22

RTHD-SVX01L-EN

WARNING

Shipping Mounts!

Failure to follow below instructions could result in

death or serious injury or equipment damage.

• Do not use the threaded holes in the compressor

to lift or assist in lifting the unit. They are not intended

for that purpose and could create a dangerous

situation.

• Do not remove the wood mounts until the unit is in

its final location.

NOTICE

Equipment Damage!

Failure to follow instructions below could result in

equipment damage.

• Never use a forklift to move the unit. The skid is

not designed to support the unit at any one

point and using a forklift to move the equipment

may cause unit damage.

• Always position the lifting beam so that cables

do not contact the unit.

Note: If absolutely necessary, the chiller can be pushed or

pulled across a smooth surface if it is bolted to wood

shipping mounts.

1. See Table 2, p. 15 or Table 3, p. 15 for unit shipping

weights.

Note: Weights are typical for units with R-134a or R-513A

charge.

2. When unit is at its final location, remove shipping bolts

that secure unit to wood base mounts.

3. Install clevis connectors in lifting holes provided on the

unit. Attach lifting chains or cables to clevis connectors

as shown in Figure 7, p. 20. Each cable alone must be

strong enough to lift the chiller.

4. Attach cables to lifting beam as shown in Figure 7, p.

20. See Table 5, p. 20 for rigging dimensions. The

lifting beam crossbar must be positioned so the lifting

cables do not contact unit piping or electrical panel

enclosure.

5. Connect an anti-rotation strap or cable loosely between

the lifting beam and the threaded coupling or eyelet

provided at the top of the compressor. Use an eyebolt

or clevis to secure the strap at the coupling or eyelet.

Important: The anti-rotation strap is not a lifting chain, but

a safety device to ensure that the unit cannot

tilt during lifting.

6. Lift from above, or jack the unit per “Alternate Moving

Method,” p. 23. Remove the base mounts.

7. During final positioning of the unit, place the isolation

pads under the evaporator and condenser tube sheet

supports as shown in Figure 12, p. 24. See “Isolation

Pads,” p. 23 for information on isolation pads.

8. Level the unit as described in “Unit Leveling,” p. 23.

9. The unit is shipped with spacers on the compressor

mount that protect isolation pads during shipping and

handling. Before the unit is operated, remove the

spacers as indicated to prevent excessive noise.

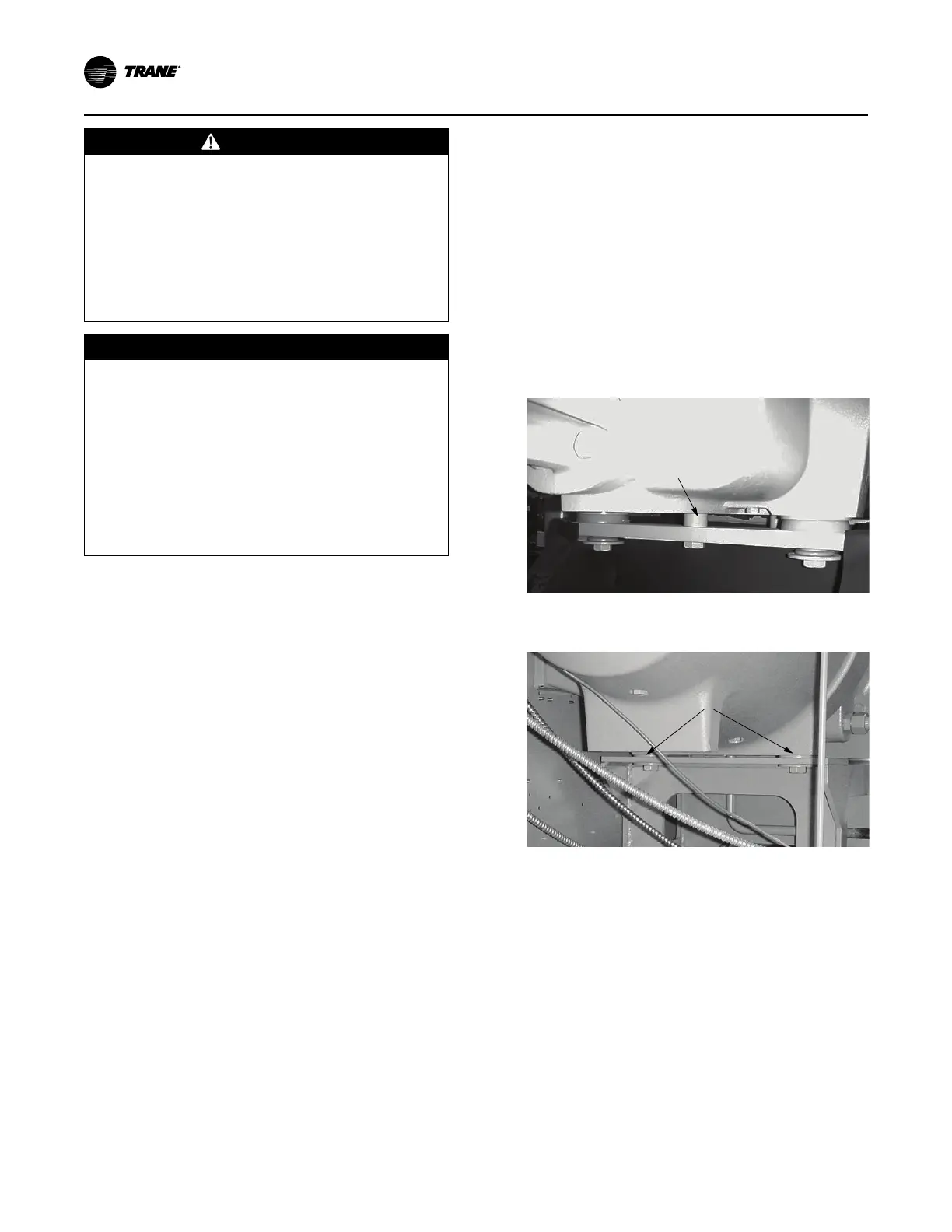

• B Family Compressors:

– Remove qty 1 puck-type spacer under discharge

side of compressor (see Figure 8, p. 22.

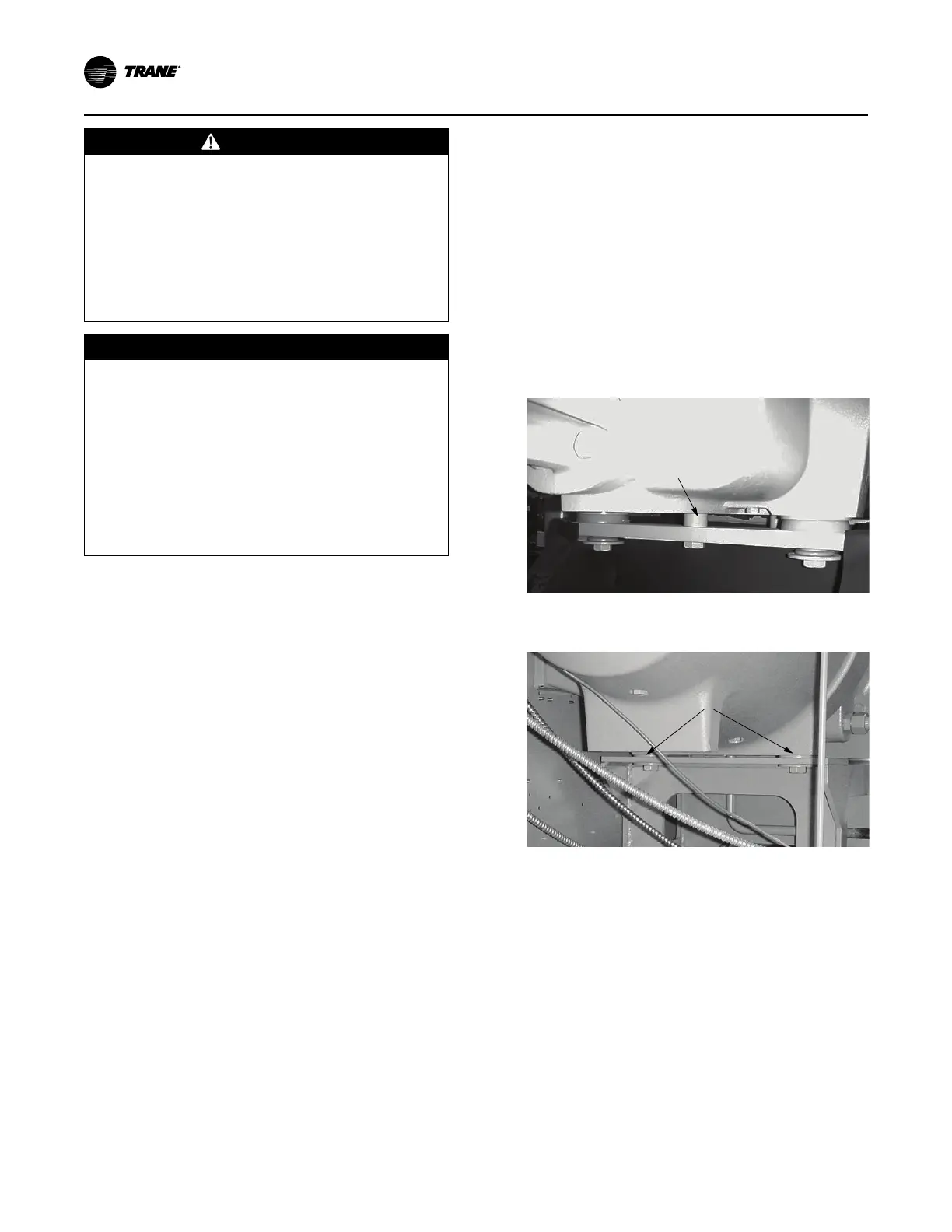

– Remove qty 2 flat washer spacers under suction

side of compressor (see Figure 9, p. 22).

Note: Suction side of compressor WILL float.

Figure 8. Compressor shipping spacers B family

(discharge side)

Compressor Housing

Remove (1)

Puck-type Spacer

Figure 9. Compressor shipping spacers B family

(suction side)

Compressor Housing

Remove (2)

Flat Water Spacers

• C, D, E Family Compressors:

– Remove (4) puck-type spacer under discharge side

of compressor (see Figure 10, p. 23).

Installation Mechanical

Loading...

Loading...