The hardware configuration is finished, now and the CPU may always

be accessed by the IP parameters as well by means of WinPLC7.

Usually the online transfer of the hardware configuration

happens within the hardware configurator. With

‘File

è Save active station in the WinPL7 sub project’ there is

also the possibility to store the hardware configuration as a

system file in WinPLC7 to transfer it from WinPLC7 to the

CPU.

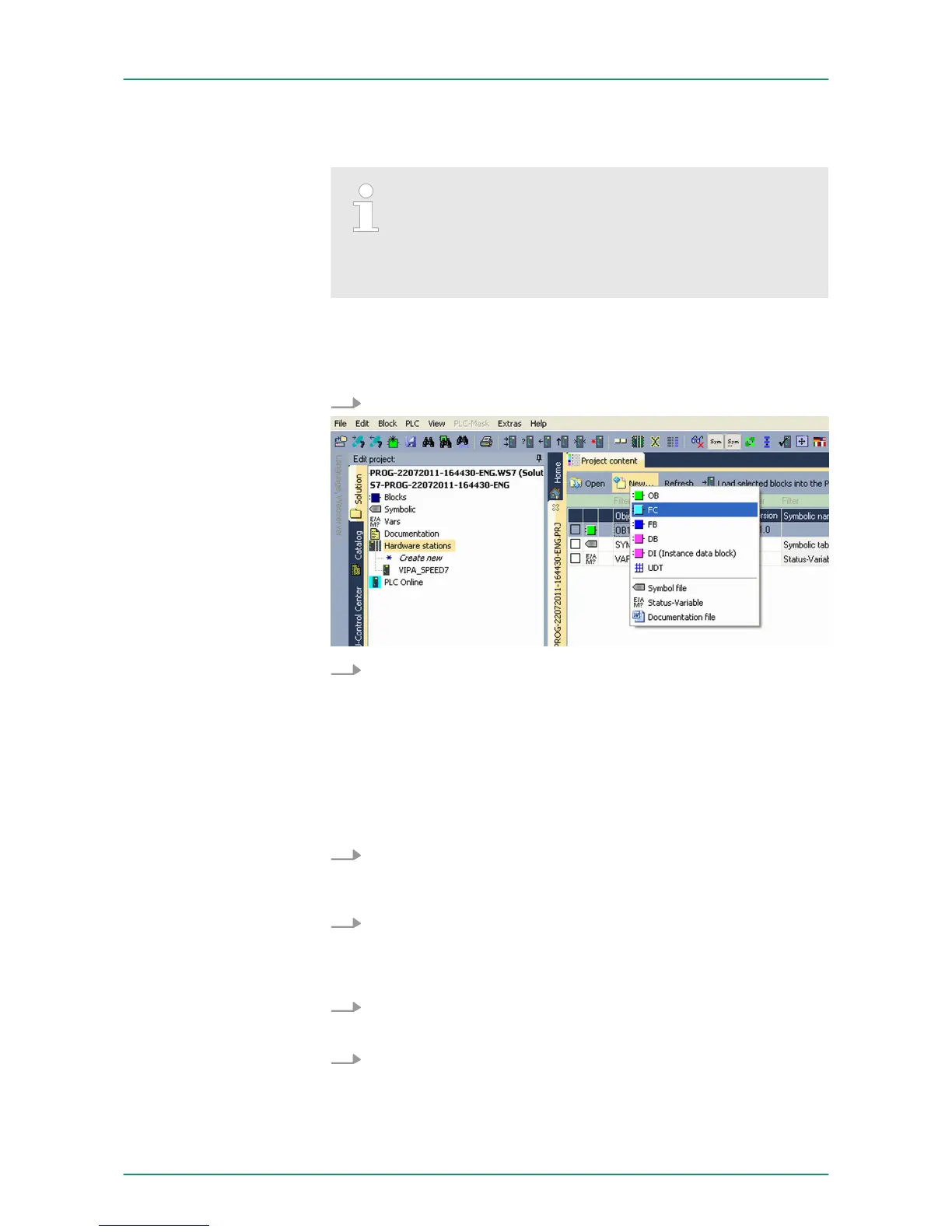

The PLC programming happens by WinPLC7. Close the hardware

configurator and return to your project in WinPLC7. The PLC program

is to be created in the FC 1.

1.

In ‘Project content’

choose ‘New è FC’.

2. Enter "FC1" as block and confirm with [OK].

ð

The editor for FC 1 is called.

Creating parameters

In the upper part of the editor there is the parameter table. In this

example the 2 integer values value1 and value2 are to be compared

together. Since both values are read only by the function, these are to

be defined as "in".

1.

Select the ‘in

à

’ row at the ‘parameter table’ and enter at the

field ‘Name’ "value1". Press the [Return] key.

ð

The cursor jumps to the column with the data type.

2. The data type may either directly be entered or be selected from

a list of available data types by pressing the [Return] key. Set

the data type to INT and press the [Return] key.

ð

Now the cursor jumps to the ‘Comment’ column.

3. Here enter "1. compare value" and press the [Return] key.

ð

A new ‘in

à

’ row is created and the cursor jumps to ‘Name’ .

4. Proceed for value2 in the same way as described for value1.

Programming of the

FC 1

VIPA System 300SWinPLC7

Example project engineering > Project engineering

HB140 | CPU-SC | 313-6CF13 | GB | 15-50 190

Loading...

Loading...