3. INSPECTION OF EACH PART

1) Inspection of the cleaner body

(1) Check the cleaner exterior for cracks,

deformation,or damage and repair or replace

if necessary.

(2) Check each packing for fatigue or damage

and replace if necessary.

2) Inspection of rubber hoses

Check the rubber hoses for fatigue or damage

and replace if necessary.

3) Inspection of the paper element to check

Note:

Especially note the glue portions of the paper and

metal parts.

4. CLEANING THE AIR CLEANER

Clean the air cleaner after 100 hours of operation or

less depending on conditions in the following manner.

1) When the air cleaner is cleaned or the element is

replaced,dust accumulated inside the air cleaner body

should be removed with a cloth.As inhaled dust causes

engine wear,remove a dust accumulated inside the inlet

pipe,the rubber hose which connects in the inlet pipe

and the air cleaner,the inlet manifold,and inlet port.

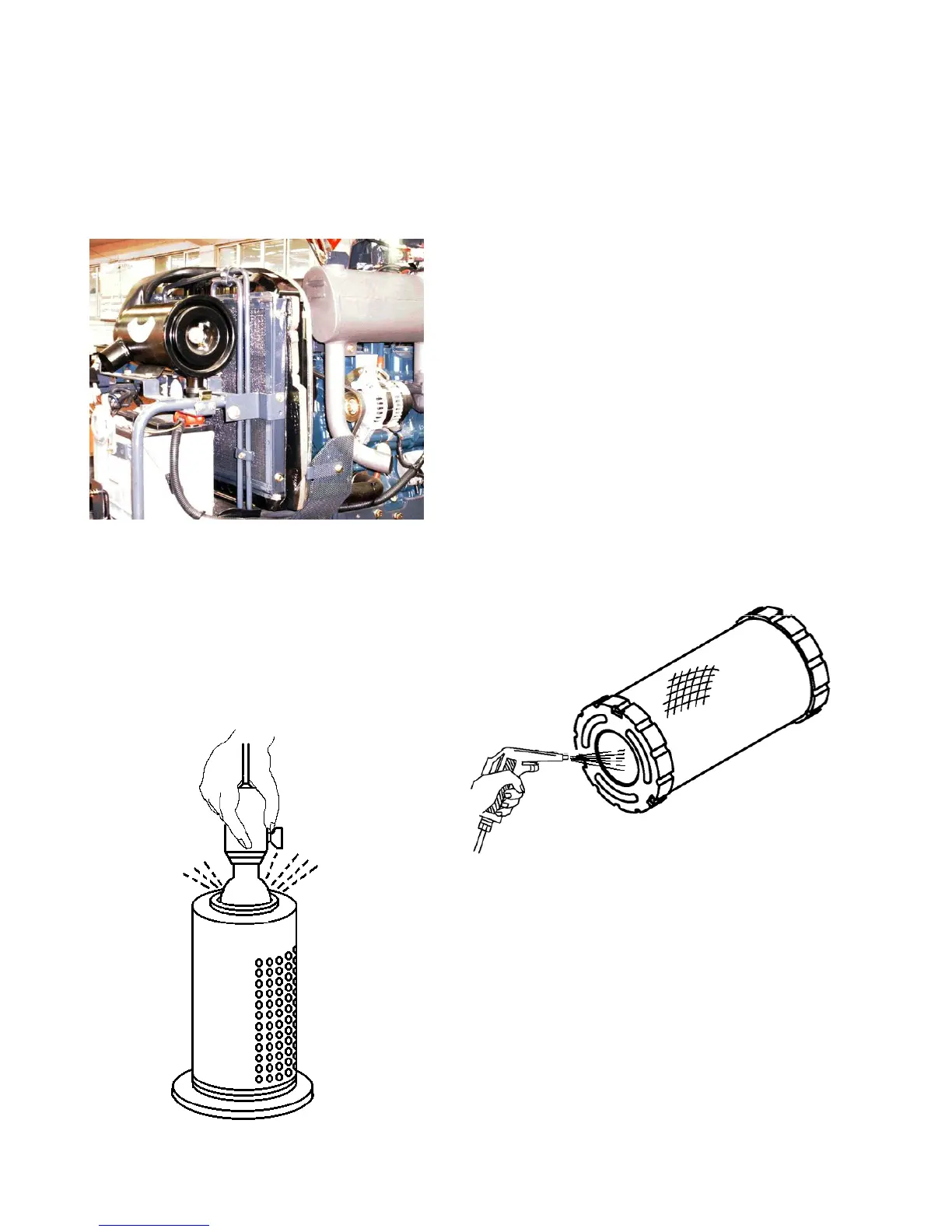

(1)When accumulated dust is dry.

-When removing the dust in the element,hold the

element by a hand and pat the side wall with other

hand. Never hit the element against a stone or a

concrete wall because that might cause its side wall

to peel off.

-apply compressed air from inside of the element to

blow dust off while turning the element by hand.

3) Inspection of the paper element to check

the element for damage,Dry it sufficiently

after washing and put an electric bulb in to

the element and look for damage.

FIG.3-12 Element check

Note:

The compressed air to be applied should not

have a pressure of more than 7㎏/㎠(99.6psi)

Maintain sufficient distance between the air gun

and the element.

(2)When accumulated dust is oily.

-Use a solution of TC 101 element detergent

or the quality household neutral detergent.

Leave the element in the solution for

approximately 30 minutes and then wash it by

dipping it in and out of the solution.

3-9

FIG.3-13 Element

Loading...

Loading...