Operation8019−1/A2

Winterthur Gas & Diesel Ltd.

6/ 13

4. Fuel Leakage System

4.1 Leakage Inspection Points

You use the leakage inspection points to help you find possible leakages from the HP

fuel pipes.

The level switches (LS) (20, Fig. 1) to (25) monitor all important leakages in the fuel

system.

If there is too much leakage, the related alarm is activated.

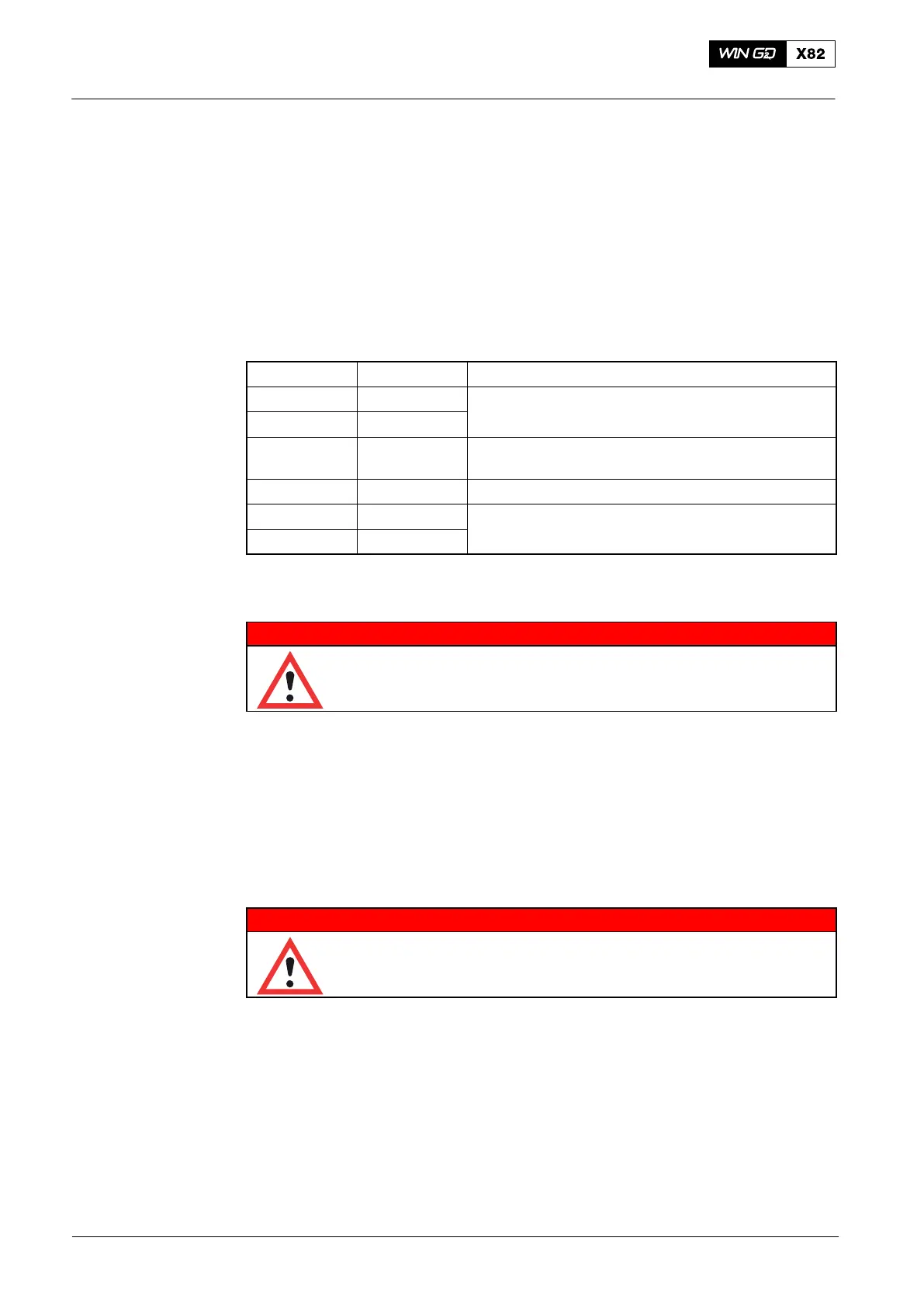

Level switch

Location Monitored components

LS3444A Driving End Leakages (fuel and servo oil) from the rail unit

LS3445A Free End

LS3446A Driving End HP fuel pipes (17), injection control units (ICU) (16)

and related fuel overpressure safety valves (32)

LS3447A Free End HP fuel pipes (17), ICU (16), connection pipes (14)

LS3426A Fuel Side HP fuel pipe (9), HP fuel pipes (10), and fuel

pumps (3) and fuel pump covers

LS3427A Exhaust Side

4.2 Leakages

WARNING

Injury Hazard: Always put on gloves and safety goggles when you

do work on hot components. When you open the screw plugs,

fuel can come out as a spray and cause injury.

If the level switches (20, Fig. 1) (LS3426A), (21) (LS3427A), (22) (LS3446A) or

(23) (LS3447A) activate an alarm, do the procedure that follows:

1) Loosen the related drain screws (see Fig. 4 and Fig. 5).

2) Loosen the plug (6, Fig. 6).

This will help you find the leakage. You can then do the related procedure.

4.3 HP Fuel Pipes 3.29 − Leakage

WARNING

Injury Hazard: Always put on gloves and safety goggles when you

do work on hot components. When you open the screw plugs,

fuel can come out as a spray and cause injury.

If the level switch (20, Fig. 1) (LS3426A) or (21) (LS3427A) has activated an alarm,

do the procedure that follows:

1) On the HP fuel pipe 3.29 (6, Fig. 4), carefully loosen each of the drain screw (7)

approximately two turns.

2) Do a check to see if fuel flows out or not as follows:

a) If fuel flows out, the related HP fuel pipe (6) is defective.

b) If fuel does not flow out, tighten the drain screws (7).

2015-05

Fuel System 9-cylinders

Loading...

Loading...