4. WHEELBASE MODIFICATION

When it is necessary to modify a wheelbase it is important to under-

stand that this modification will greatly change the mass with respect to

the side rails. Caution should be used when modifying the side rails as

this will greatly affect their designed strength. This strength must be con

-

sidered from several different aspects. This type of modification should

be avoided, whenever possible. When modification to the side rails is

unavoidable, the following recommendations should be followed.

1) GENERAL CAUTIONS

a When modifying the wheelbase, do not extend or shorten the

wheelbase beyond the maximum or minimum specifications in the

wheelbase range set by Nissan Diesel Motor Co., Ltd.

b Side rails (including the detachment and addition of crossmembers),

propeller shaft, service brake lines, electrical lines must be modified

when modifying the wheelbase. All modifications must correspond

to the wheelbase configuration as listed in this Book.

2) CUTTING POINT

Cut the side rails where it is straight (not curved) and a low stress

point.

3) MATERIAL

a Use the same material for extending as the side rail.

Material See Section 3. 1) ; thickness should be 0.177 in (4.5 mm)

b When extending the frame, use a material with the same thickness

and shape as the location to be extended.

c Perform continuous welding so the part to be extended and the side

rail are completely connected, then, using a grinder, smooth and

finish the surface. Then fill with reinforcement material.

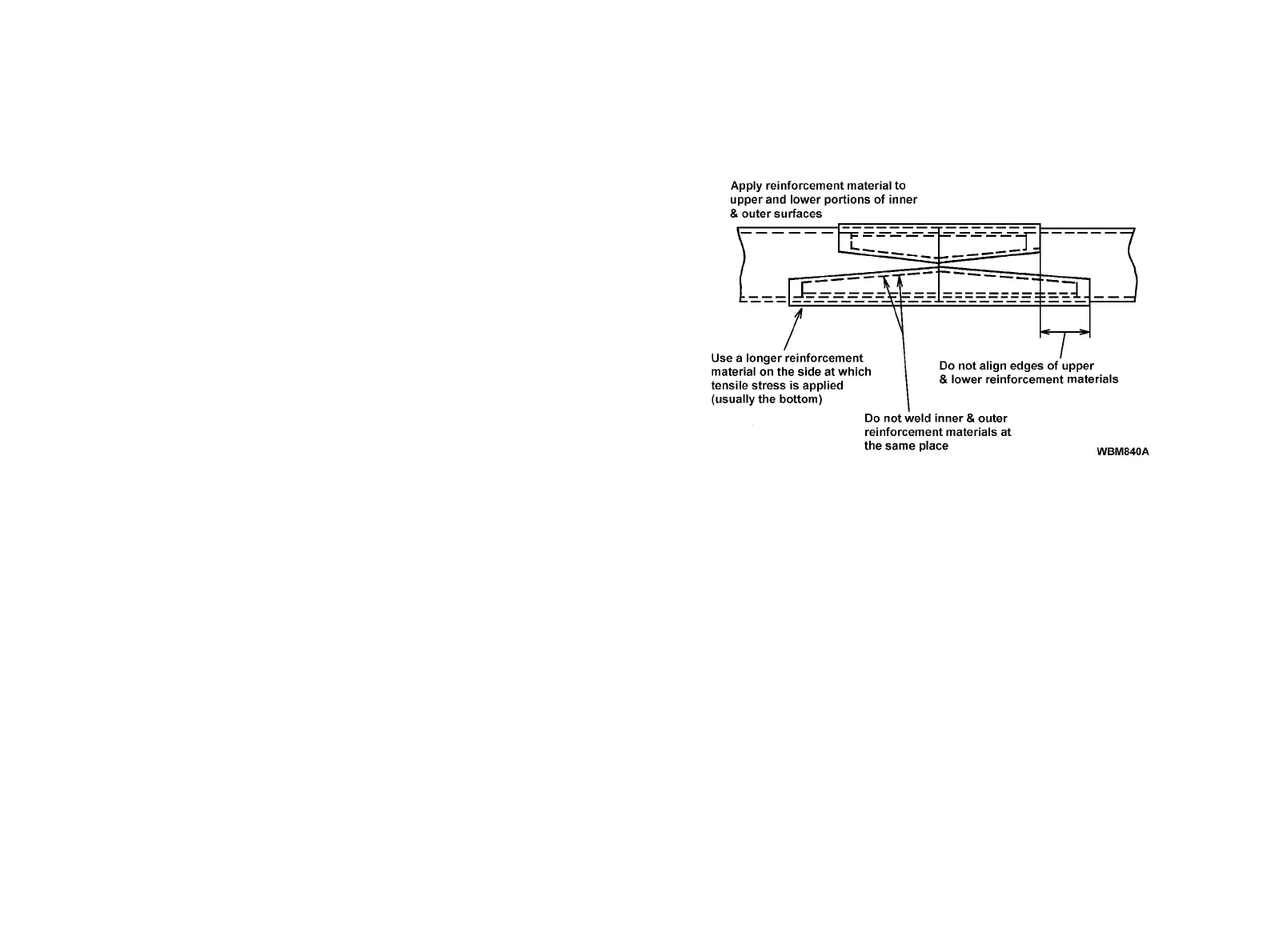

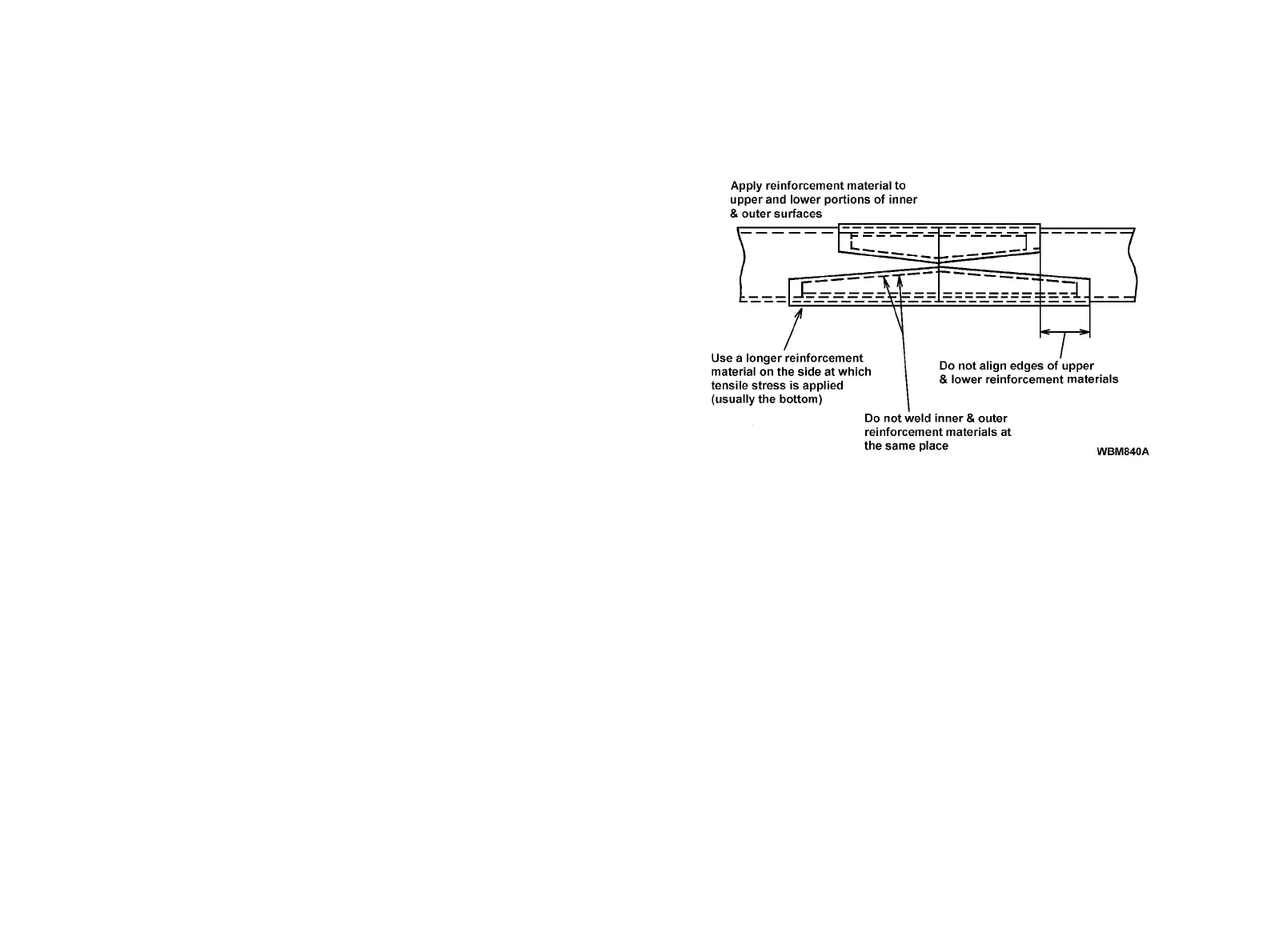

4) REINFORCEMENT MATERIALS FOR EXTENDED PARTS

The following diagram shows the shape of the reinforcement parts:

When welding to side rails, observe the precautions for side rail reinforce-

ment [section 3.].

C12

Loading...

Loading...