Operation

7218−1/A1

Winterthur Gas & Diesel Ltd.

5/ 19

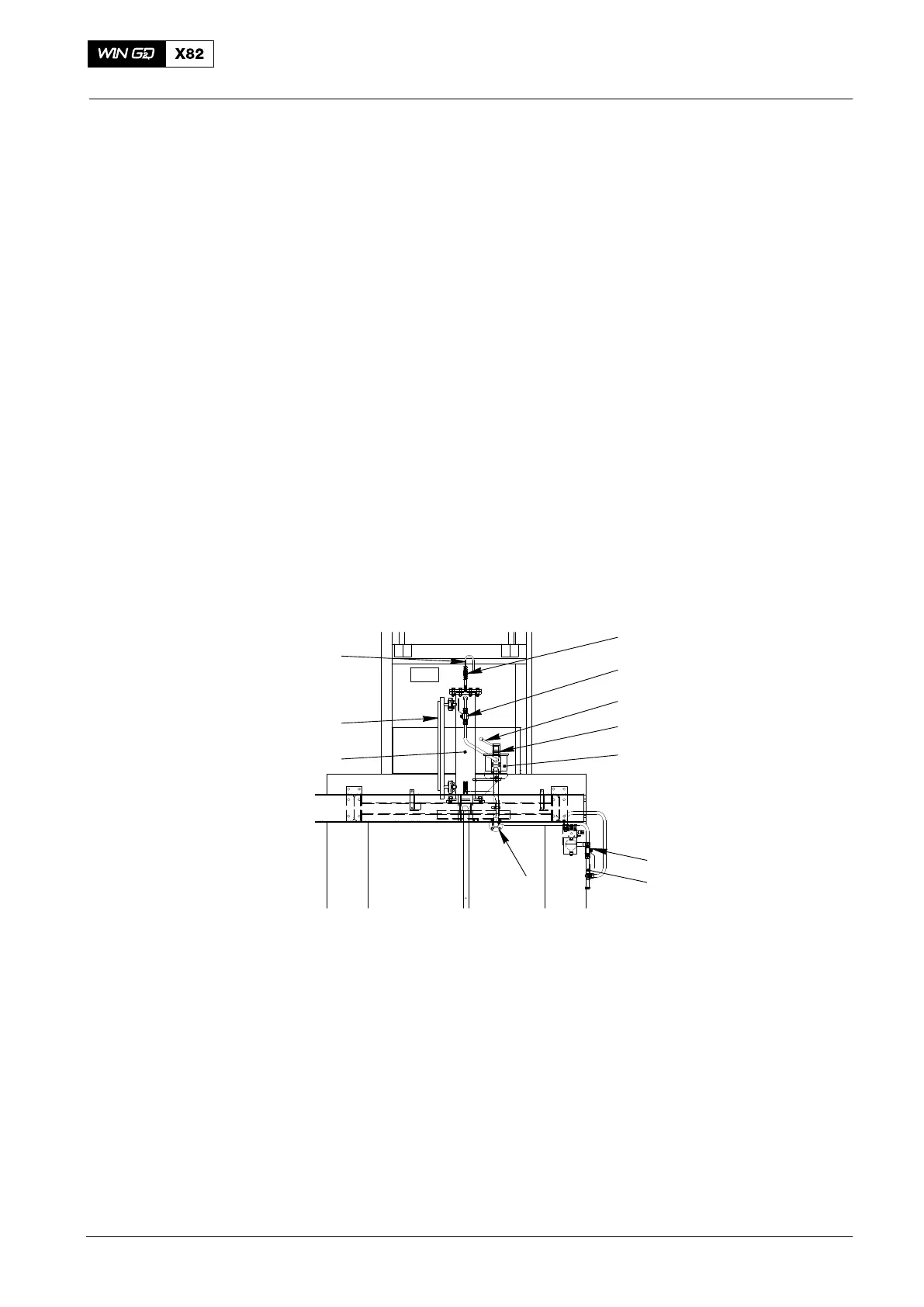

3. Duplex Filter and Measurement Tube

The duplex filter (1, Fig. 3) and the measurement tube (4) are installed between the

lube oil tank and the lubricating pumps. The differential pressure sensor (6) monitors

the quantity of dirt in the duplex filter (1). If the filter is clogged, the differential

pressure sensor transmits a signal with a failure message to the alarm and monitoring

system. If the filter element becomes clogged, replace it (see paragraph 3.2).

Note: Make sure that the ball valve (8) is opened during operation.

3.1 Duplex Filter

It is necessary to bleed the duplex filter:

D At the first operation

D After you replaced a filter element.

3.2 Filter Element

It is possible to replace a clogged filter element during operation, thus it is not

necessary to stop the oil supply. Do the steps that follow:

1) Move the lever (2, Fig 3) to the other (clean) filter element.

2) Replace the clogged filter element.

019.324/10

4

7

2

1

9

10

6

5

8

3

11

Fig. 3: Duplex Filter and Measurement Tube

1 Duplex filter 8.17 7 Scale

2 Lever 8 Ball valve

3 Supply pipe 9 Ball valve

4 Measurement tube 8.19 10 Supply pipe

5 Ball valve 11 Air vent

6 Differential pressure sensor PS3121A

2014

Cylinder Lubrication

Loading...

Loading...