RTHD-SVX01L-EN

23

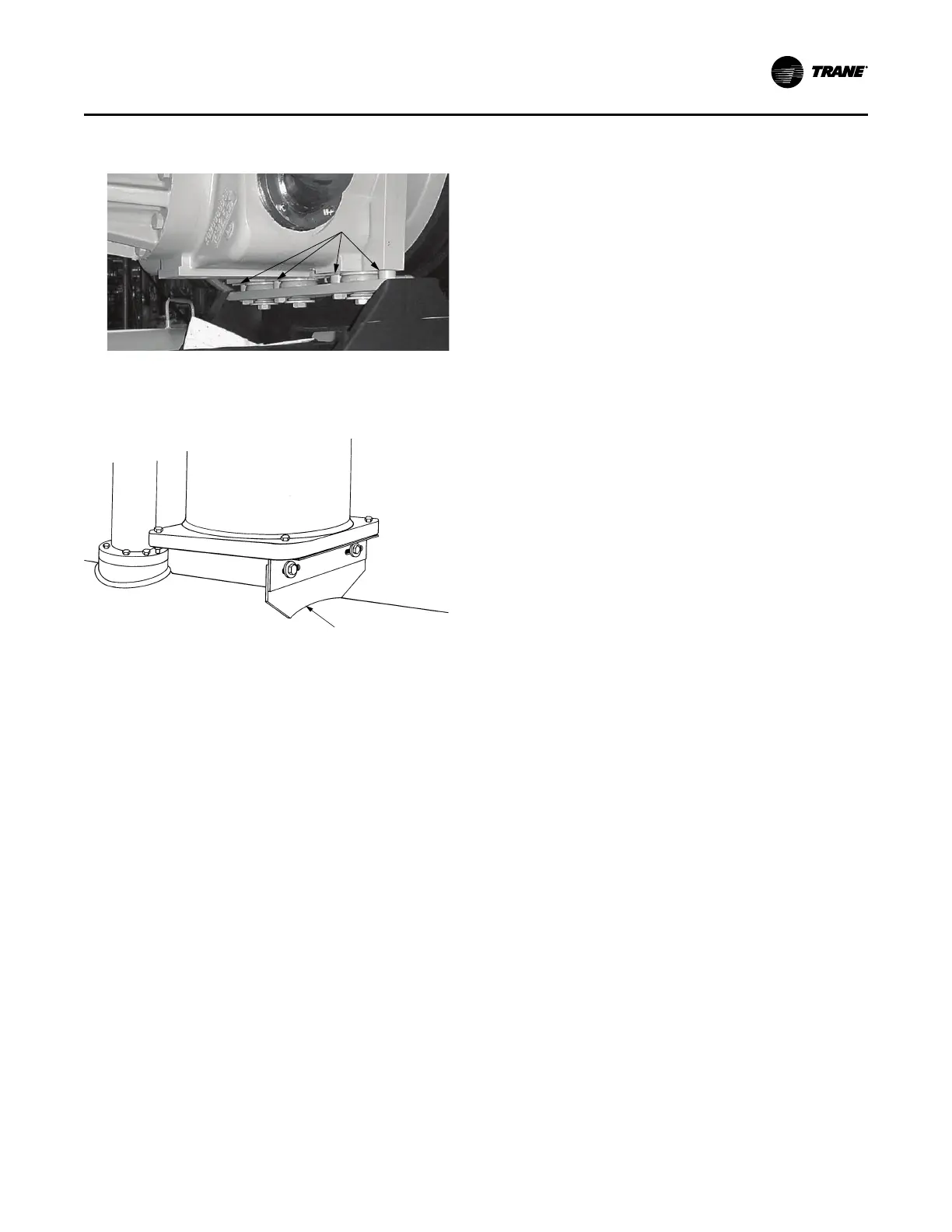

Figure 10. Compressor shipping spacers C, D, E

family (discharge side)

Compressor

Housing

Remove (4)

Puck-Type

Spacers

10. Remove the shipping brackets from the bottom sides of

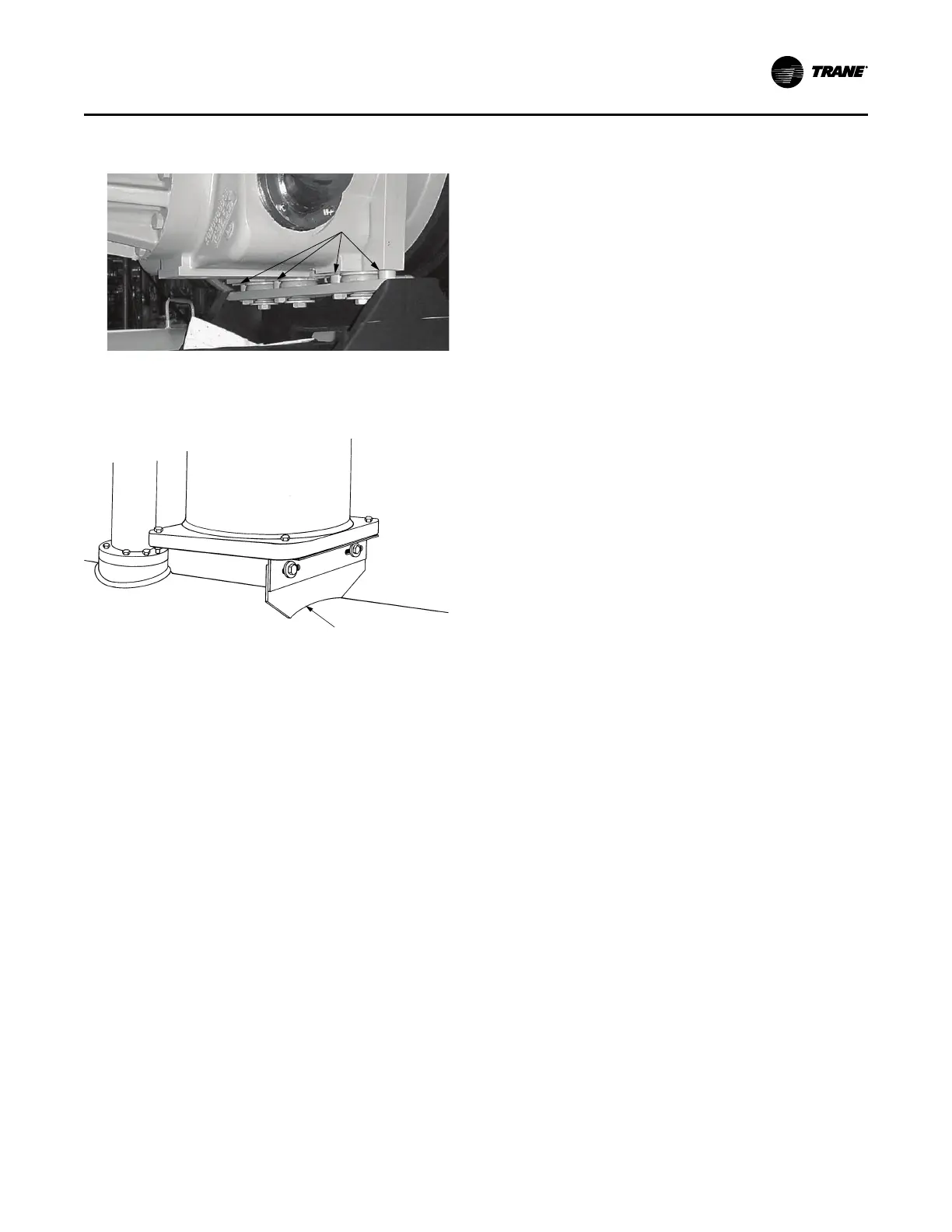

the oil separator(s). See Figure 11, p. 23.

Figure 11. Oil separator shipping bracket

Notes:

• Once shipping bracket(s) is removed, the oil

separator is only supported by the discharge

line.

• Failure to remove oil separator shipping

brackets could result in excessive noise.

Unit Leveling

Note: The electrical panel side of the unit is designated as

the “front” of the unit.

1. Check unit level end-to-end by placing a level on the

top surface of the evaporator shell.

2. If there is insufficient surface available on the top of

evaporator shell, attach a magnetic level to bottom of

shell to level the unit. Unit should be level to within 1/4

inch (6.35 mm) over its length.

3. Place the level on the evaporator shell tube sheet

support to check side-to-side (front-to-back) level.

Adjust to within 1/4 inch (6.35 mm) of level front-to-

back.

Note: The evaporator MUST be level for optimum heat

transfer and unit performance.

4. Use full-length shims to level the unit.

Alternate Moving Method

If it is not possible to rig from above as shown in , the unit

may also be moved by jacking each end high enough to

move an equipment dolly under each tube sheet support.

Once securely mounted on the dollies, the unit may be

rolled into position.

Alternate Moving Method

If it is not possible to rig from above as shown in , the unit

may also be moved by jacking each end high enough to

move an equipment dolly under each tube sheet support.

Once securely mounted on the dollies, the unit may be

rolled into position.

Isolation Pads

Notes:

• The elastomeric pads shipped (as standard)

are adequate for most installations. For

additional details on isolation practices consult

an acoustical engineer for sound-sensitive

installations.

• Durometer values for isolator pads are a

measure of resilience. See the following figure.

Installation Mechanical

Loading...

Loading...