70

RTHD-SVX01L-EN

Oil Sump Level Check

Running the chiller at minimum load is the best for the

quickest return of oil to the separator and sump. The

machine still needs to sit for approximately 30 minutes

before the level is taken. At minimum load, the discharge

superheat should be highest. The more heat in the oil as it

lays in the sump, the more refrigerant will boil off in the

sump and leave more concentrated oil.

The oil level in the oil sump can be measured to give an

indication of the system oil charge. Follow the procedures

below to measure the level.

1. Run the unit fully unloaded for approximately 20

minutes.

2. Cycle the compressor off line.

NOTICE

Equipment Damage!

Operating compressors with service valves open will

result in severe oil loss and equipment damage.

Never operate the compressor with the sight glass

service valves opened. Close the valves after

checking the oil level.

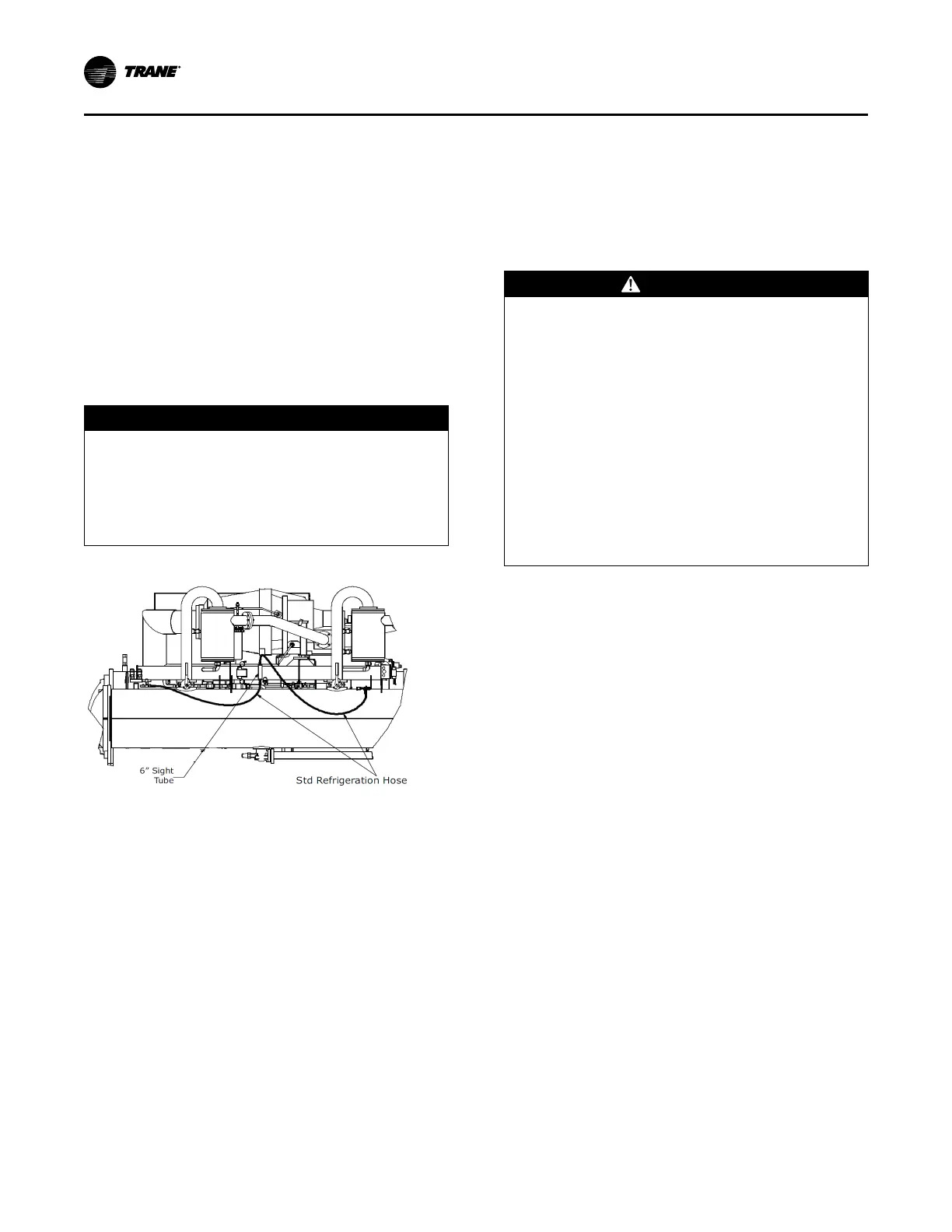

Figure 40. Determining oil level in sump

3. Attach standard refrigeration hose with a sight tube in

the middle to the oil sump drain valve and the

condenser service valve at the top of the condenser.

Using high pressure rated clear hose with appropriate

fittings can help speed up the process.

Note: A shutoff valve at one end of the hose is

recommended to facilitate hose drainage after oil

level check is completed.

4. After the unit is off line for 30 minutes, move the

sightglass along the side of the oil sump.

5. The level should be between 2 inch and 5 inch from the

bottom of the oil sump.

Note: If oil levels are not between 2 inch and 5 inch,

contact Trane service.

Optional AFD Periodic Maintenance and

Inspection

AFD periodic maintenance and inspections should be

performed every 1–12 months, depending on operating

environment.

Visual Inspection — Power Removed

WARNING

Hazardous Voltage w/Capacitors!

Failure to disconnect power and discharge capacitors

before servicing could result in death or serious

injury.

Disconnect all electric power, including remote

disconnects and discharge all motor start/run

capacitors before servicing. Follow proper lockout/

tagout procedures to ensure the power cannot be

inadvertently energized. For variable frequency drives

or other energy storing components provided by

Trane or others, refer to the appropriate

manufacturer’s literature for allowable waiting periods

for discharge of capacitors. Verify with a CAT III or IV

voltmeter rated per NFPA 70E that all capacitors have

discharged.

1. Ensure the door interlocks are present and working.

2. Verify the safety ground connections to the door panels

are securely connected.

3. Inspect power wire cables and devices to assure no

abrasion is occurring from vibrations against chassis of

cabinets, or other edges.

4. Ensure the drive interior and exterior is clear of any

dust or debris. Fans, circuit boards, vents etc. must be

clean.

Important: Only use a vacuum for cleaning. DO NOT

use compressed air.

5. Inspect the interior of the drive for any signs of moisture

entry or leakage.

6. Visually inspect all drive components and wiring. Look

for signs of heat or failure (look for swelled or leaking

capacitors, discolored reactors or inductors, broken

pre-charge resistors, smoke or arc trails on MOVs and

capacitors, etc.).

7. Closely inspect the motor terminal board for any signs

of leakage, arcing, etc.

8. Check ALL cable/lug/terminal connections inside the

drive enclosure. Ensure all are clean and tight, and not

rubbing against each other anywhere.

Maintenance

Loading...

Loading...