WEILER E1650 REMIXING TRANSFER VEHICLE

3-33

Operating Instructions

3

Cleaning or Removing Material

Discharge Conveyor Cleanout

The discharge conveyor is equipped with access doors to

the discharge conveyor slats and chain for inspection,

cleaning and material removal. In the event that a

stalled discharge conveyor cannot be started by

alternating conveyor between reverse and forward, use

the following steps to remove material to free the

conveyor:

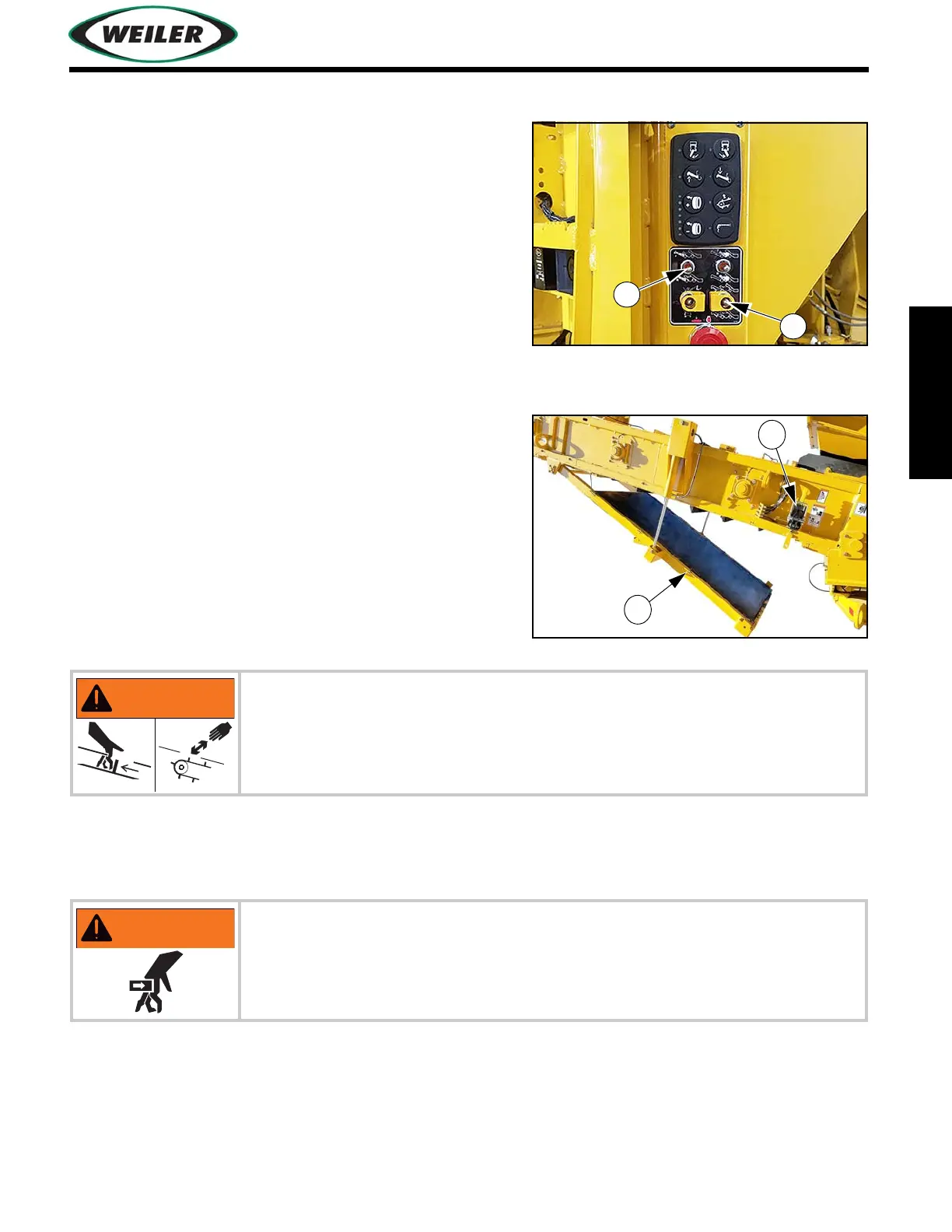

1. Use Manual Conveyor Switch (1) to reverse the

discharge conveyor, if conveyor is empty.

If discharge conveyor is full, alternate switch

between reverse and forward to rock conveyor chain

to attempt to free the conveyor.

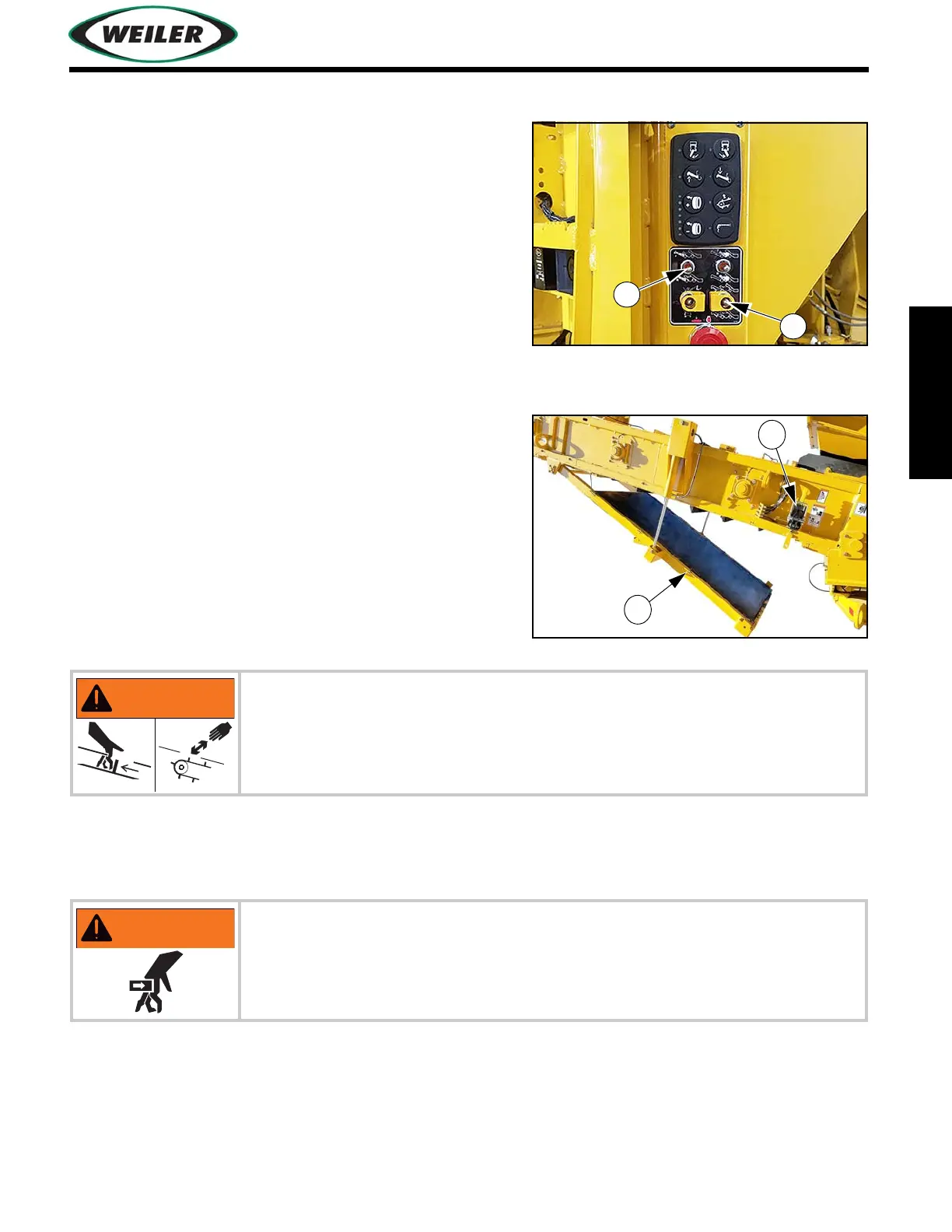

2. Raise conveyor to a position that allows cleanout

door (2) to be lowered.

3. Release cleanout door latches (3).

4. Raise conveyor and use Conveyor Cleanout Door

Switch (4) to open cleanout door.

5. Remove material by nudging conveyor.

6. Turn engine off and remove material from door. Thoroughly clean sealing edges of door and

opening to enable doors to fully close.

7. Close and latch cleanout door.

WARNING

Moving conveyor slats can crush or cut off fingers and hands.

Never reach into conveyor chute or insert a cleanout tool into conveyor

chute when conveyor is moving. Stop engine and remove ignition key

before cleaning or servicing conveyor.

WARNING

Contact with moving parts can cut or crush.

Make sure no one is working on, underneath, or close to machine before

starting engine and closing doors. Ensure area is free of personnel. Keep

spectators away.

Loading...

Loading...