SSW7000 | 5-27

Installation and Connection

■ Minimum insulation voltage of the cables according to the power supply.

Commercial examples: Cofiban – Cofialt, Pirelli – Eprotenax, Ficap – Fibep.

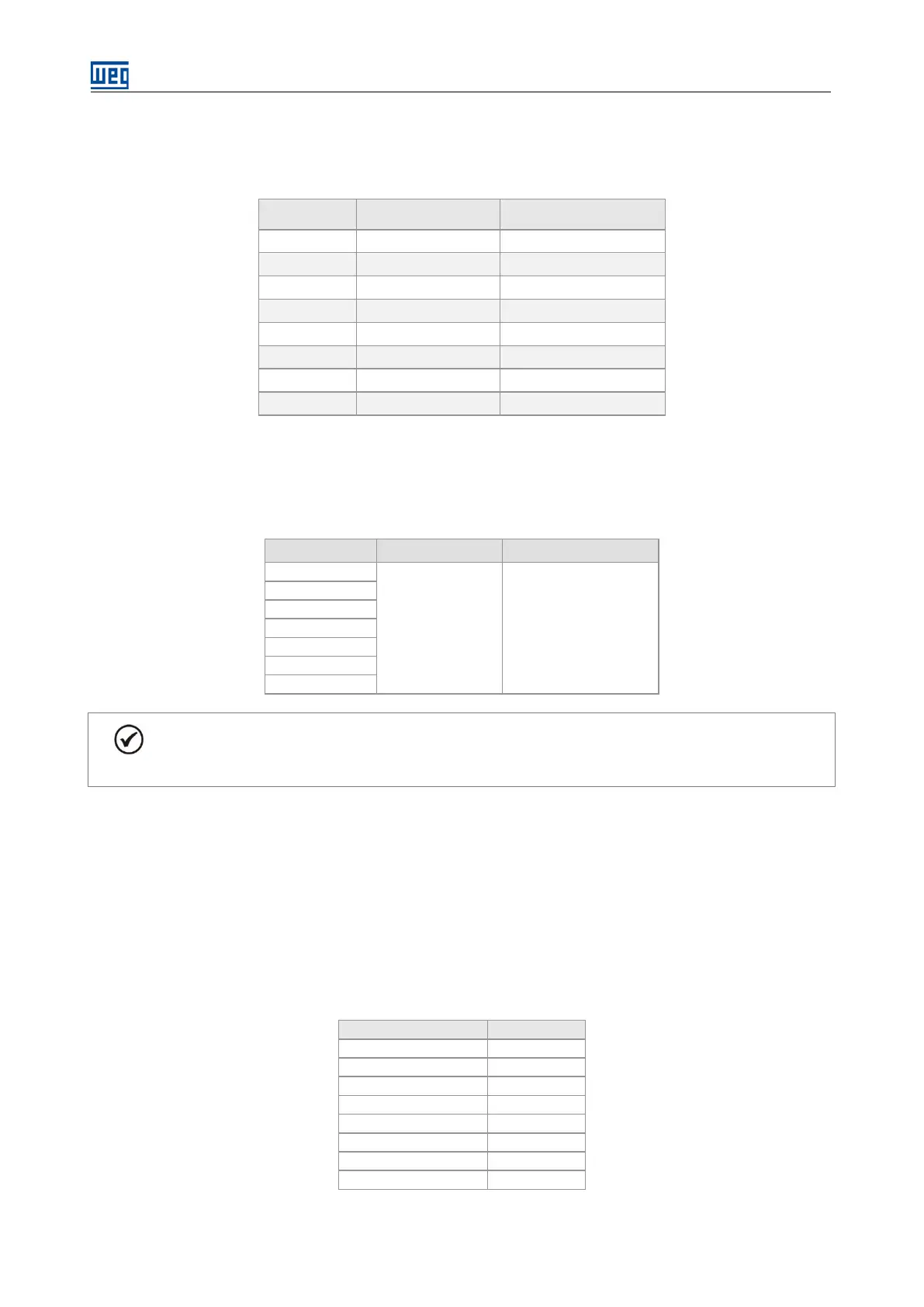

Table 5.19: Recommended cable for 100 % of the rated current

Power Cable Cross

Section mm² (in²)

Grounding Cable Cross

Section mm² (in²)

70 A 35 (0,06) 25 (0.04)

125 A 50 (0.08) 25 (0.04)

180 A 70 (0.11) 35 (0.05)

250 A 150 (0.24) 95 (0.15)

300 A 185 (0.29) 95 (0.15)

360 A 240 (0.37) 120 (0.19)

500 A 2 x 150 (2 x 0.24) 2x 95 (2 x 0.15)

600 A 2 x 185 (2 x 0.29) 2x 95 (2 x 0.15)

■ Use adequate lugs for the power and grounding connections.

■ Tighten the connections with the adequate torque.

Table 5.20: Tightening torque at the power connections

M10 30

T / 5L3

U / 2T1

V / 4T2

W / 6T3

Grounding

For the correct selection of the cables consider the installation conditions, the maximum allowed

voltage drop and use the applicable local regulations on electrical installations.

5.2.5. Fuses

In the panel IP41, the R-type fuses are installed inside the cabinet, close to the disconnect switch, and they protect

both motor and installation against short circuit. They must comply with the rated medium voltage supply voltage.

In the panel Nema 12 the disconnect switch is installed in the medium voltage upper compartment and the R-

type fuses are in the medium voltage lower compartment beside the line and bypass contactors.

The table 5.21 presents the fuses used in the standard SSW7000. They comply with the standard operational

SSW7000 capacity.

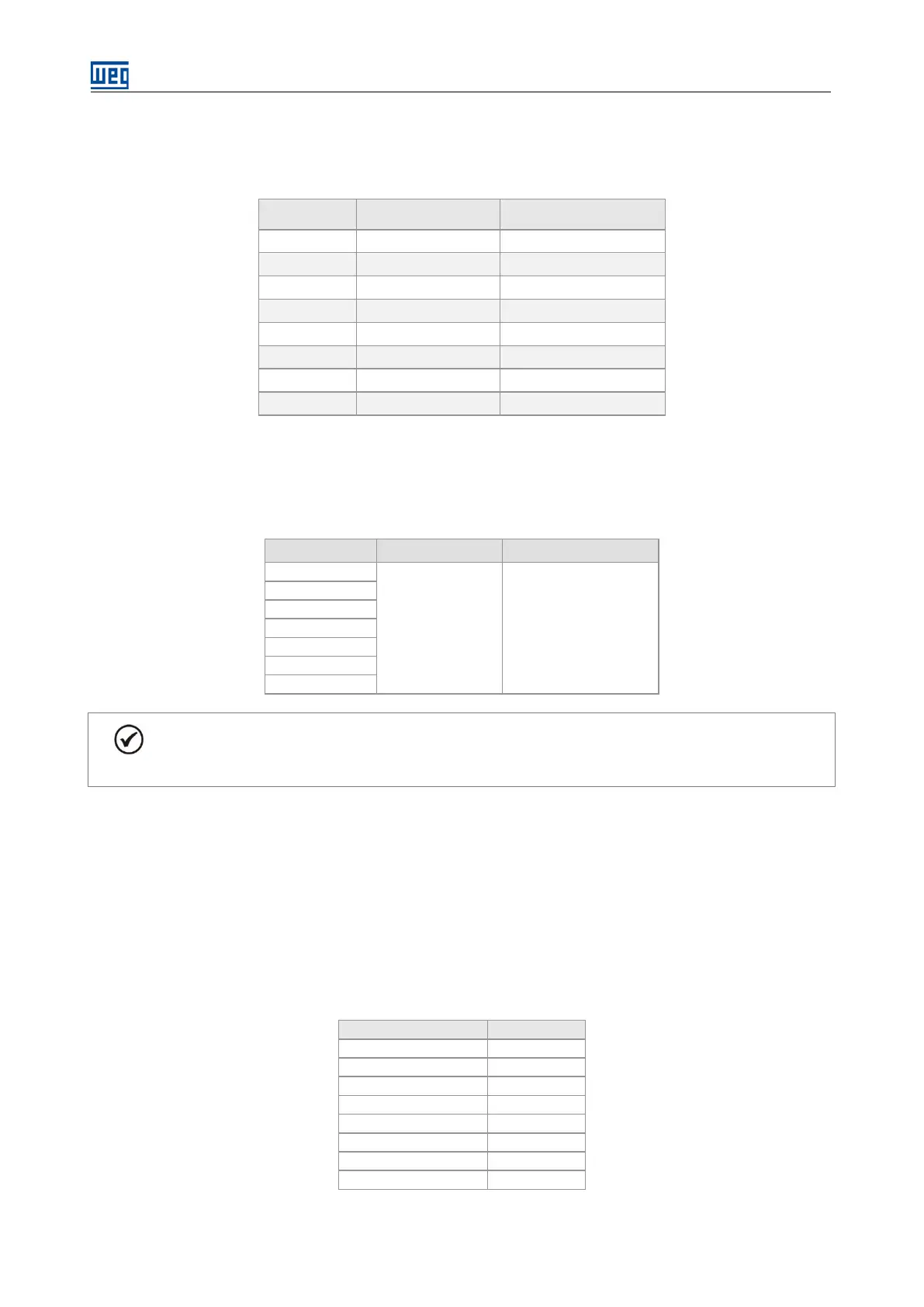

Table 5.21: Recommended fuses

70 A 9R (or 6R)

125 A 9R (or 6R)

250 A 18R

300 A 18R

360 A 24R

500 A 38R

600 A 44R (or 48X)

Loading...

Loading...