8.2 Setup Procedure

8-9

8

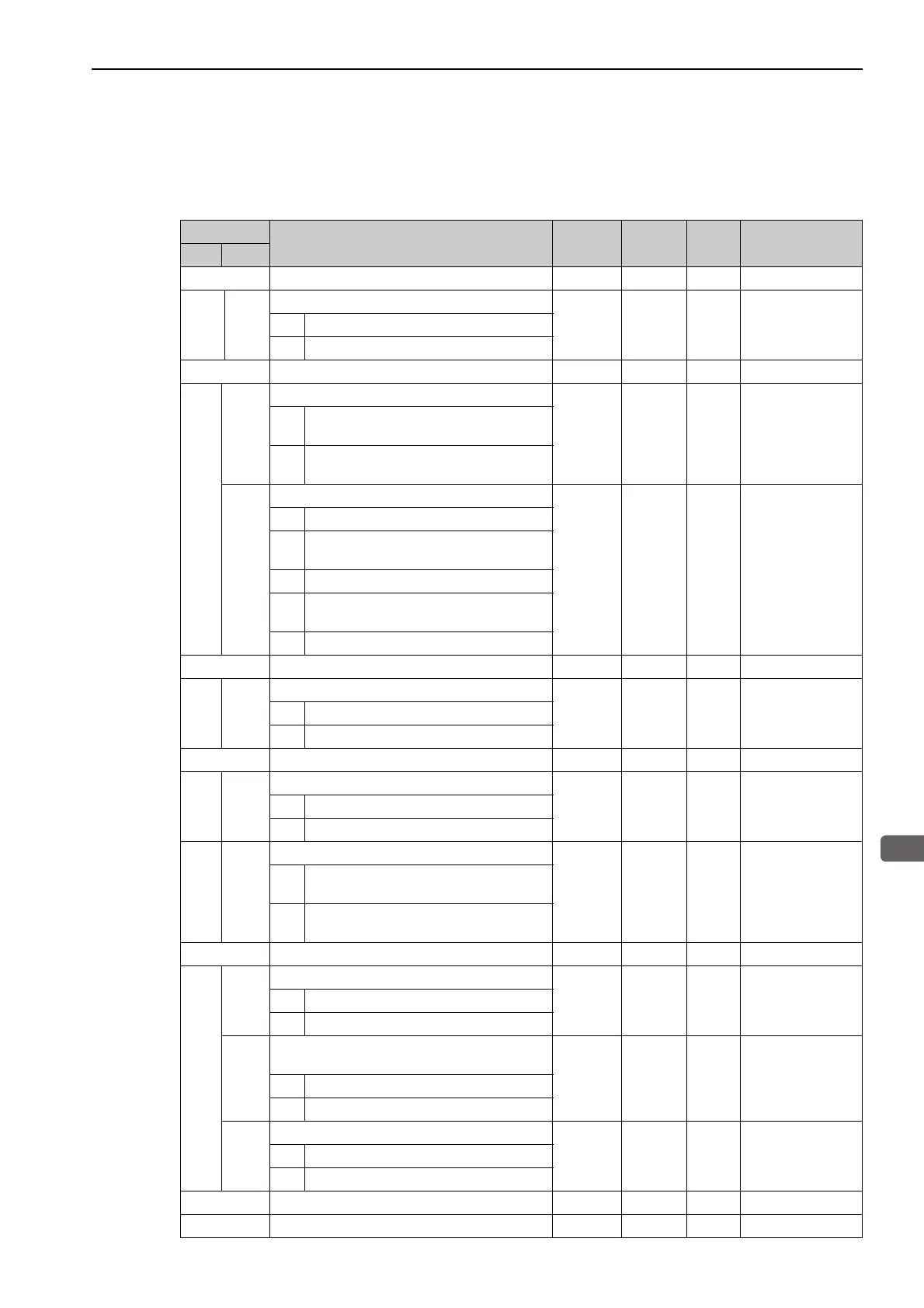

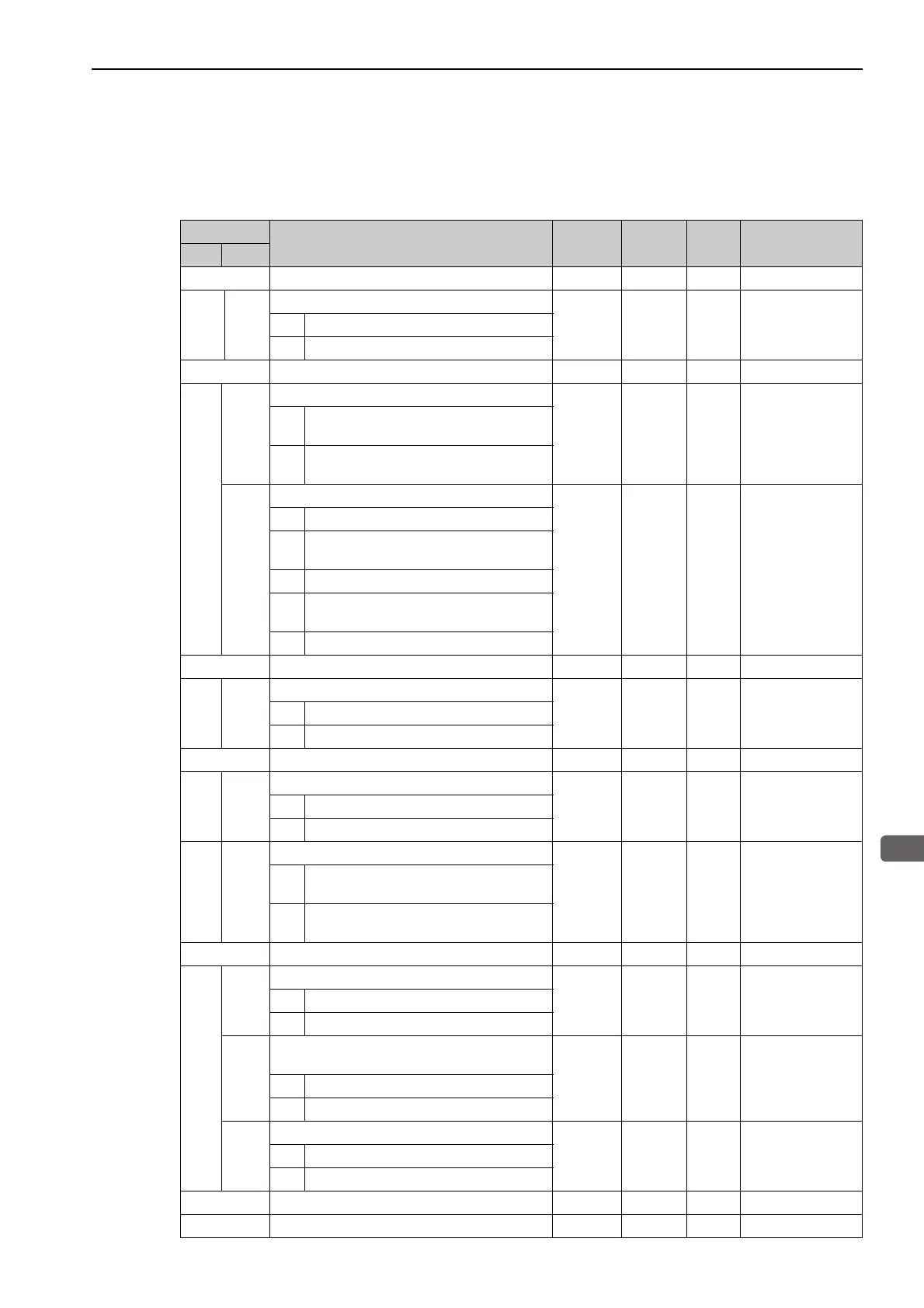

Set-up Procedure for Semi-closed Loop Control

8.2.2 Sigma-5 SERVOPACK Set-up with Rotary Motor

According to applications, these parameters should be set for the correct operation of Sigma-5 with the option

modules.

Parameter

Function

Default

Value

Required

value

Cat. When enabled

No. Dig.

Pn000 Basic Function Select Switch 0 - - - -

0

Direction Selection

0 *1 O After restart0 Forward command for forward direction

1 Forward command for reverse direction

Pn002 Application Function Select Switch 2 - - - -

2

Absolute Encoder Usage

0 *1 O After restart

0

Uses absolute encoder as an absolute

encoder

1

Uses absolute encoder as an incremental

encoder

3

External Encoder Usage

0 0 M After restart

0 Do not use external encoder

1

Uses external encoder in forward rotation

direction

2 Reserved (Do not change.)

3

Uses external encoder in reversed rotation

direction

4 Reserved (Do not change.)

Pn00B Application Function Select Switch B - - - -

3

Feedback Option Module Usage

0 *1 M After restart0 Used for external encoder feedback

1 Used for motor encoder feedback

Pn080 Application Function Select Switch B - - - -

0

Hall Sensor Selection

0 *1 O After restart0 Enables hall sensor

1 Disables hall sensor

1

Motor Phase Selection

0 *1 O After restart

0

Sets positive position feedback as phase

sequence of U, V, W

1

Sets negative position feedback as phase

sequence of U, V, W

Pn081 Application Function Select Switch 81 - - - -

1

Encoder Pulse Output Usage

0 *1 O After restart0 Enables the pulse output function (Pn281)

1 Disables the pulse output function

2

Coordination Setting between Origin and U-

phase position

0 *2 O After restart

0 Both positions are same

1 The positions are different

3

Hall Sensor Signal Inversion

0 *1 O After restart0 Does not inverse the signals (Pos-Logic)

1 Inverses the signals (Neg-Logic)

Pn212 Encoder Output pulses [Pulse/Rev] 2048 *1 O After restart

Pn481 Polarity Detection Speed Loop Gain [0.1 Hz] 40.0 *1 O Immediately

Loading...

Loading...