller operation or cause equipment damage.

• Do NOT change Adaptive Frequency™ drive

(AFD) phase rotation to counterclockwise.

• Do NOT enable phase reversal protection.

Field replacement drives must be programmed via the

keypad interface. Program non-compressor specific

parameters first in sequential order (), followed by

compressor specific parameters (see Table 14, p. 46) in

sequential order.

Installation Electrical

Loading...

Loading...