21

PEM-X1

P_01664

P_01664

P_01665

OPERATING MANUAL

VERSION 09/2012 ORDER NUMBER DOC 2326020

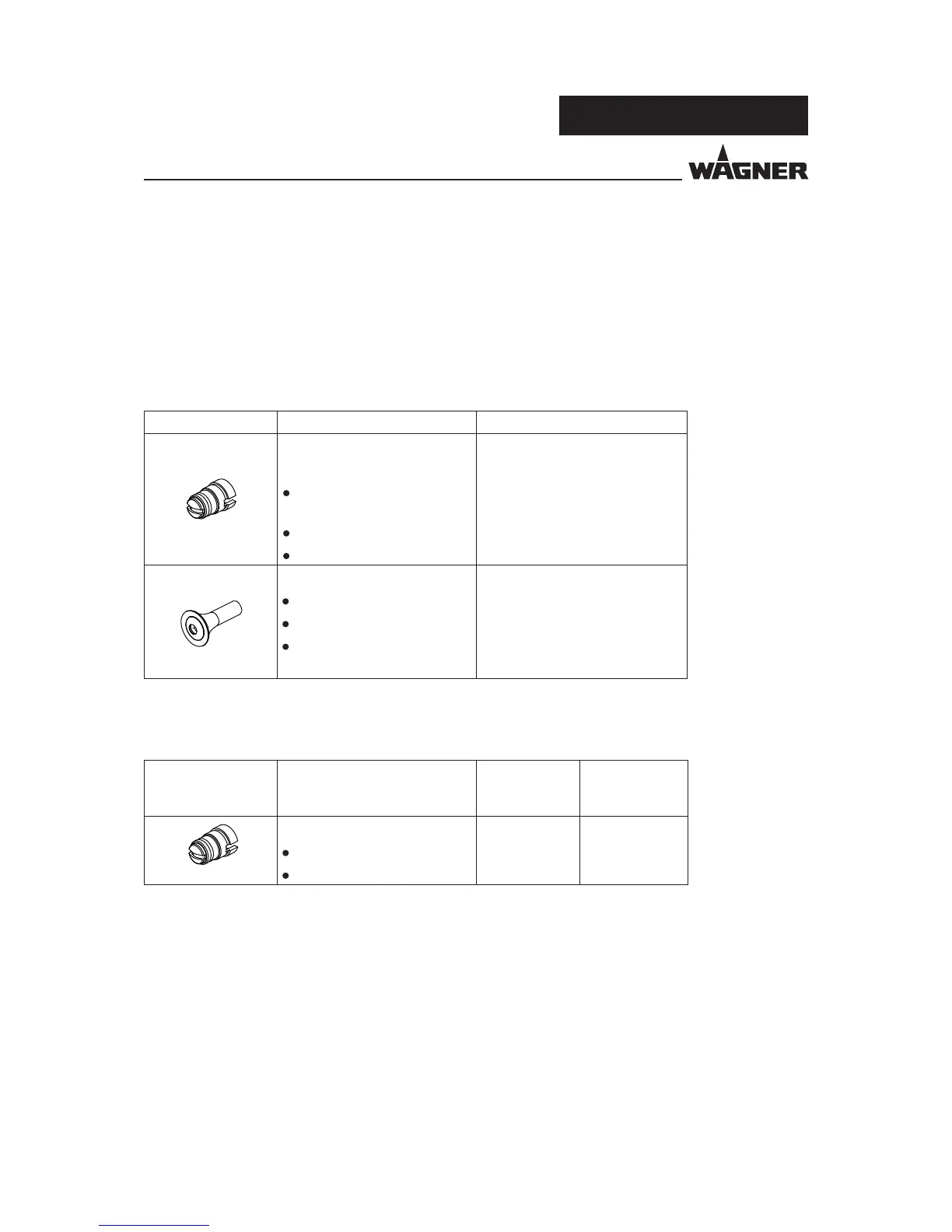

6.4 PREPARING THE SPRAY GUN

6.4.1 SELECTION OF THE SUITABLE NOZZLE SYSTEM

Nozzle Application Distance to

work piece

Powder

discharge

(mm) (g/min)

Universal

120 … 300 50 … 300

deep and complex shapes

extensive work pieces

Nozzle Application overview Powder cloud

Flat spray nozzle Complex shapes Widely spread at powder cloud

Flat parts (slight window

frame e ect)

Pro les

Undercuts

De ector cone Round powder cloud:

Wire goods Size of the powder cloud is

dependent on the de ector

plate diameter

Grid designs

Small components

The process of changing from the at spray nozzle to the de ector cone is described in

chapter 8.8 "Changing from Flat Spray Nozzle to Round Spray Nozzle".

You will nd the article numbers of the di erent nozzles in chapter 12 "Accessories".

Loading...

Loading...