95x Series Operating Manual - May 17, 2022

Page 84 of 155

If there is more than nominally 1.5V peak between the respective SOURCE and SENSE terminals of the 95x then

the test is failed with a WIRING FAULT condition – the user must ensure that sufficient wire gage is used for the

SOURCE wires (there is very little current flow in the SENSE wires).

If the user needs to make optimum measurements of low impedances, particularly less than a few 10’s of mΩ,

then the following points should be considered -

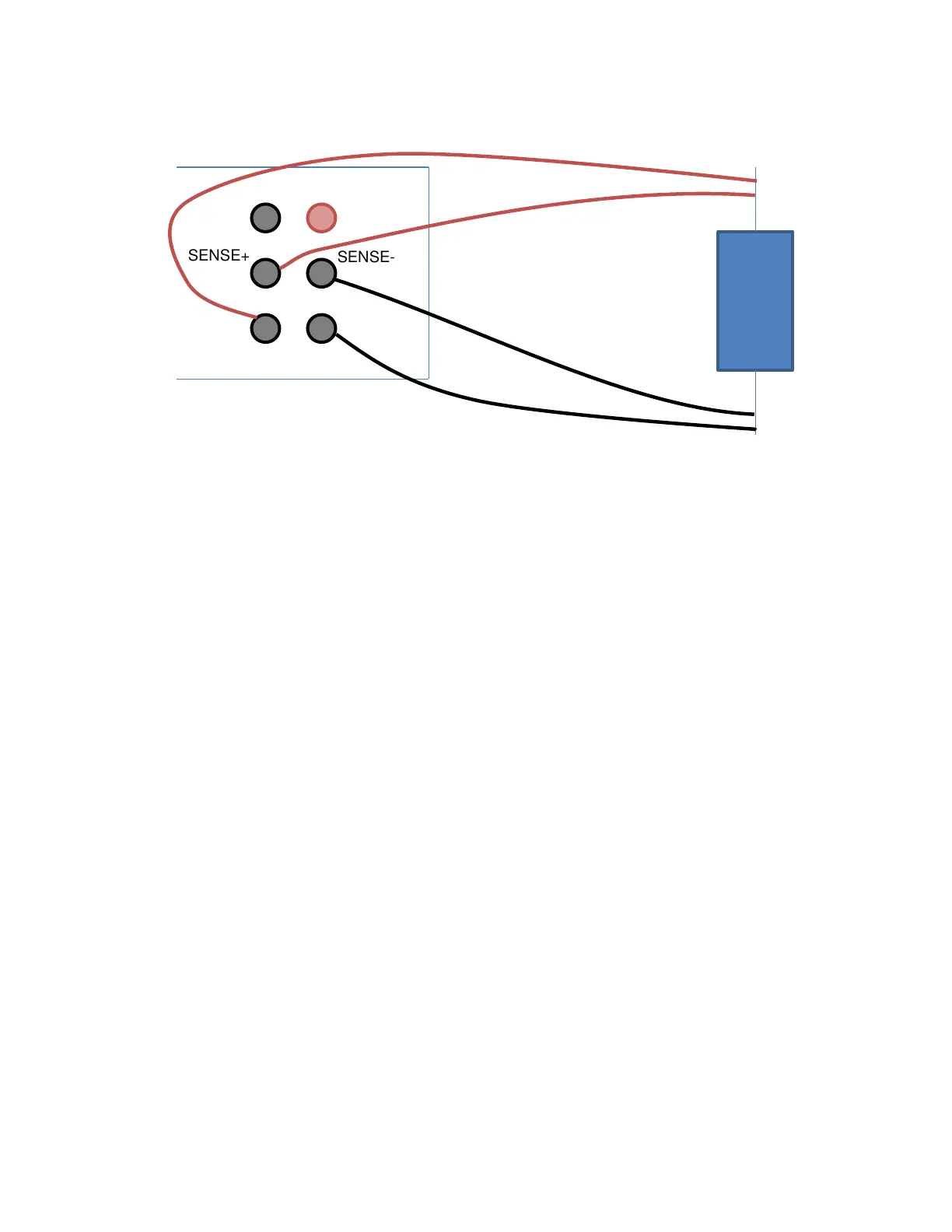

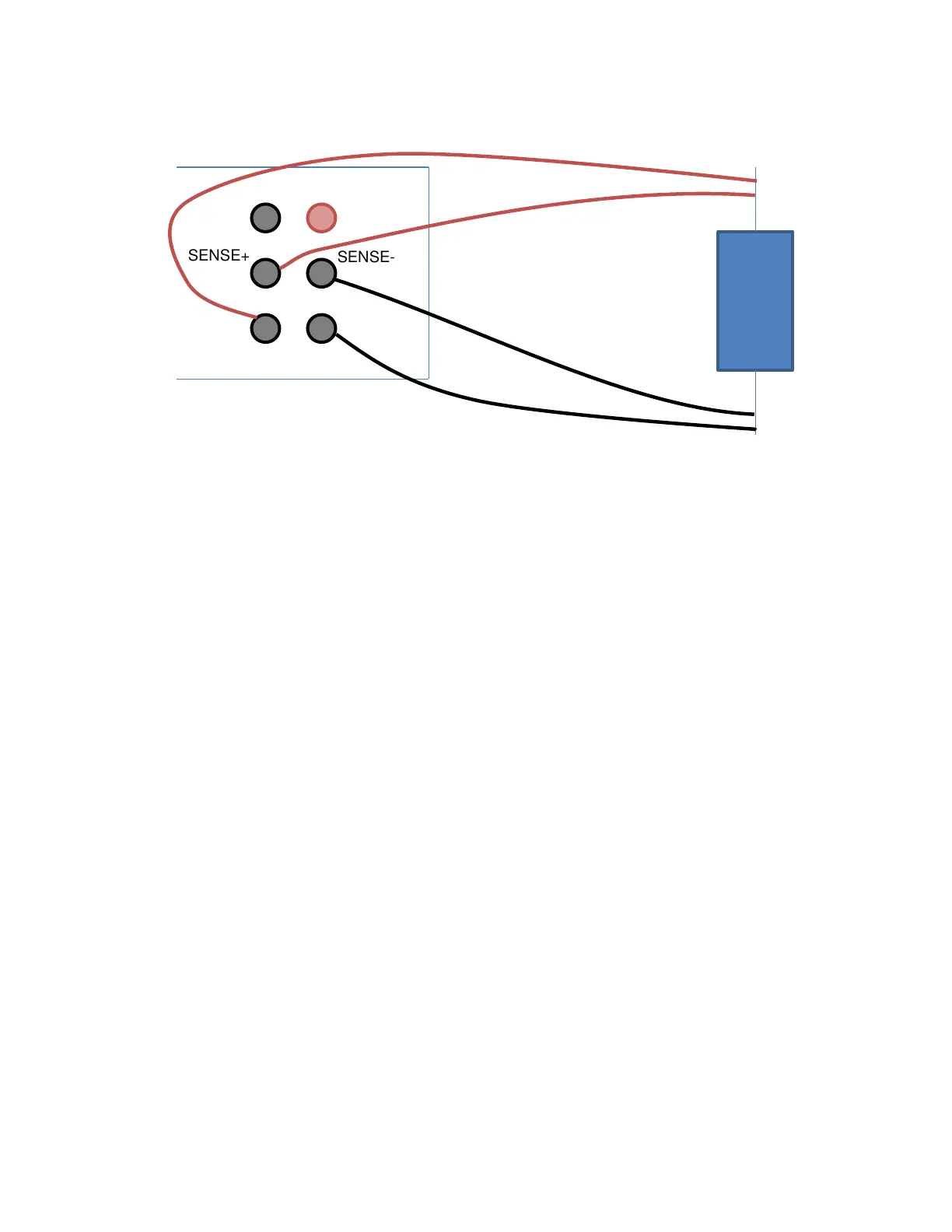

• The user should be aware that inductive coupling between the current flow in the SOURCE wires and the

respective SENSE wires will cause errors in the measurement results. If the wires are longer than a few

feet and/or are tightly coupled then these errors can be 10’s of milliohms at 60Hz and significantly more

at 400Hz, particularly when high test currents are being used. This effect is not specific to the 95x, it

applies to any high current, low impedance AC measurement.

• When making very low-level measurements or when using long lengths of wiring, the user is

recommended to couple (e.g., use a twisted pair) the SOURCE wires together and/or couple the SENSE

wires together for at least the majority of the wire length. Alternatively, if the user maintains at least a ¾“

spacing between each wire and all other wires then these effects are also reduced.

• Similarly, there will be some inductive coupling between the DUT and the SENSE wires if they are not

separated from the DUT sufficiently, to reduce this the SENSE wires should not rest on or close to the DUT

but should be routed nominally 90° away from the DUT for at least several inches.

• The coupling effects described above will almost always yield a higher-than-expected measurement. If

the users’ test passes with the measurement within the allowable range of impedances, then, even if

these are not accounted for, the DUT is guaranteed to have passed the test – the above effects may only

cause a false failure of the test.

Use caution when handling the connections to the DUT after performing a test. If high currents are being used

then the power in the contact resistance between the DUT and the SOURCE wires, particularly when using clips,

may be high, causing the contacts to become hot – at 40A the power in 1mΩ is 1.6Watts. Similarly, the user

should ensure that the connections to the front panel SOURCE terminals are fully secure – the user is

recommended to use lugs and not plug-in connectors for currents above 10A.

Loading...

Loading...