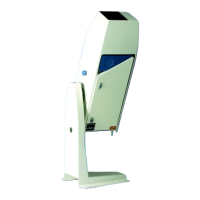

Ceilometer CT25K

CT25K-U059en-2.1 User’s Guide

103

Check that the transmitter is now in the correct position, that is, the sides

of the transmitter case are approx. parallel with the edges of the lower

part of the Optical Subassembly.

If this is not the case, loosen the attachment ring first, then correct the

transmitter position and fasten as described above.

2. Attach the ribbon cable connector to the DMF51 Board Frame to

connector J10. Refer to Figure 8-1.

3. Connect the Power Cable and the Maintenance Terminal. Turn the power on.

4. If the transmitter has been replaced by a new one, do the following:

a) Open the command set by first typing OPEN↵ at the command

prompt and then typing the password ADVANCED↵.

b) Interrupt autoadjustments with the command

STOP↵

Then give the following commands

SET DATA_ACQ AUTOADJ OFF↵ sets the autoadjustments off

SET PORT TIMEOUT 20↵ sets the timeout of the dialog to

20 minutes

SET DATA_ACQ INTERVAL 15↵ sets interval for measurement

and message sending to 15

seconds

c) First check the prevailing settings with the command

GET FACTORY↵

The value of INLASER tells the prevailing factory setting of the

Transmitter Calibration Factor.

d) Note the Calibration Factor of the transmitter (written on the

subassembly). If the transmitter has been replaced and the

Calibration Factor differs from the prevailing factory setting, give

the new Calibration Factor value (= new factory setting) with the

command:

SET FACTORY INLASER↵

and type the new Calibration Factor value ↵.

e) Set the laser power into effect with the command

SET DATA_ACQ TRANSMIT POWER_OF_P↵

and type the new value (= Calibration Factor) ↵. (The same

Calibration Factor value as in step d).

Loading...

Loading...