9

BarcodeGuy.com® - UnionNet SP2100 User’s Guide

Having Problems? This section is for problems where the SP21002D times out while

trying to scan, not with problems with transferring the barcode data to a HID connected

bluetooth host. (for HID transmission problems, see Section 4.1):

● With the SP21002D directly above the barcode and perpendicular to it, press and

hold the Scan Button and center the green Aiming Line on the center of the

barcode. Slowly pull the SP2100 away while holding the Scan Button. As it gets

further away from the barcode, the SP2100 will eventually focus and decode the

barcode.

● With “glossy” codes decrease reflected light by varying the perpendicular angle

between the SP21002D and the barcode.

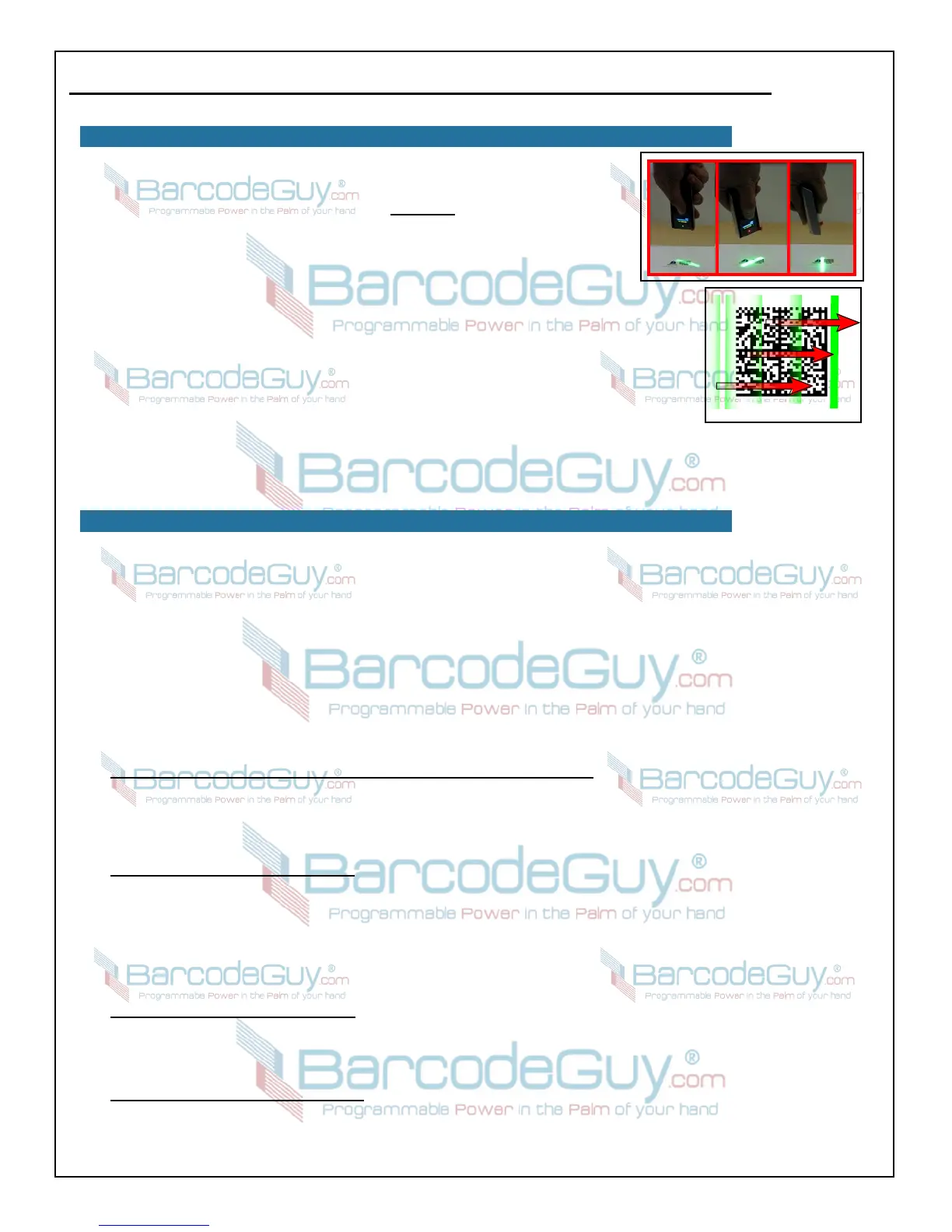

● On 2-Dimensional barcodes, the SP21002D will sometimes read quicker if you “raster” the

aiming light over the barcode (figure 2.10) . Just start at the non-printed end of one side of

the 2D barcode, press the Scan Button and drag the green Aiming Line from one side of the

barcode to the other.

As you start getting comfortable with your SP21002D, you’ll learn the focal point for the

different barcodes you use. Instinctively, like muscle memory, you’ll learn the proper focal length

figure 2.10

for the combination of the SP21002D and the particular densities of the barcodes you normally scan. If you have a

circumstance where the SP21002D will consistently not read a particular type of barcode, email us a picture of it and we’ll

give you a call. In most cases we can troubleshoot the problem right from the picture.

2.6 - Scanning Barcodes with the SP21002D, con’t

2.6.1 - Scan Barcodes from the screen of a PC, Tablet or Smart Phone with the SP21002D

One of the things an imager can do that a traditional laser line scanner can’t is read barcodes directly from the screen of any

device - Tablet, Smart Phone, Notebook or PC. To understand how to optimize for reading barcodes from a screen, it’s

important to have a slight understanding of the detail on how different barcode scanning technologies work. Laser line

scanners use a single light source laser diode operating in the light spectrum at 650 nm. The laser diode generates a red dot

similar to a laser pointer, and the line is generated by projecting the dot on to a vibrating mirror to give the optical illusion of

a line. The SP21002D is an imager; and the light generated by the multiple LED’s that make up the rectangular field of view

are generally of a lower frequency than the laser scanner. The big difference between the laser line scanner and the area

imager has to do with how the reflected light returning from the barcode is interpreted. In the imager, instead of just a few

elements tuned exactly to the reflected light expected from a 650 nm light source, the imager has a grid of sensors, much like

a monochrome camera with greater sensitivity. Because of this added sensitivity and the greater field of view, an imager can

work in environments where the laser scanner can’t compete. Specifically in reading 2D barcodes, reading reverse image

barcodes (where the dark elements are light) and reading barcodes displayed on a screen.

Reading barcodes from a screen have both barcode design and barcode scanning components. Here’s what to keep in mind:

● Design your on-screen barcodes 25% to 40% bigger than print barcodes - Because screens absorb light, the imager is

going to have to work harder to figure out that there’s a barcode in the field of view. Test the SP21002D with a printed

barcode of the same type, with the same number or the maximum number of encoded characters. As a rule of thumb,

make the on-screen barcode at least 25% bigger to start. Note that imager probably can read the same size barcode from

the screen as one printed, but you may find that it takes too much time to tune the distance and angle from the barcode to

make it easy for your users.

● Read on-screen barcodes at an angle - Although the preferred method of reading barcodes printed on non-glossy

surfaces is to hold the SP21002D directly over the barcode, the screen where the barcode is displayed is absorbing the

light projected by the imager. The screen also reflect light into the imager’s aperture from room light sources, diluting the

true reflected light from the barcode. The best way to compensate is to begin the scanning process at a 45 degree angle

from perpendicular. This will minimize both light absorbtion and reflection from the screen. with When you design the

barcode to be displayed on the screen, use a lower density. Technically, this mean that you should generate the barcode

with the smallest element is bigger than the same barcode that’s printed. Follow some simple rules when reading barcodes

from the screen Because the SP21002D uses an imager, it doesn’t have the restrictions that a typical laser scanner has as

far as how the various types of displays absorb the reflected light of the 650nm laser light.

● The working distance will be shorter - The working distance is the distance (minimum and maximum) between which a

barcode of a certain density will decode. Where the normal working distance is nominally 4-10 inches for a standard

resolution UPC code on printed material, the focal length will be tighter to read the same barcode from the screen. This is

even true when you increase the size of the barcode as recommended above and is mostly due to the absorbed and

reflected light accompanying reading barcodes from a screen.

● It will take longer to read the barcode - It isn’t unusual for it to take the decoder part of the imager - the part that does

the math to determine if the barcode has been correctly and what the characters in the barcode are - to take longer when

reading a barcode from the screen. All the issues noted above have bearing on it. Just be aware that it will data collection

from a screen will not be as fast as you would expect if you’re using scanning printed barcodes as a base line.

Loading...

Loading...