ENKOFORM VMK

Construcción

31

ENKOFORM VMK

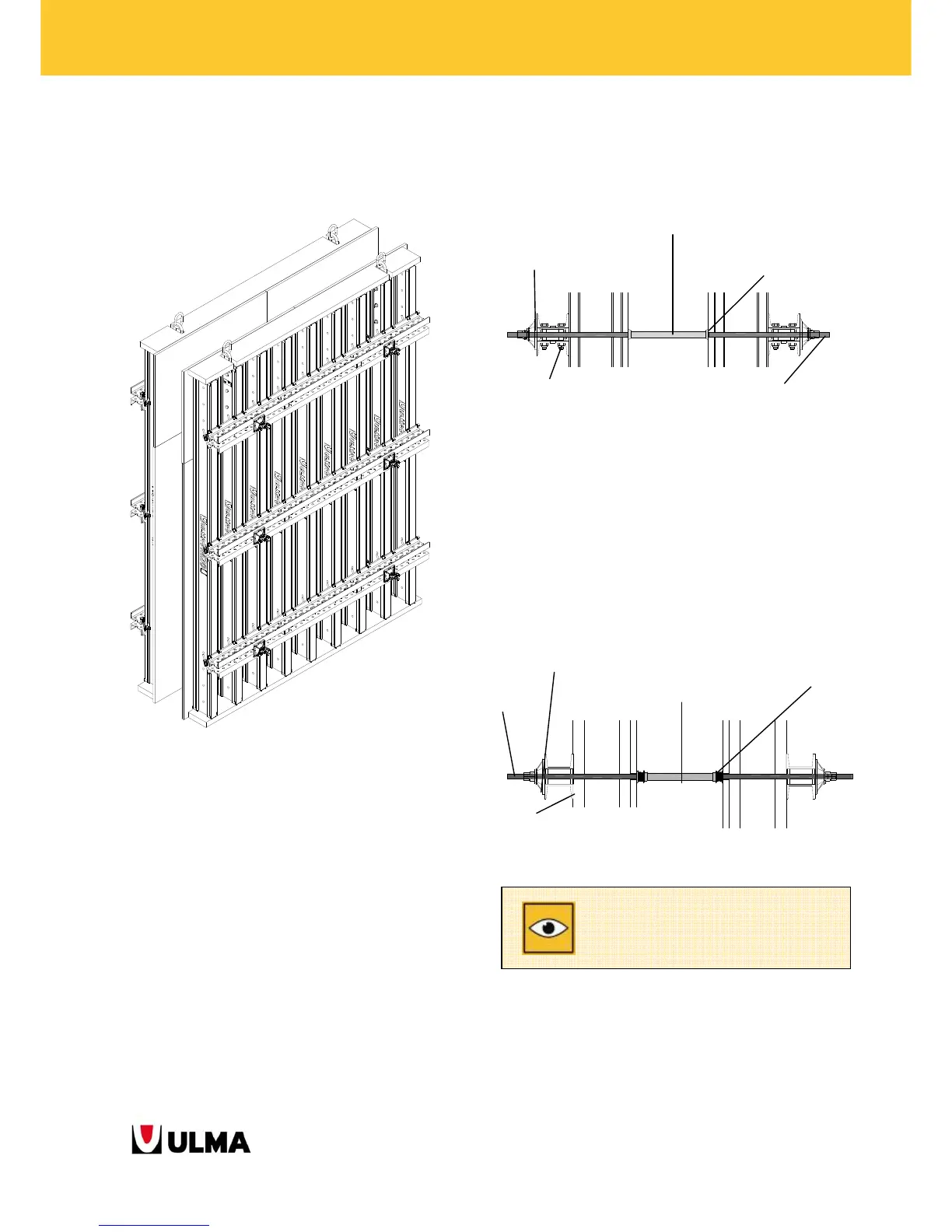

4.3. TIE ROD PLACING

The TIE RODS used in ENKOFORM VMK are mainly

TIE RODS 15.

2 PANELS with TIE RODS 15 and PLATE WASHER NUTS 15.

TIE RODS 15 will always be placed through the gap

between the two UPN profiles of the MK-120

WALERS and they are tied up by NUT WASHER

PLATES 15.

Between the PANELS of both sides, a SPACER TUBE

22 will be introduced, with CONES 22 on both sides.

Detail of the joint of two face-to-face-PANELS with SPACER TUBES

22 and CONES 22 between them.

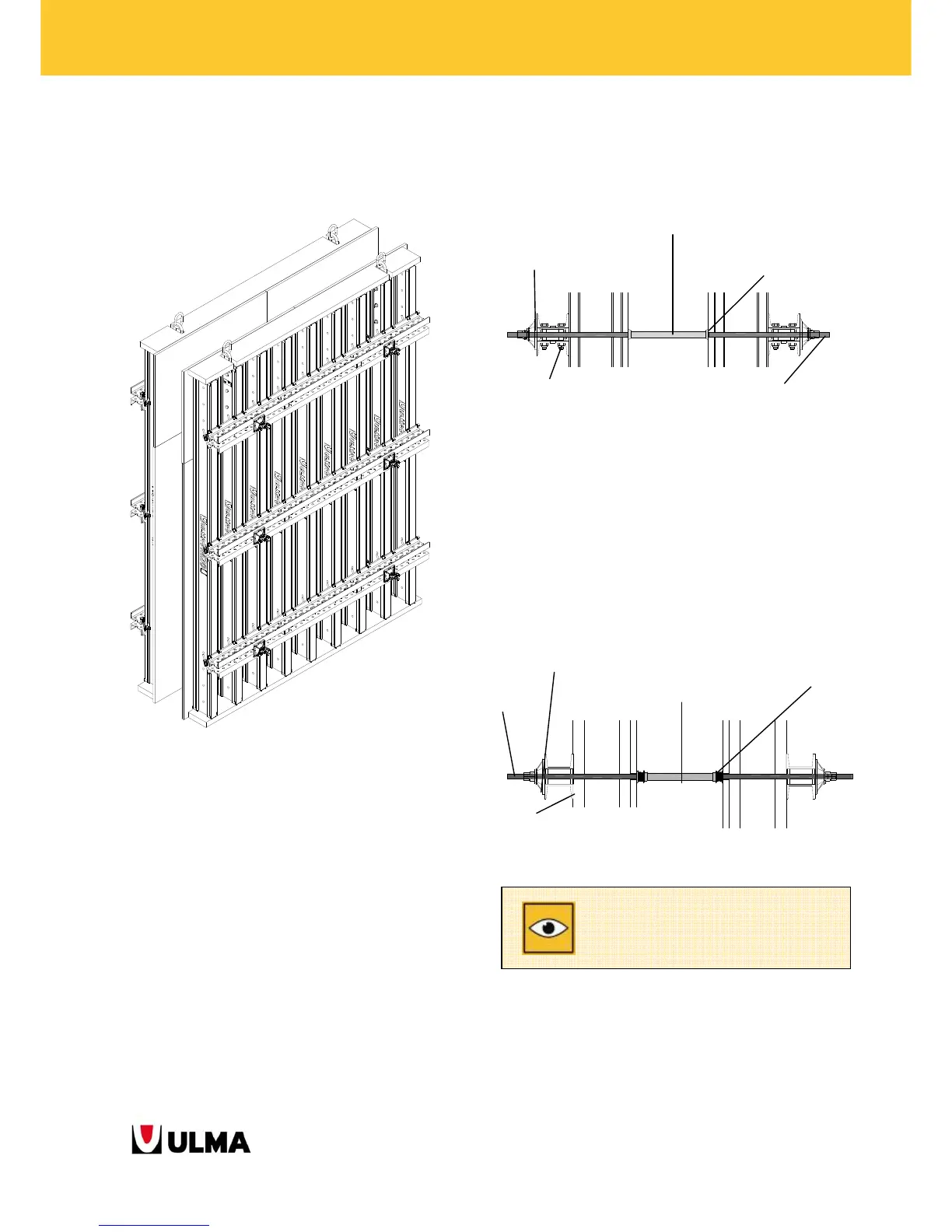

In case of liquid-hold-back, WATER STOP CAPS 26

will be used instead of CONES 22. The SPACER TUBE

22/26 will be placed between the 2 WATER STOP

CAPS 26. The PLUG 26 will be introduced in the

WATER STOP CAP 26 to avoid water leak.

This system lasts a liquid limit pressure of a 10 m

height.

Detail of the joint of two face-to-face-PANELS with SPACER TUBES

22/26 and WATER STOP CAPS.

Tie rod 15

Ti

Loading...

Loading...