2) During installation,be careful not to damage

the lips,and assure that it is pushed in

parallel to the shaft or hole.

3) When oil seals are installed,there should be

no turnover of the lips nor dislocation of the

springs.

4) When a multi-lip seal is installed, the

grooves between lips should be filed

with grease, not adhesive.

(3) O-rings

1) O-rings should be coated with grease

before installing.

2) Installed O-rings should have no slack or

twist.

3) Installed O-rings should maintain proper

air tightness.

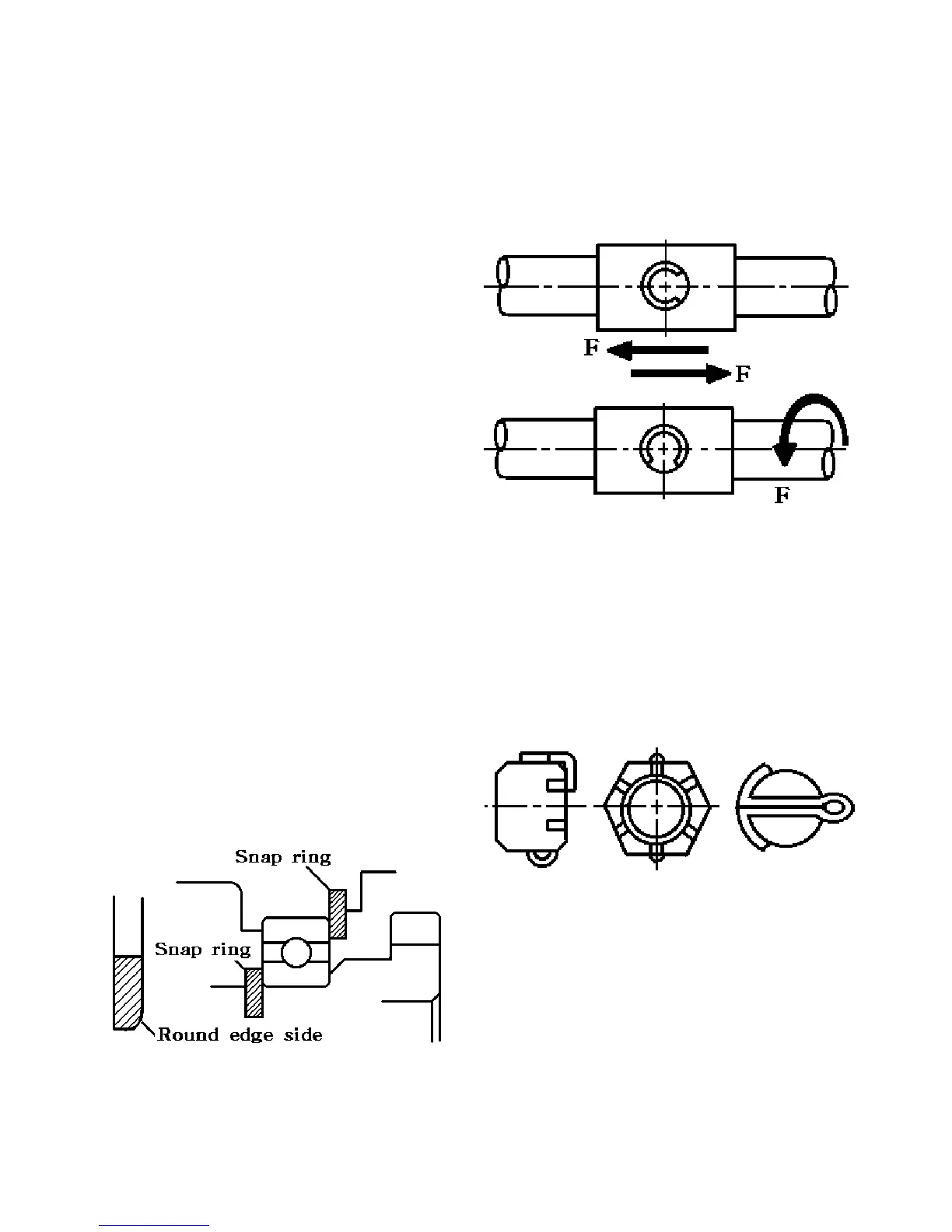

(4) Snap rings

1) Snap ring installers should be designed so

as not to permanently deform the snap

rings.

2) Installed snap rings should be seated

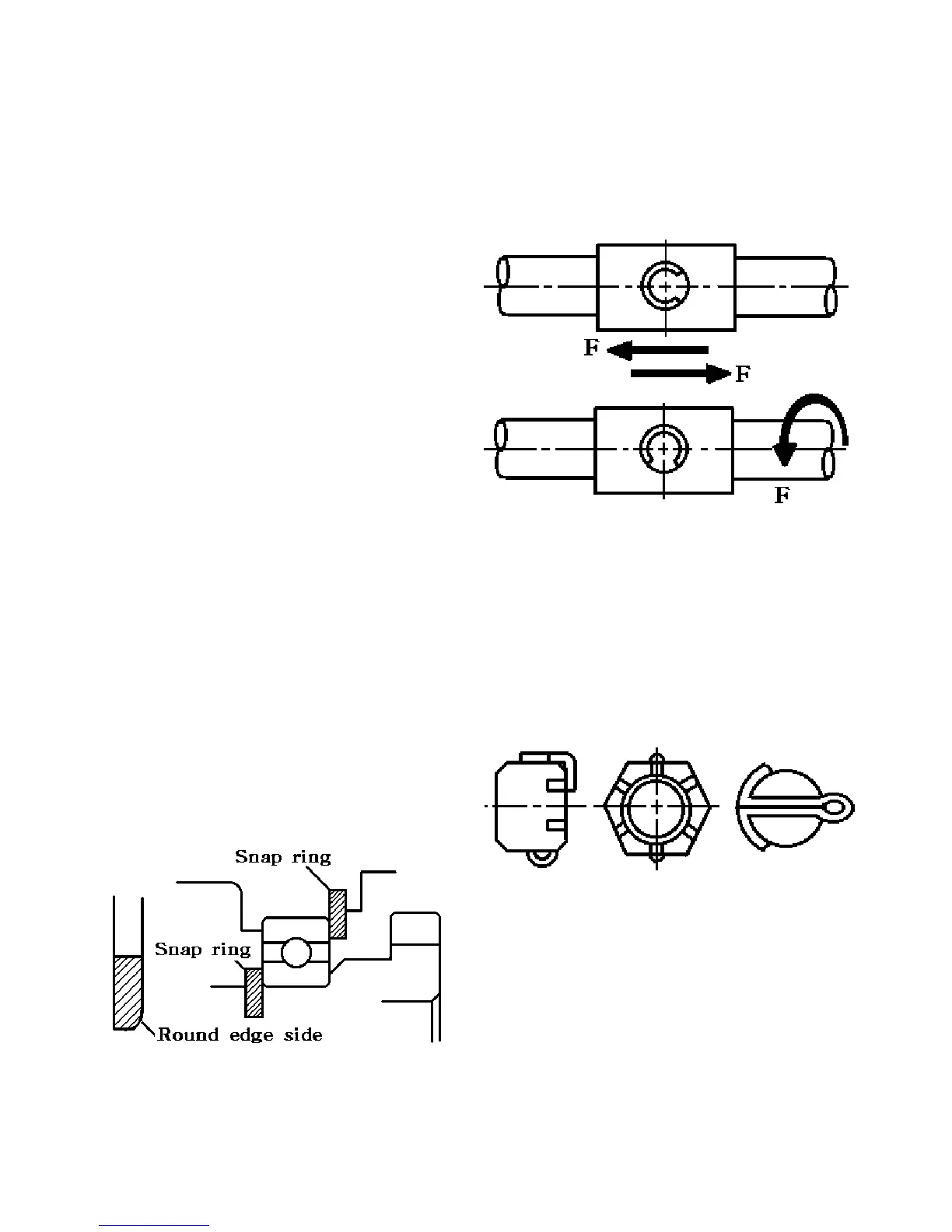

(5) Spring(roll) pins

1) Spring pins should be driven in properly as tightly.

2) Spring pins should be installed so that their

seams should face the direction from which the

load is applied.

3) The roll pins installed in the transmission or

other parts where much force is applied

should be retained with the wire.

Fig.2-2

3) Be careful not to overload the snap ring to

the extent that it is permanently deformed.

4) How to install the snap ring:

When installing a snap ring,install it as

shown in the figure with its round edge side

turned toward the part to be retained.

This round edge is formed when the snap

ring is pressed out.

Fig.2-1

(6) Cotter pins

When installed, cotter pins should be bent

securely at the ends as shown in the figure

Fig.2-3

(7) Bolts and nuts

1) Special bolts are installed at several

locations ,so be sure not to interchange them

other bolts.

2) Bolts and nuts should be tightened to their

specified torque wrench.

3) When locking the bolts or nuts with wire or a

lock washer,

2-2

Loading...

Loading...