Maintenance1132−1/A1

RT-flex58T-D

Winterthur Gas & Diesel Ltd.

2/ 3

3. Tensioning the elastic studs

After fitting the main bearing cover as described in 1132−2, elastic studs 1 are to be

tensioned as follows:

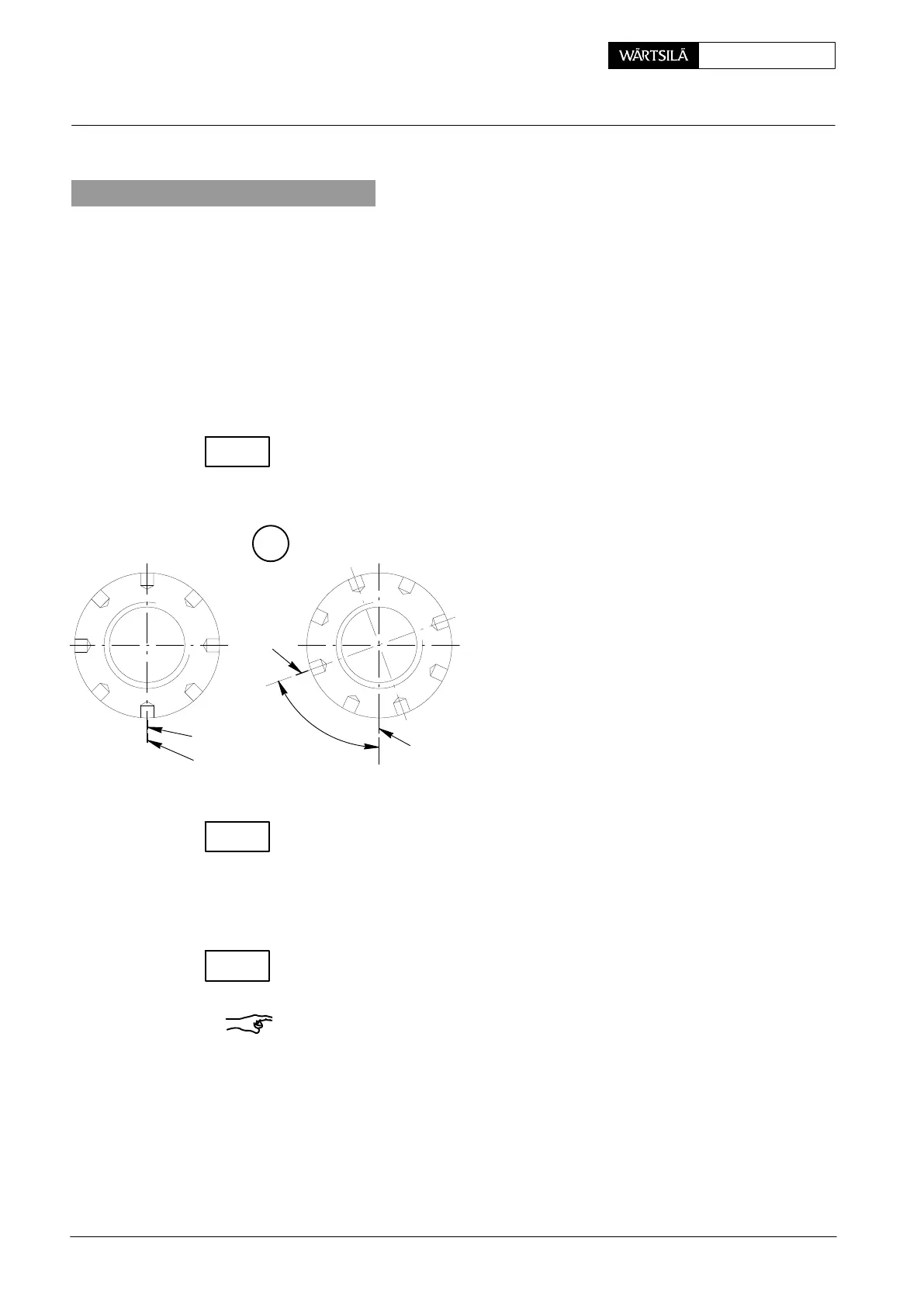

⇒ Place both double pre-tensioning jacks 94114 onto elastic studs 1 for the main

bearing (Fig. ’C’).

⇒ Connect both double pre-tensioning jacks by HP hoses 94935, connection

block 94934 and hydraulic distributor 94932 with hydraulic unit 94942 (ar-

rangement see Fig. ’C’).

⇒ Screw on nuts 4 of the double pre-tensioning jacks till piston 5 fully seat on

cylinders 6 (Fig. ’B’).

The pistons are fully down on the cylinders when distance ’L’ is about 23 mm, mea-

sured from the top of the piston to the upper edge of cover 7.

Check the oil level in hydraulic unit 94942.

⇒ Actuate the hydraulic unit, adjust the

pressure to 1500 bar and keep it

constant.

⇒ Mark the position of nuts 3 against

bearing cover = 1

st

step (Fig. ’A’).

⇒ Tighten all nuts 3 with round bar ’RS’

until firmly seated.

TIGHTENING

ANGLE

1

ST

STEP 2

ND

STEP

009.668/02

A

y

x

y

x

010.357/02

Using feeler gauge 94122 inserted in slot ’KO’, check if there is no clearance at

hand between the nuts and the seating surfaces (2

nd

step).

No clearance must also be at hand between main bearing girder 8 and main bear-

ing cover 2 (Fig. ’C’)!

⇒ Release pressure to zero at the hydraulic unit and then remove both double

pre-tensioning jacks.

Check if all the nuts have been turned by about the same value.

Finally check the horizontal and vertical clearance by means of special feeler

gauge 94123 (see Clearance Table 0330−1 ’Crankshaft and main bearing’).

Remark: All main bearing clearance values are valid only with tightened tie rods

and elastic studs.

Main Bearing: Loosening and Tensioning of Elastic Studs

2013

CHECK

CHECK

CHECK

Loading...

Loading...