62Y5A11

5-42

1

2

3

4

5

6

7

8

9

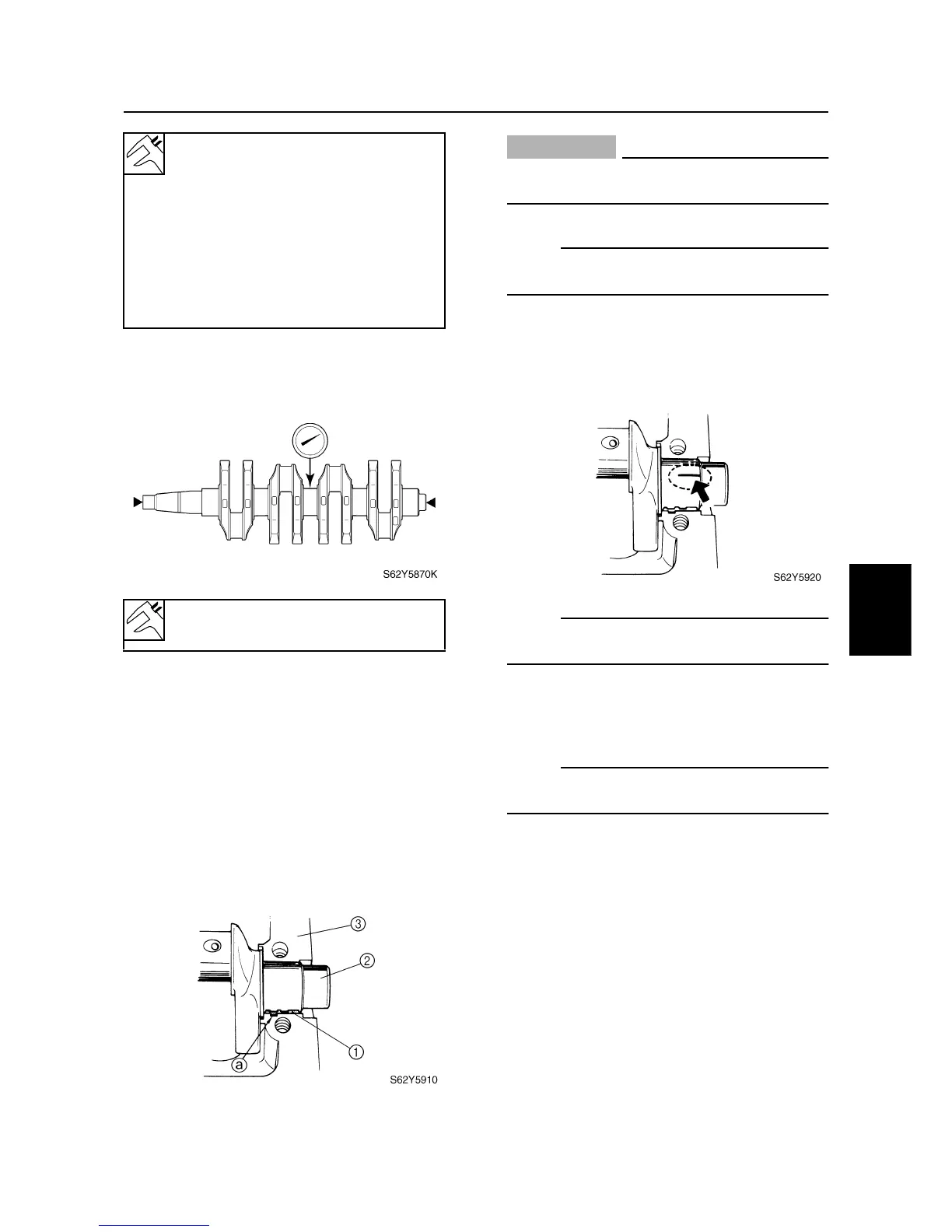

2. Measure the crankshaft runout. Replace

the crankshaft if out of specification.

Checking the crankshaft main

journal oil clearance

1. Clean the bearings, main journals, and

bearing portions of the crankcase and

cylinder body.

2. Place the cylinder body upside down on

a bench.

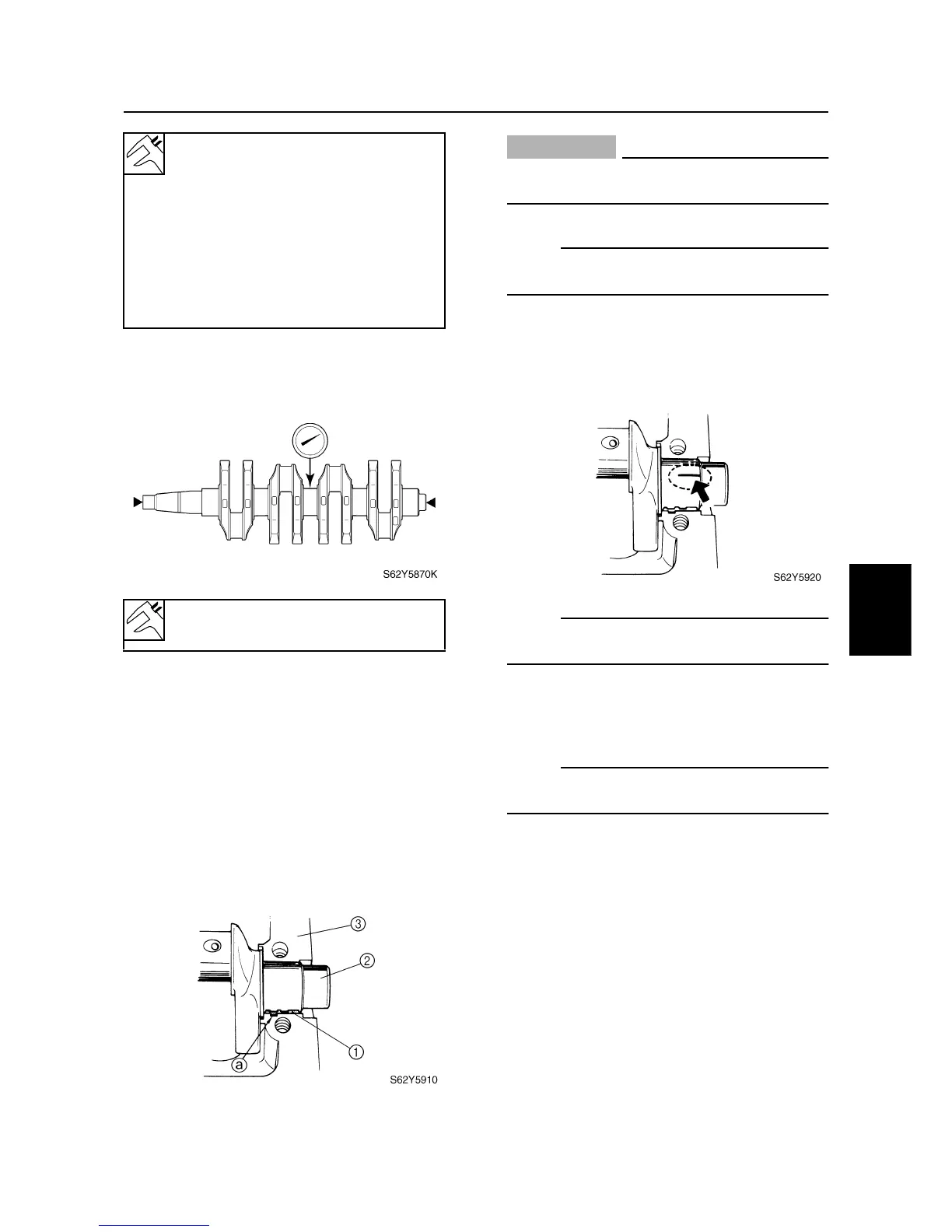

3. Install half of the bearings

1

and the

crankshaft

2

into the cylinder body

3

.

CAUTION:

Install the bearings in their original posi-

tions.

NOTE:

Insert the projection

a

of the bearing into the

notch in the cylinder body.

4. Put a piece of Plastigauge

®

(PG-1) on

each main journal parallel to the crank-

shaft.

NOTE:

Do not put the Plastigauge (PG-1) over the

oil hole in the main journals of the crankshaft.

5. Install the remaining half of the bearings

into the crankcase.

NOTE:

Insert the projection of the bearing into the

notch in the crankcase.

6. Install the crankcase onto the cylinder

body and apply engine oil onto the

threads of the crankcase bolts.

Crankshaft journal diameter

a

:

42.984–43.000 mm

(1.6923–1.6929 in)

Crank pin diameter

b

:

32.984–33.000 mm

(1.2986–1.2992 in)

Crank pin width

c

:

21.000–21.070 mm

(0.8268–0.8295 in)

Crankshaft runout limit:

0.04 mm (0.0016 in)

Cylinder body

Loading...

Loading...