6-4b TL33 Work Platform

Section

6.1 Electrical Schematic SERIAL NUMBERS: 1133 TO 1330

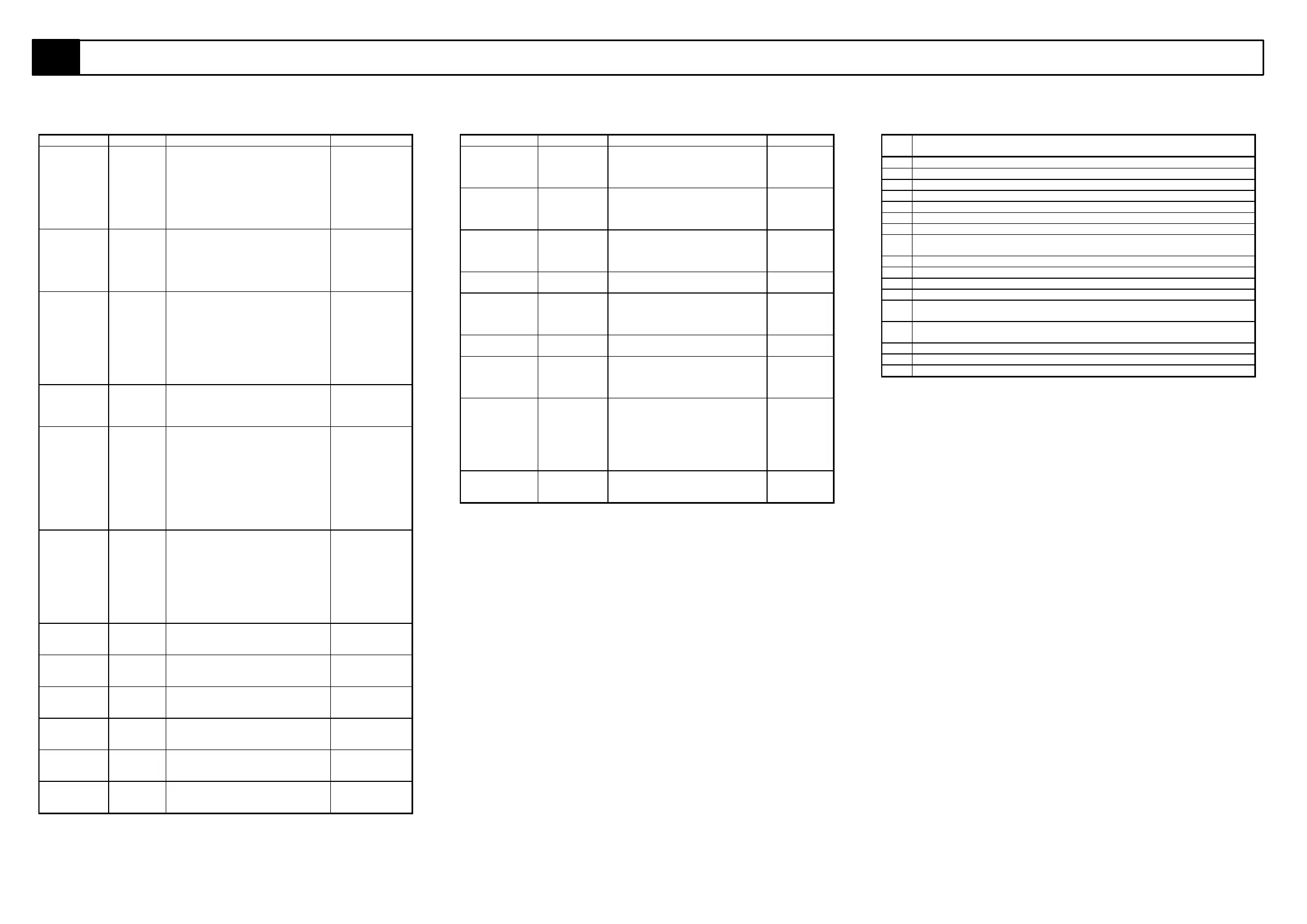

Table 6-1: Electrical Schematic Legend (Contd...)

REFERENCE NAME FUNCTION LOCATION

LS1,LS2,LS3

& LS4.

Outrigger

Limit

Switches.

Activated when the outriggers are

deployed and taking load. +24V

supply from the batteries is routed

through these four limit switches,

which are wired in series, to the

keyswitch and provides power to the

upper and lower control boxes for

operation of the boom functions.

On Outrigger

supports.

LS5 Slew cut-

out limit

switch.

This prevents slewing until the

second post is clear of the tow bar.

The normally closed contact is open

and the slew signal to pin 4 on the

controller is broken until the second

post is clear of the towbar.

On first post

under lower

boom.

MCU Motor

Control

Unit.

This controls the speed of the

electric motor. Using the upper

controls the motor speed varies with

the position of the control joystick.

Using the lower controls the motor

has different fixed speeds for the

various functions which are

programmed into the MCU using a

special calibrator.

Chasis

Subframe.

MOT 24V D.C.

Electric

Motor.

This motor is coupled to the

hydraulic pump which provides the

oil flow and pressure to operate the

various machine functions.

Chasis

Subframe.

RL1 Joystick

direction

relay.

This relay is energised when the

joystick is pushed foward. The

contacts close allowing +24V to be

fed into only one half of the contacts

on the selector switch. This then

allows only one of the two solenoids

on each function spool to be

energised thus allowing only one

direction of motion when the joystck

is pushed forward.

Upper Control

Box P.C.B.

RL2 Joystick

direction

relay.

This relay is energised when the

joystick is pulled backwards. The

contacts close and feed +24V to

opposite set of contacts on the

selector switch as RL1 does. This

then energises the opposite solenoid

for each function and provides

motion in the opposite direction

when the joystck is pulled back.

Upper Control

Box P.C.B.

SOL1 Solenoid Solenoid used for activating

hydraulic valve to slew in the right

direction

Back of first

post.

SOL2 Solenoid Solenoid used for activating

hydraulic valve to raise the first

boom.

Back of first

post.

SOL3 Solenoid Solenoid used for activating

hydraulic valve to raise the second

boom.

Back of first

post.

SOL4 Solenoid Solenoid used for activating

hydraulic valve to slew in the left

direction

Back of first

post.

SOL5 Solenoid Solenoid used for activating

hydraulic valve to lower the first

boom.

Back of first

post.

SOL6 Solenoid Solenoid used for activating

hydraulic valve to lower the second

boom.

Back of first

post.

REFERENCE NAME FUNCTION LOCATION

SW 1 Function

switch Lower

Boom.

Sends power to the lower lift

cylinder solenoid which diverts oil

to full bore or annular side of lower

lift cylinder.

Lower

control box.

SW 2 Function

switch Upper

Boom.

Sends power to the upper lift

cylinder solenoid which diverts oil

to full bore or annular side of upper

lift cylinder.

Lower

control box.

SW 3 Function

switch slew.

Sends power to the slew motor

control solenoid which diverts oil to

the left or right side of the slew

motor.

Lower

control box.

SW 4 Emergency

stop button.

Control circuit shut off. Lower

Control Box.

SW 5 Switch-

3 position

selector

Sends power to selected solenoid

valve (lower lift, upper lift, tele &

slew). Only one function can be

selected at any time.

Upper

Control Box.

SW 6 Emergency

stop button.

Control circuit shut off. Upper

Control Box.

SW 7 Switch,

Emergency

Override.

Provides emergency power when

power is cut to the upper controls

due to an outrigger limit switch de-

activating.

Upper

Control Box.

SW 8 Swith On/Off Allows +24V supply to feed upper

controls. Allows signals from tele

and lift functions to pass down to

the controller. Allows joystick

trigger signal to pass down do the

controller. (this switch is combined

in the same housing as SW7)

Upper

Control Box.

TS 1 Tilt Alarm.

(option)

This is a warning device that will

sound if the machine tilts at an

angle greater than 3 degrees

Chasis

Subframe.

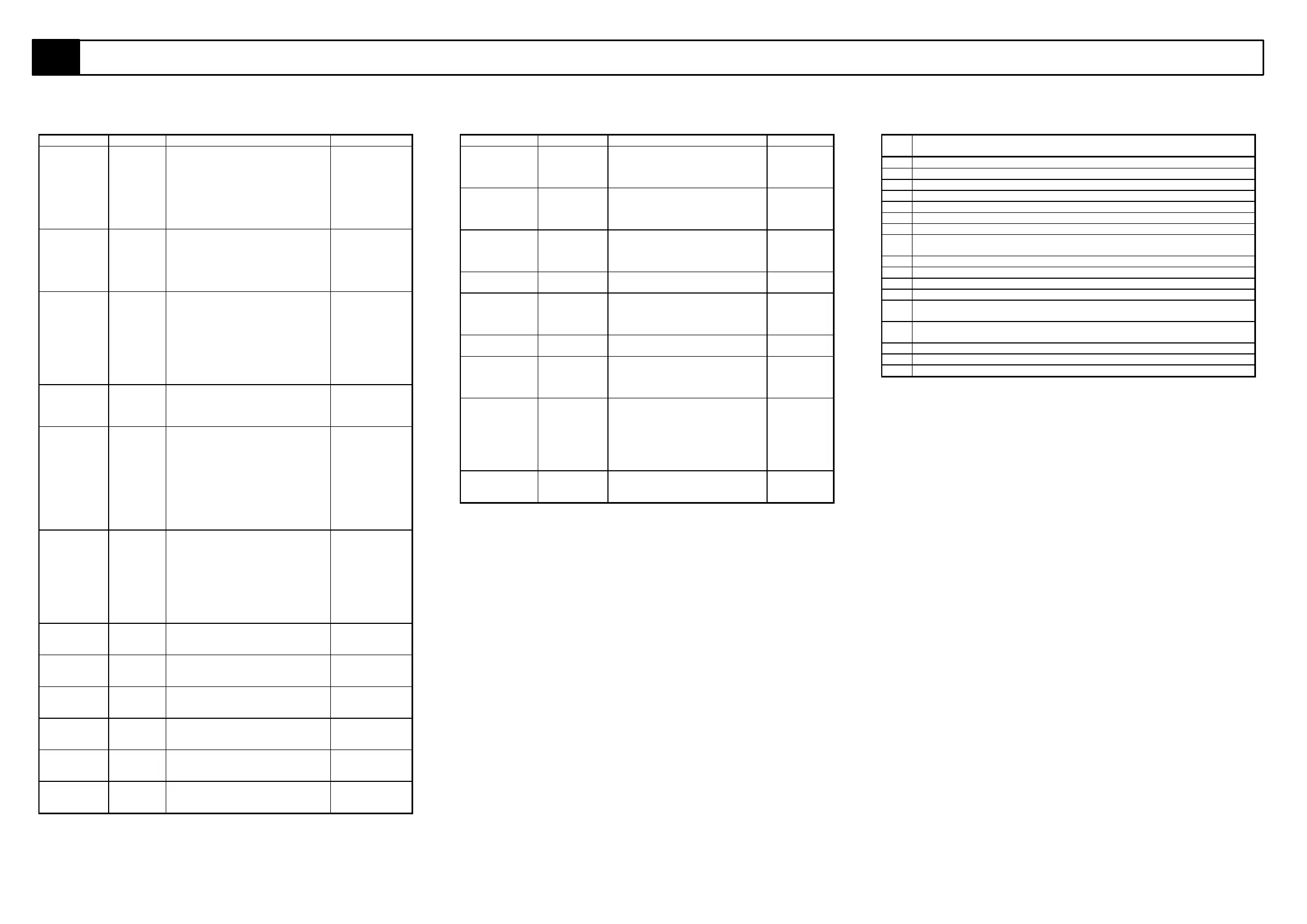

MOTOR CONTROL UNIT (PIN LEGEND)

PIN

No.

DESCRIPTION

1 Battery Discharge Indicator (B.D.I.) output

2 Not used - sw8 - Switch 8

3 Not used - 10V supply

4 sw4 - Switch 4 (Speed 4: slew speed from lower controls - Factory set at 13%)

5 Not used - Not connected.

6 24V supply (Must be greater than 14V)

7 Not used - Not connected.

8 sw1 - Switch 1 (speed 1: Max. variable speed for upper and lower lift cylinders

from upper controls - Factory set at 90%)

9 Not used - Not connected.

10 Not used - Not connected.

11 Not used - Not connected.

12 sw3 - Switch 3 (Speed 3: Boom speeds from lower controls - Factory set at 45%)

13 sw2 - Switch 2 (Speed 2: Max variable slewing speed from upper controls -

Factory set at 40%)

14 Accelerator (3.5V - 0V) - Input from joystick to vary motor speed from upper

controls.

15 Not used - Not connected.

16 Not used - Not connected.

17 Not used - Not connected.

Loading...

Loading...