NOTE: If neutral adjustment cap screw is

loosened,neutral adjustment procedure must be

performed.see “HYDRAULIC PEDAL AND

NEUTRAL ADJUSTMENT”

15.Inspect pivot and cam followers on neutral

return lever for smooth operation.Replace

parts as needed.

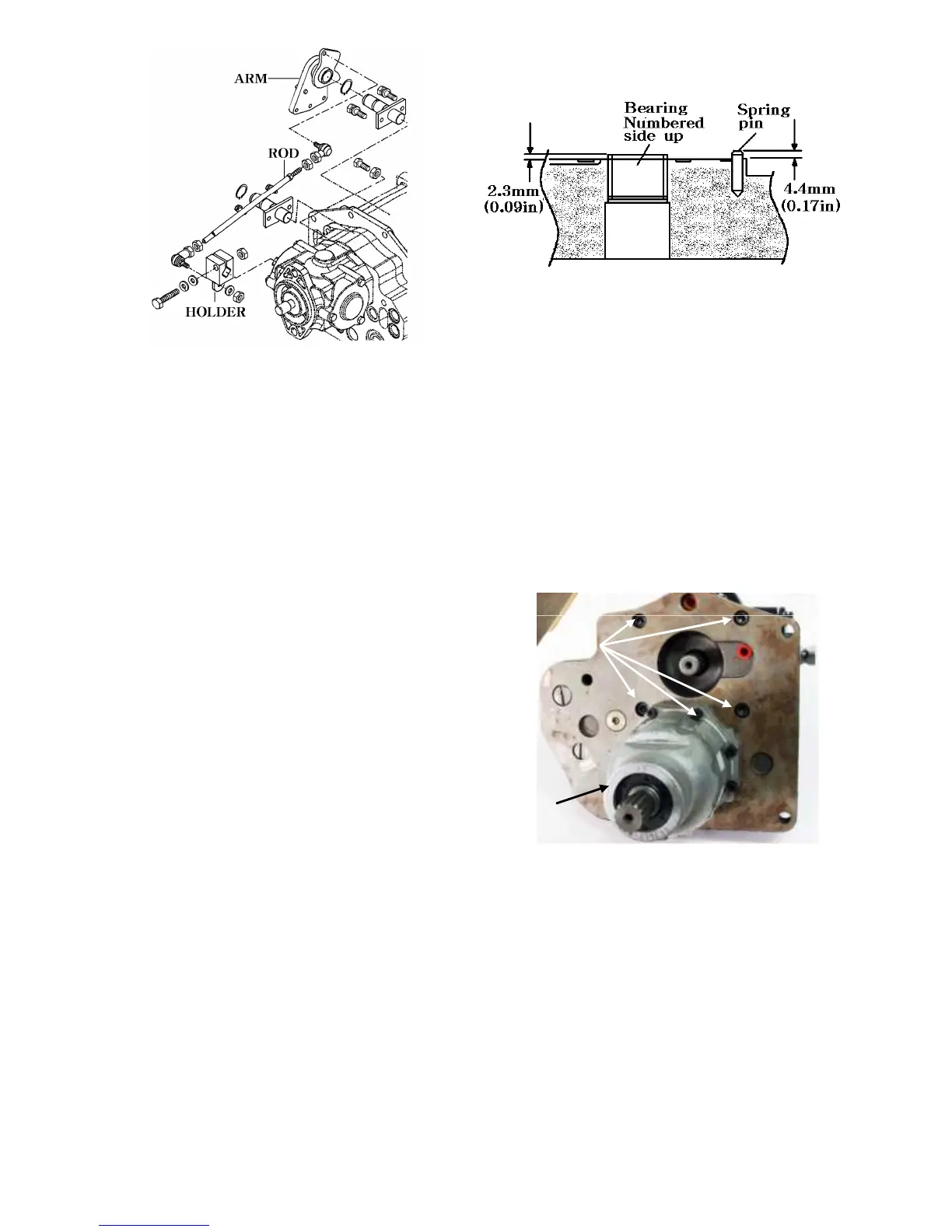

Back plate Assembly:

1.On motor side of the back plate,install the

filter bypass valve.Tighten to 16-20N.m

8. If the bearings were removed from the back

plate,press new ones into position using a

suitable bearing driver.The numbers on the

bearing should face the outside of the back

plate.press the bearing in until 2.3±0.2 mm

(0.09in ±0.010in) of the race remains

above the surface of the back plate.

9. If removed,install the spring pin that is used

to position the valve plate.Allow the pin to

protrude from the back plate approximately

4.4mm(0.17in).

4. HYDRAULIC PUMP

DISASSEMBLY

NOTE:Cooler bypass valve spring and charge

relief valve spring could accidentally be mixed

up.Charge relief valve spring is thicker.

2.Install the cooler bypass valve.Tighten to

28-33 N.M(21-24 lb-ft).

IMPORTANT: Old O-rings,gaskets and seals

will leak.Always install new O-rings,

gaskets and seals during assembly.

3.Install new O-ring to plug.Install plug.

Tighten to 13-16N.m(115-142lb-in)

4.On pump side of back plate,install new

O-ring to the three plugs.Install plugs.

Tighten to 135-149N.m(100-110 lb-in).

5.Install forward and reverse relief valves in

ports marked at disassembly.Tighten to

135-149N.m(100-110lb-ft).

6. Install charge pressure relief valve.Tighten

to 37-41N.m(27-30lb-ft).

7.Install two dowel pins.

IMPORTANT: The pump body is aluminum

and can be easily damaged by steel tools.

Be careful to not damage machined surfaces.

Do not use screw driver or other sharp

objects to pry pump body from back plate.

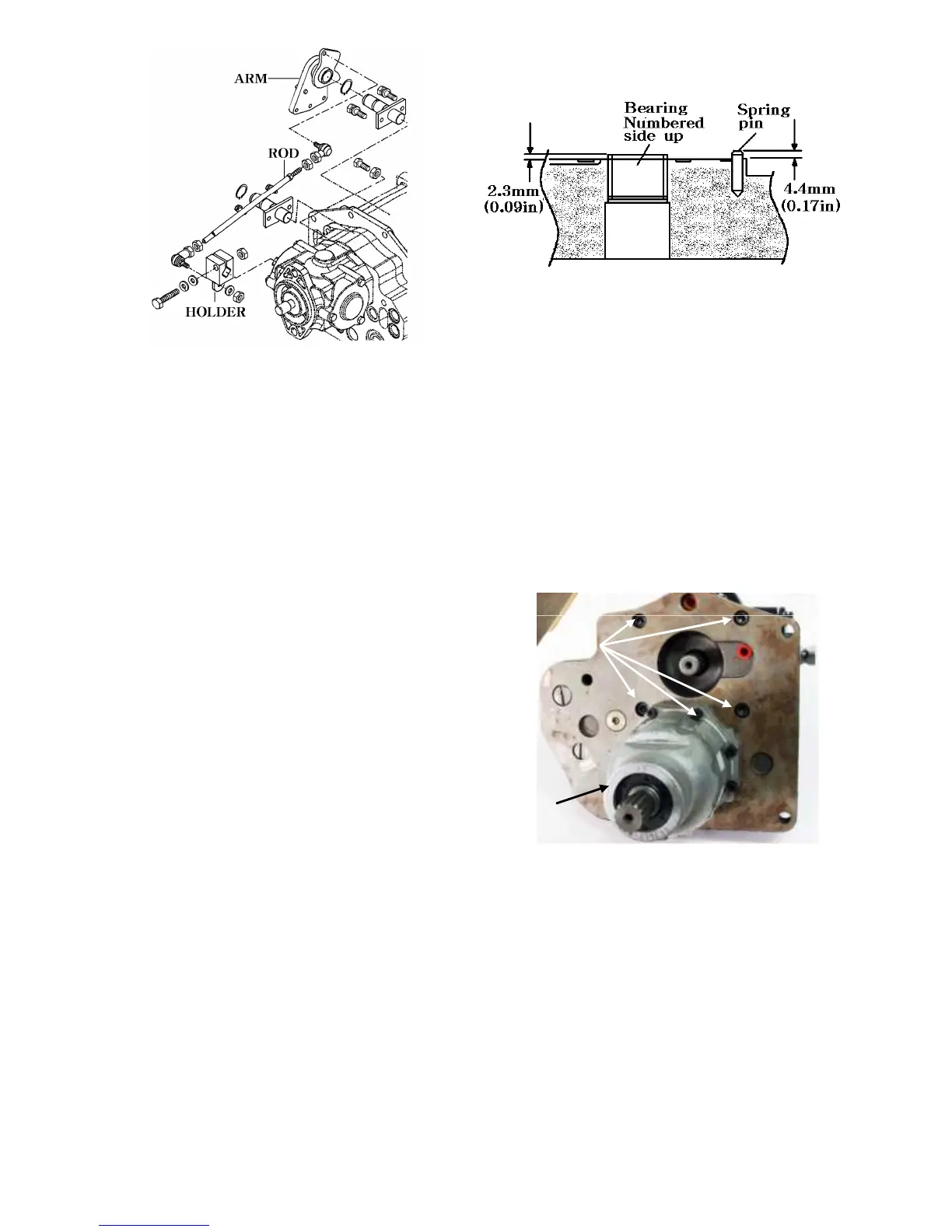

1.If not already done,remove four socket head

cap screws securing the pump to the back

plate .Tap pump body with a plastic mallet to

remove pump.

4-26

Cap screws

Hydrostatic

motor

Loading...

Loading...