3.HYDROSTATIC TRANSMISSION

DISASSEMBLY

4. Remove gasket from pump assembly.

Back plate Disassembly:

NOTE:Pump and motor valve plates are

IMPORTANT: The pump body and motor

body are aluminum and can be easily

damaged by steel tools.Be careful to not

damage machined surfaces.Do not use

screw driver or other sharp objects to pry

pump or motor body from back plate.

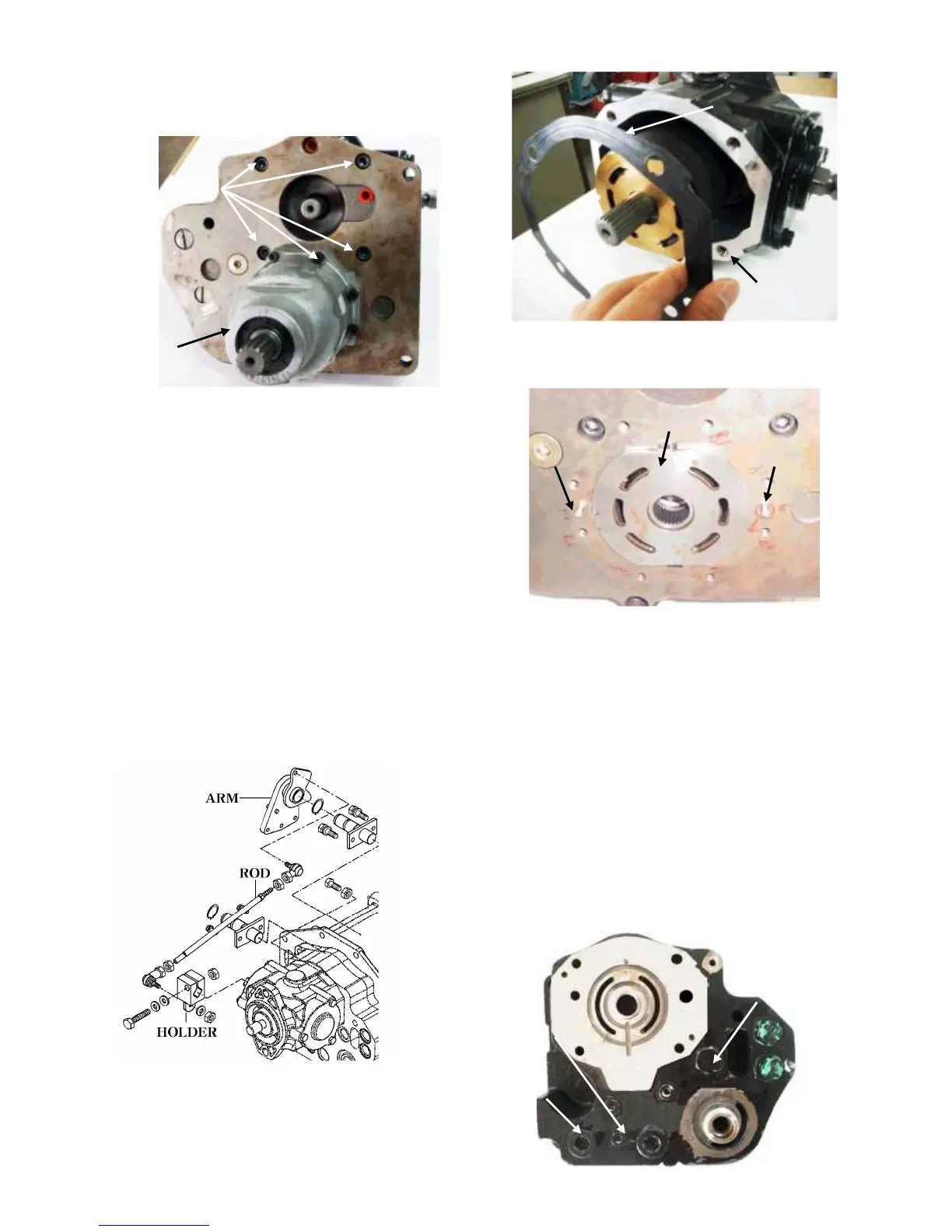

1.Remove eight socket head screws Securing

the hydrostatic motor to the back plate.tap

of the motor housing with a plastic mallet

to loosen it from the valve plate.Keep the

assembly level or tip output end down to

Cap screws

Hydrostatic

motor

Gasket

Hydrostatic

pump

Spring pin

Dowel pin

Motor valve plate

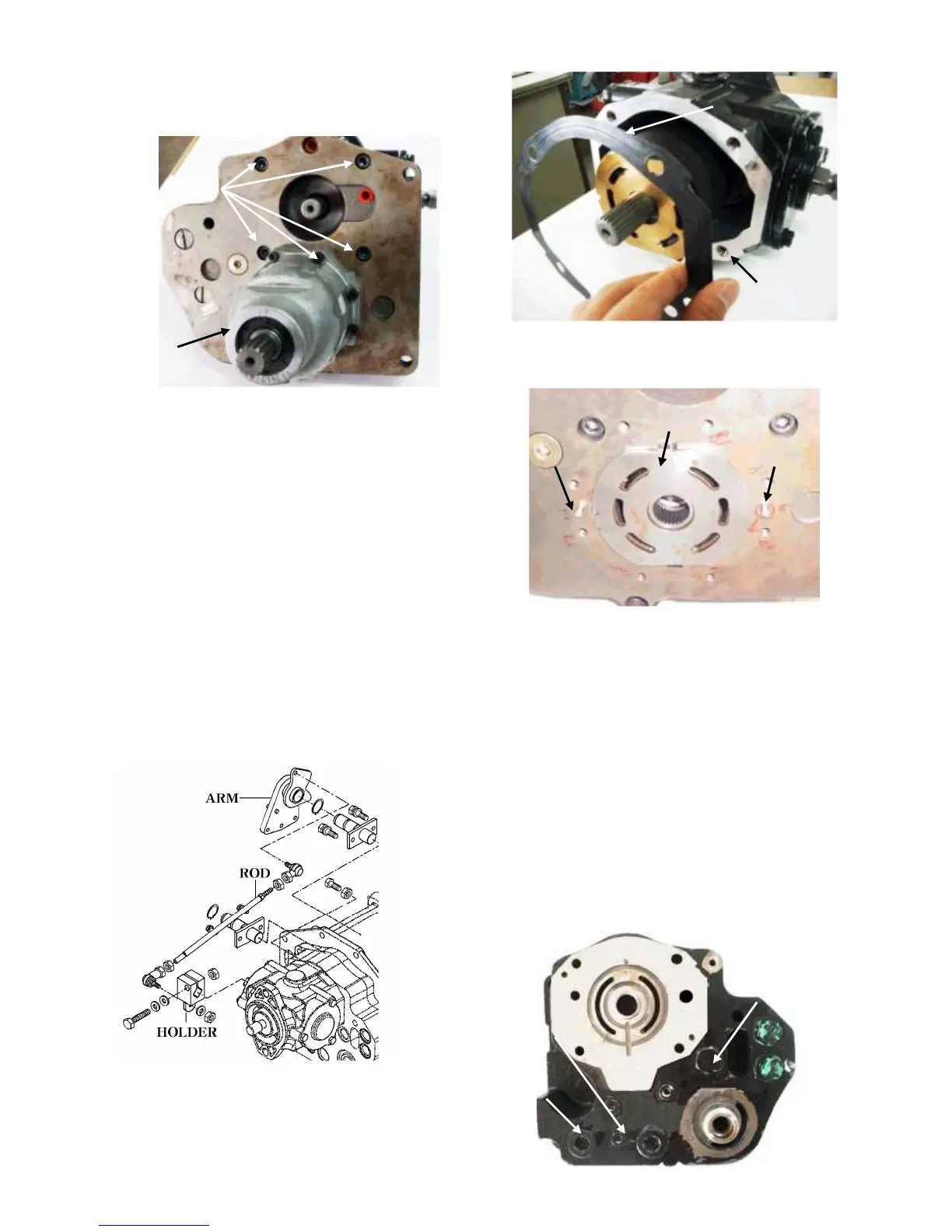

3.Remove cap screw and nut.Remove

holder and arm as an assembly.

NOTE:Pump and motor valve plates are

very similar in appearance,but are not

interchangeable.Note shape of valve

plates when removing.Valve plates are

not fastened to back plate,but may

adhere slightly because of oil between

the machined surfaces.

5.Remove valve plates from the back plate.

6.Remove two dowel pins.

NOTE:Unless spring pin used to locate

valve plate is damaged or loose,do not

remove.If replacement is necessary,

Use care not to scratch the machined

surfaces of the back plate.

4-24

assembly level or tip output end down to

keep the rotating assembly from sliding off

of shaft.Pull the motor housing,shaft,and

rotating assembly away from back plate.

2.Remove the four socket head cap screws

securing the pump to the back late.

Remove pump.

Reverse

Relief valve

Forward

Relief valve

Charge pressure

Relief valve

Loading...

Loading...