RTHD-SVX01L-EN

33

NOTICE

Equipment Damage!

Failure to comply with specifications may result in

capacity reduction, unit damage and/or relief valve

damage.

Do NOT exceed vent piping code specifications!

Relief valve discharge setpoints and capacities rates are

given in . Once the relief valve has opened, it will re-close

when pressure is reduced to a safe level.

Note: Once opened, relief valves may have tendency to

leak and must be replaced.

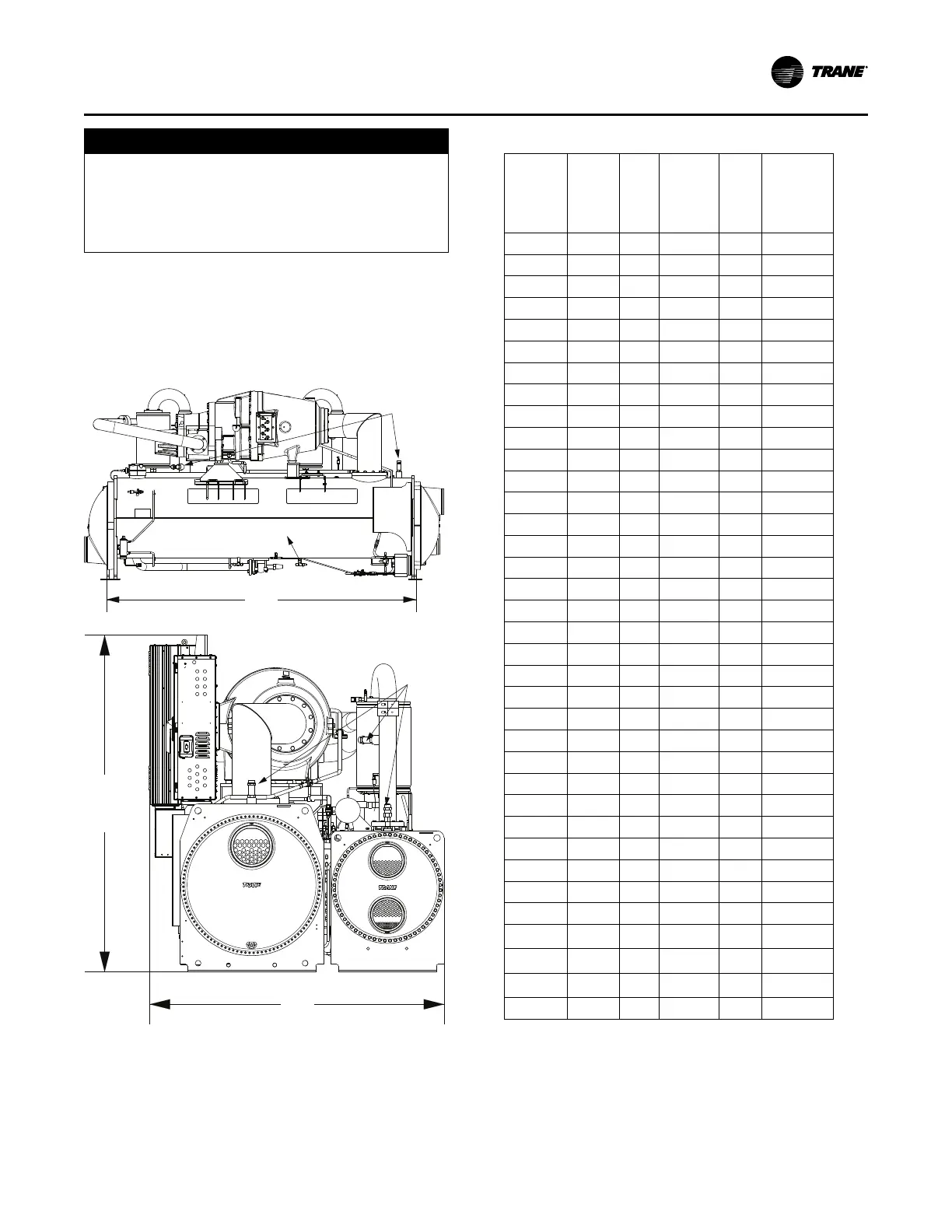

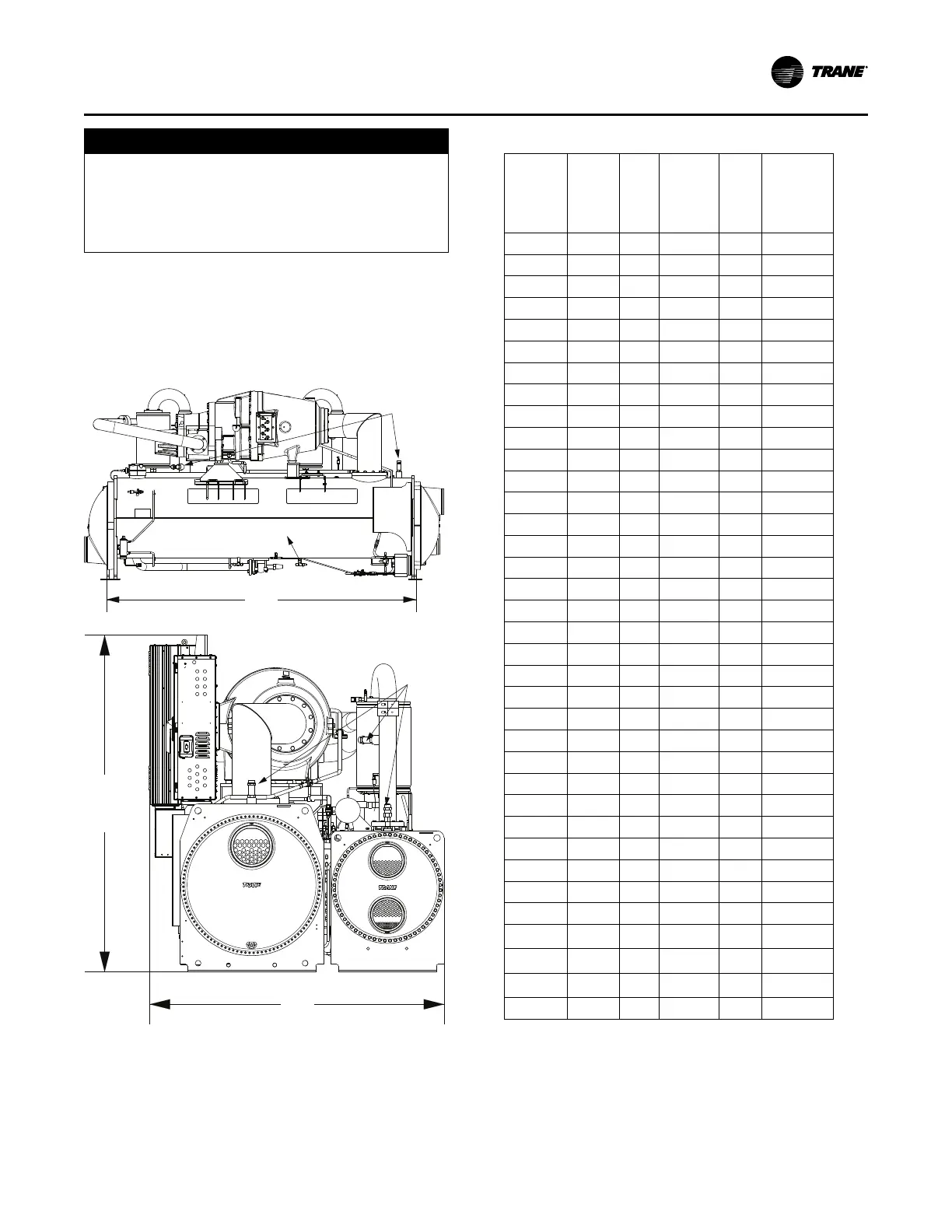

Figure 17. Relief valve location

Relief

Valves

Evaporator Condenser

W

H

Relief Valves

Evaporator

L

Pressure relief valve discharge capacities will vary with

shell diameter and length and also compressor

displacement. Discharge venting capacity should be

calculated as required by ASHRAE Standard 15-94. Do not

adjust relief valve setting in the field.

Table 6. Pressure relief valve data

Valve

Location -

Size

Dis-

charge

Setpoint

(psi)

Num-

ber of

Valves

Rated

Capacity

per Relief

Valve (lba/

min)

Field

Conn

Pipe

Size

(NPT)

Factory

Shell Side

Conn (in)

Evap - B1

200 1 48 1 1-5/16 - 12

Evap - B2

200 1 48 1 1-5/16 - 12

Evap - B3

200 1 48 1 1-5/16 - 12

Evap - C1

200 1 48 1 1-5/16 - 12

Evap - C2

200 1 48 1 1-5/16 - 12

Evap - D1

200 1 48 1 1-5/16 - 12

Evap - D2

200 1 48 1 1-5/16 - 12

Evap - D3

200 1 48 1 1-5/16 - 12

Evap - D4

200 1 48 1 1-5/16 - 12

Evap - D5

200 1 48 1 1-5/16 - 12

Evap - D6

200 1 48 1 1-5/16 - 12

Evap - E1

200 1 48 1 1-5/16 - 12

Evap - F1

200 1 48 1 1-5/16 - 12

Evap - F2

200 1 48 1 1-5/16 - 12

Evap - G1

200 1 78.8 1-1/4 1-5/8 - 12

Evap - G2

200 1 78.8 1-1/4 1-5/8 - 12

Evap - G3

200 1 78.8 1-1/4 1-5/8 - 12

Cond - B1 200 2 48 1 1-5/16 - 12

Cond - B2 200 2 48 1 1-5/16 - 12

Cond - D1 200 2 48 1 1-5/16 - 12

Cond - D2 200 2 48 1 1-5/16 - 12

Cond - E1 200 2 48 1 1-5/16 - 12

Cond - E2 200 2 48 1 1-5/16 - 12

Cond - E3 200 2 48 1 1-5/16 - 12

Cond - E4 200 2 48 1 1-5/16 - 12

Cond - E5 200 2 48 1 1-5/16 - 12

Cond - F1 200 2 48 1 1-5/16 - 12

Cond - F2 200 2 48 1 1-5/16 - 12

Cond - F3 200 2 48 1 1-5/16 - 12

Cond - G1 200 2 48 1 1-5/16 - 12

Cond - G2 200 2 48 1 1-5/16 - 12

Cond - G3 200 2 48 1 1-5/16 - 12

Comp - B1/

B2

(a)

200 2 78.8 1-1/4 1-5/8 - 12

Comp - C1/

C2

(a)

200 3 78.8 1-1/4 1-5/8 - 12

Comp - D1/

D2/D3

(a)

200 3 78.8 1-1/4 1-5/8 - 12

Comp - E3

(a)

200 3 78.8 1-1/4 1-5/8 - 12

(a)

Only used with isolation valve option

Thermal Insulation

All Optimus™ units are available with optional factory

installed thermal insulation. If the unit is not factory

insulated, install insulation over the areas shaded in Figure

Installation Mechanical

Loading...

Loading...