Page 3-4

Maintenance - 3.5 - Blocking Elevating Assembly

SL20

3.5 B

LOCKING

E

LEVATING

A

SSEMBLY

WARNING

!

Never perform service on the work platform in the elevating assembly area while

platform is elevated without first blocking the elevating assembly.

DO NOT stand in elevating assembly area while deploying or storing brace.

DONOTblock elevating assembly with a load in the platform.

DO NOT block elevating assembly with a load in the platform.

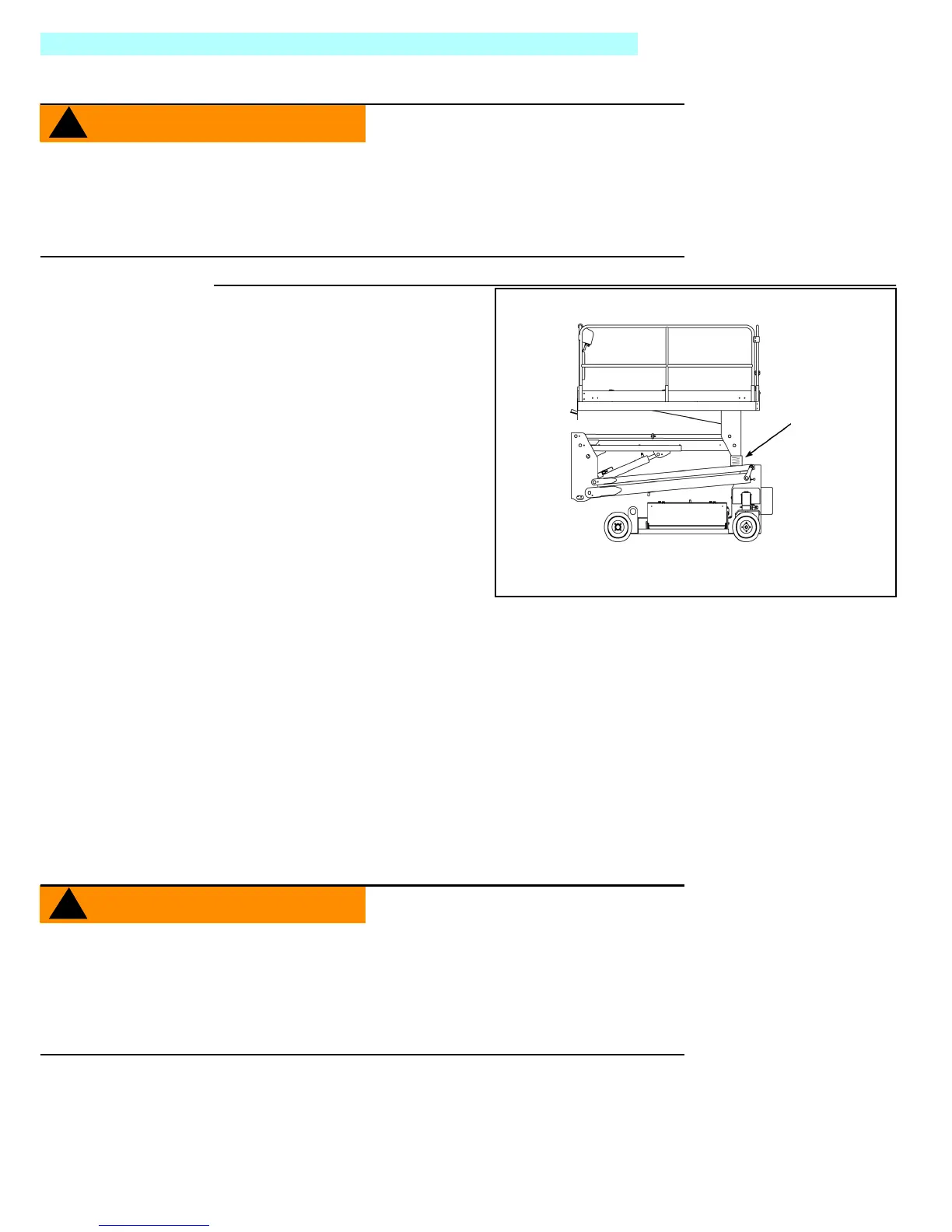

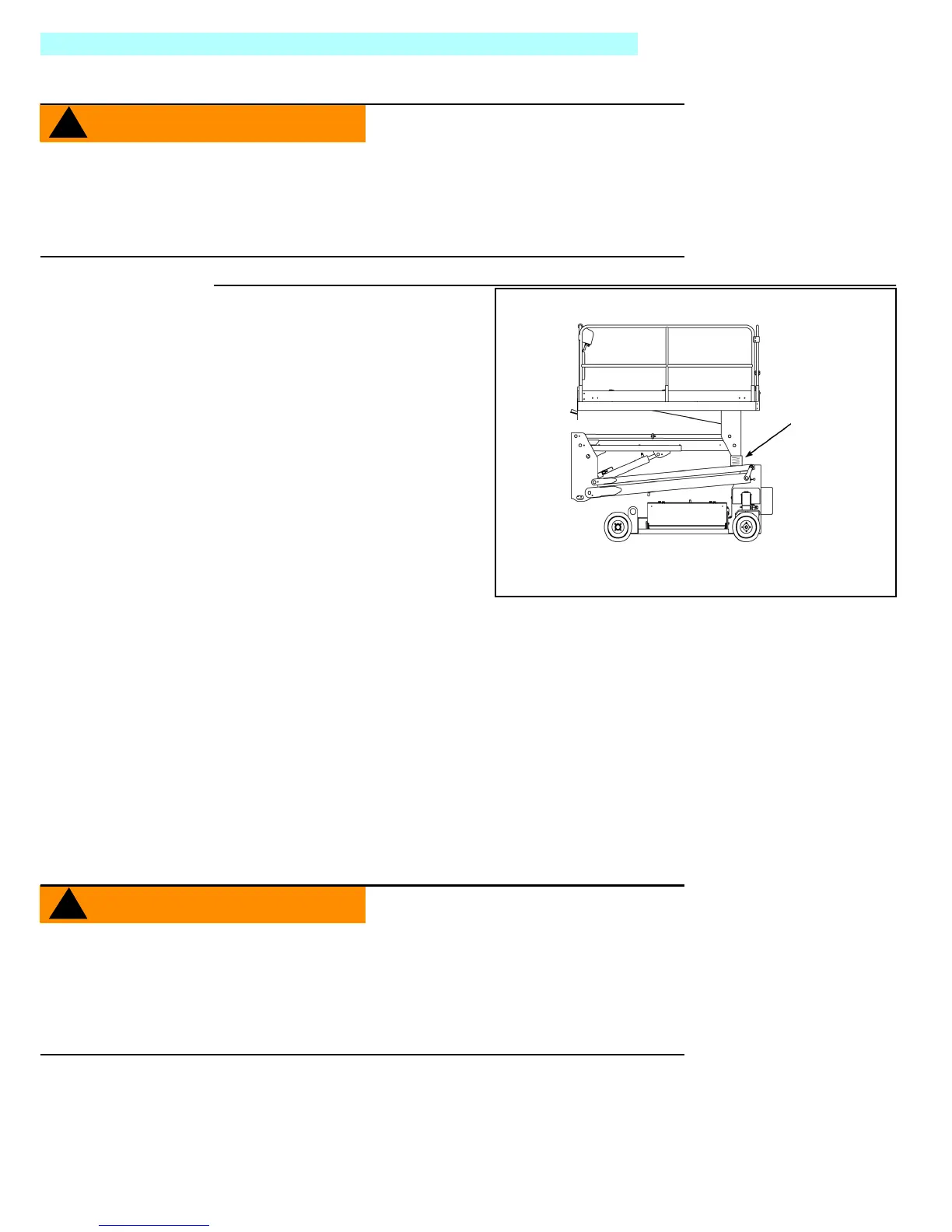

Figure 3-5:

Blocking The Elevating

Assembly

B

RACE

I

NSTALLATION

1. Park the work platform on firm,

level ground.

2. Position chassis lift switch to

LIFT and elevate platform

approximately two feet.

3. Place 10 cm x 10 cm (4inchx

4inch) wood block as shown in

Figure 3-5.

4. Push chassis lift switch to

LOWER position and gradually

lower platform until boom is

supported by the wood block.

B

RACE

R

EMOVAL

1. Push chassis lift switch to LIFT position and gradually raise platform until wood block can be

removed.

2. Remove wood block.

3. Push chassis lift switch to LOWER position and completely lower platform.

4. Close control module cover

3.6 B

ATTERY

M

AINTENANCE

Electrical energy for the motor is supplied by four 6-volt batteries wired in series for 24 volts DC.

Proper care and maintenance of the batteries and motor will ensure maximum performance from

the work platform.

WARNING

!

Hazard of explosive gas mixture. Keep sparks, flame, and smoking material away from

battery.

Always wear safety glasses when working with batteries.

Battery fluid is highly corrosive. Thoroughly rinse away any spilled fluid with clean water.

Always replace batteries with UpRight batteries or manufacturer approved replacements

weighing 28 kg (62 lbs.) each.

B

ATTERY

I

NSPECTION AND

C

LEANING

Check battery fluid level daily, especially if work platform is being used in a warm, dry climate. If

required add distilled water only. Use of tap water with high mineral content will shorten battery

life.

Wood

Block

Loading...

Loading...