68

RTHD-SVX01L-EN

Table 16, p. 68 and list baseline measurements for

Optimus™ units running at AHRI standard operating

conditions. If chiller measurements vary significantly from

values listed below, problems may exist with refrigerant

and oil charge levels. Contact Trane service.

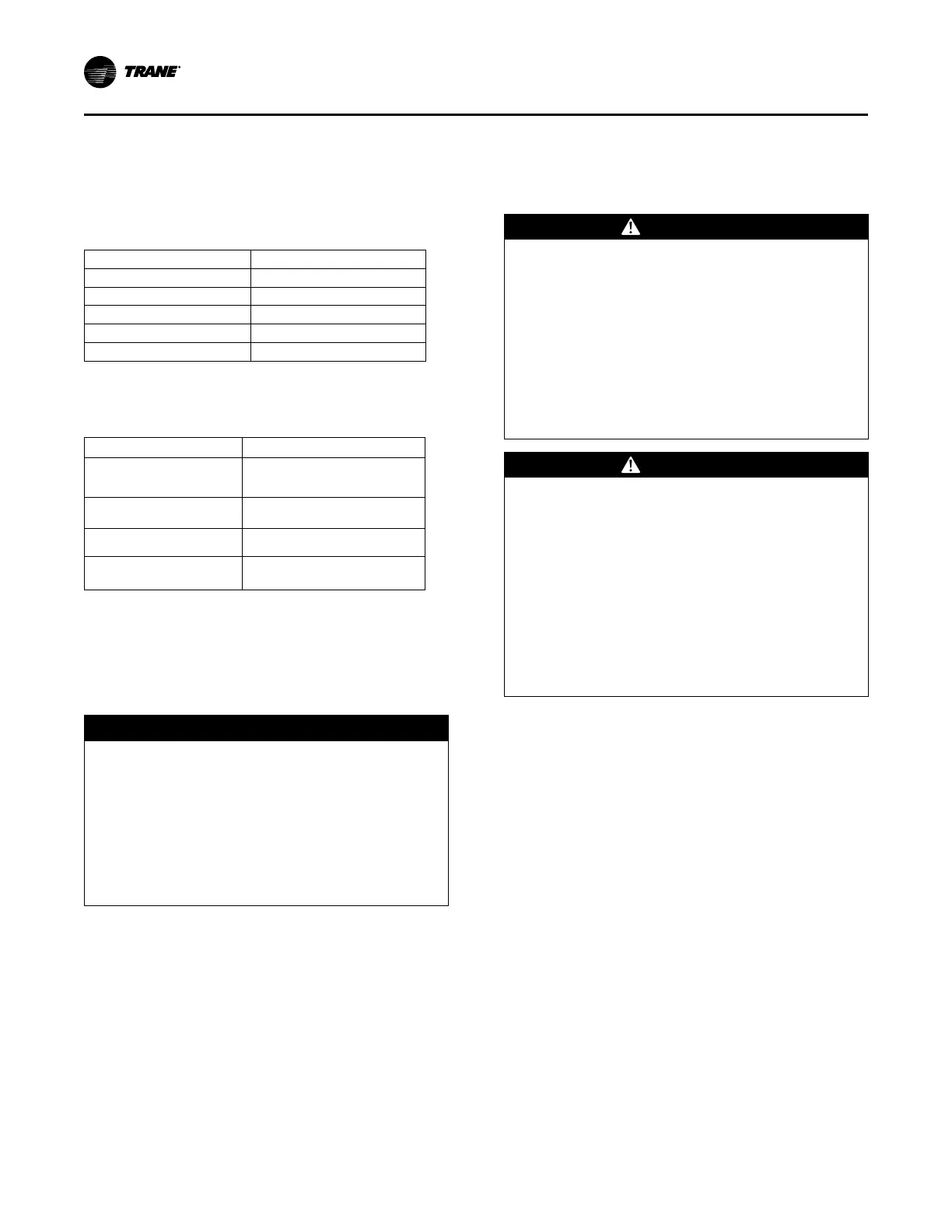

Table 16. Operating conditions at full load

Description

Condition

Evaporator pressure 40-55 psig

Condensing pressure 85-120 psig

Discharge superheat

17°F

Subcooling

5-10°F

EXV percent open 40-50% open in Auto mode

Note: All conditions stated above are based on the unit running fully

loaded at AHRI conditions. If full load conditions cannot be met,

contact Trane service.

Table 17. Operating conditions at minimum load

Description

Condition

Evaporator approach

less than 7°F

(a)

(non-glycol

applications)

Condensing approach

less than 7°F

(a)

Subcooling

2-3°F

EXV percent open 10-20 % open

Note: Conditions at minimum must be: entering condenser water: 85°F

and entering evaporator water: 55°F

(a)

~1.0°F for new unit.

Maintenance Procedures

Cleaning the Condenser

NOTICE

Proper Water Treatment Required!

The use of untreated or improperly treated water

could result in scaling, erosion, corrosion, algae or

slime.

Use the services of a qualified water treatment

specialist to determine what water treatment, if any, is

required. Trane assumes no responsibility for

equipment failures which result from untreated or

improperly treated water, or saline or brackish water.

Condenser tube fouling is suspect when the “approach”

temperature (i.e., the difference between the refrigerant

condensing temperature and the leaving condenser water

temperature) is higher than predicted.

Standard water applications will operate with less than a

10°F approach. If the approach exceeds 10°F, cleaning the

condenser tubes is recommended.

Note: Glycol in the water system typically doubles the

standard approach.

If the annual condenser tube inspection indicates that the

tubes are fouled, two cleaning methods can be used to rid

the tubes of contaminants. The methods are:

Mechanical Cleaning Procedure

Mechanical tube cleaning this method is used to remove

sludge and loose material from smooth-bore condenser

tubes.

WARNING

Heavy Object!

Failure to follow instructions below could result in

unit dropping which could result in death or serious

injury, and equipment or property-only damage.

Ensure that all the lifting equipment used is properly

rated for the weight of the unit being lifted. Each of the

cables (chains or slings), hooks, and shackles used to

lift the unit must be capable of supporting the entire

weight of the unit. Lifting cables (chains or slings)

may not be of the same length. Adjust as necessary

for even unit lift.

WARNING

Straight Vertical Lift Required!

Failure to properly lift waterbox in straight vertical lift

could cause the eyebolts to break which could result

in death or serious injury from object dropping.

The proper use and ratings for eyebolts can be found

in ANSI/ASME standard B18.15. Maximum load rating

for eyebolts are based on a straight vertical lift in a

gradually increasing manner. Angular lifts will

significantly lower maximum loads and should be

avoided whenever possible. Loads should always be

applied to eyebolts in the plane of the eye, not at

some angle to this plane.

Waterbox Removal

Review mechanical room limitations and determine the

safest method or methods of rigging and lifting the

waterboxes.

Important:

• Do not rotate water boxes. See Figure 14,

p. 29 through Figure 16, p. 30 for correct

orientation of the water inlet and outlet.

• Be certain to replace water boxes right-

side-up to maintain proper baffle

orientation. Use new o-rings.

1. Determine the size of chiller being serviced. See unit

nameplate located on chiller control panel.

2. Select the proper lift connection device from . The rated

lifting capacity of the selected lift connection device

must meet or exceed the published weight of the

waterbox found in .

3. Ensure the lift connection device has the correct

connection for the waterbox. Example: thread type

(course/fine, English/metric). Bolt diameter (English/

metric).

Maintenance

Loading...

Loading...