34

RTHD-SVX01L-EN

18, p. 34. See Table 7, p. 34 for types and quantities of

insulation required.

Notes:

• Liquid line filter, refrigerant charging valves,

water temperature sensors, drain and vent

connections when insulated must remain

accessible for service.

• Use only water-base latex paint on factory-

applied insulation. Failure to do so may result in

insulation shrinkage.

• Units in environments with higher humidity or

very low leaving water temperature may require

thicker insulation.

Figure 18. Typical RTHD insulation requirement

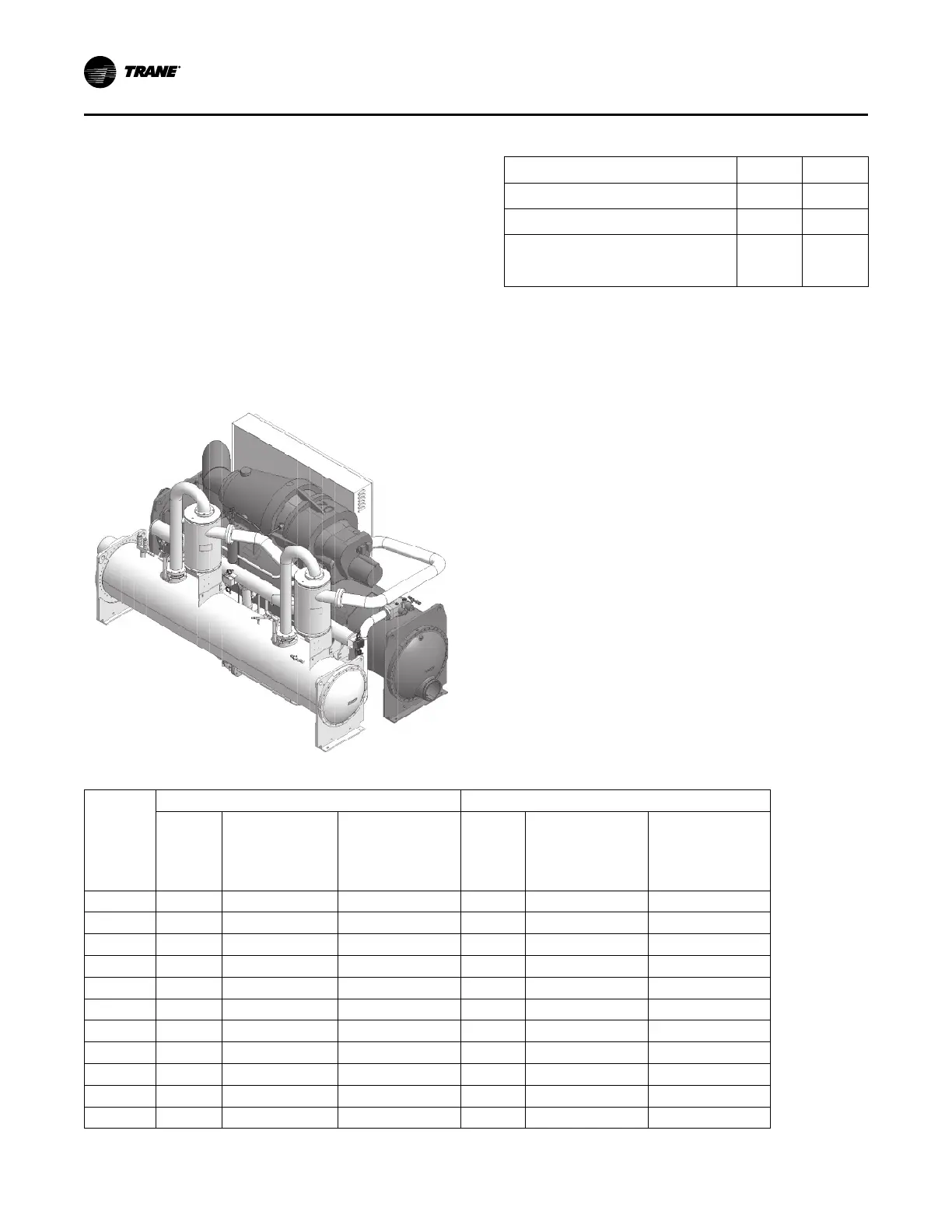

Table 7. Recommended insulation types

Location

Type Sq. Feet

Evaporator

3/4" wall 90

Compressor

3/4" wall 25

All components and piping on low side of

system (gas pump, return oil line, filter from

pump)

3/4" wall 160

Freeze Protection

For unit operation in a low temperature environment,

adequate protection measures must be taken against

freezing. Adjusted settings and recommended ethylene

glycol solution strengths are contained in below table as

follows:

Table 8. Freeze protection settings

Glycol

Percentage

(%)

Ethylene Glycol Propylene Glycol

Solution

Freeze

Point (°F)

Minimum

Recommended Low

Refrigerant Temp

Cutout (°F)

Minimum

Recommended

Leaving Water Temp

Cutout (°F)

Solution

Freeze

Point (°F)

Minimum

Recommended Low

Refrigerant Temp

Cutout (°F)

Minimum

Recommended

Leaving Water Temp

Cutout (°F)

0 32.0 28.6 35.0 32.0 28.6 35.0

2 31.0 27.6 34.0 31.0 27.6 34.0

4 29.7 26.3 32.7 29.9 26.5 32.9

5 29.0 25.6 32.0 29.3 25.9 32.3

6 28.3 24.9 31.3 28.7 25.3 31.7

8 26.9 23.5 29.9 27.6 24.2 30.6

10 25.5 22.1 28.5 26.4 23.0 29.4

12 23.9 20.5 26.9 25.1 21.7 28.1

14 22.3 18.9 25.3 23.8 20.4 26.8

15 21.5 18.1 24.5 23.1 19.7 26.1

16 20.6 17.2 23.6 22.4 19.0 25.4

Installation Mechanical

Loading...

Loading...