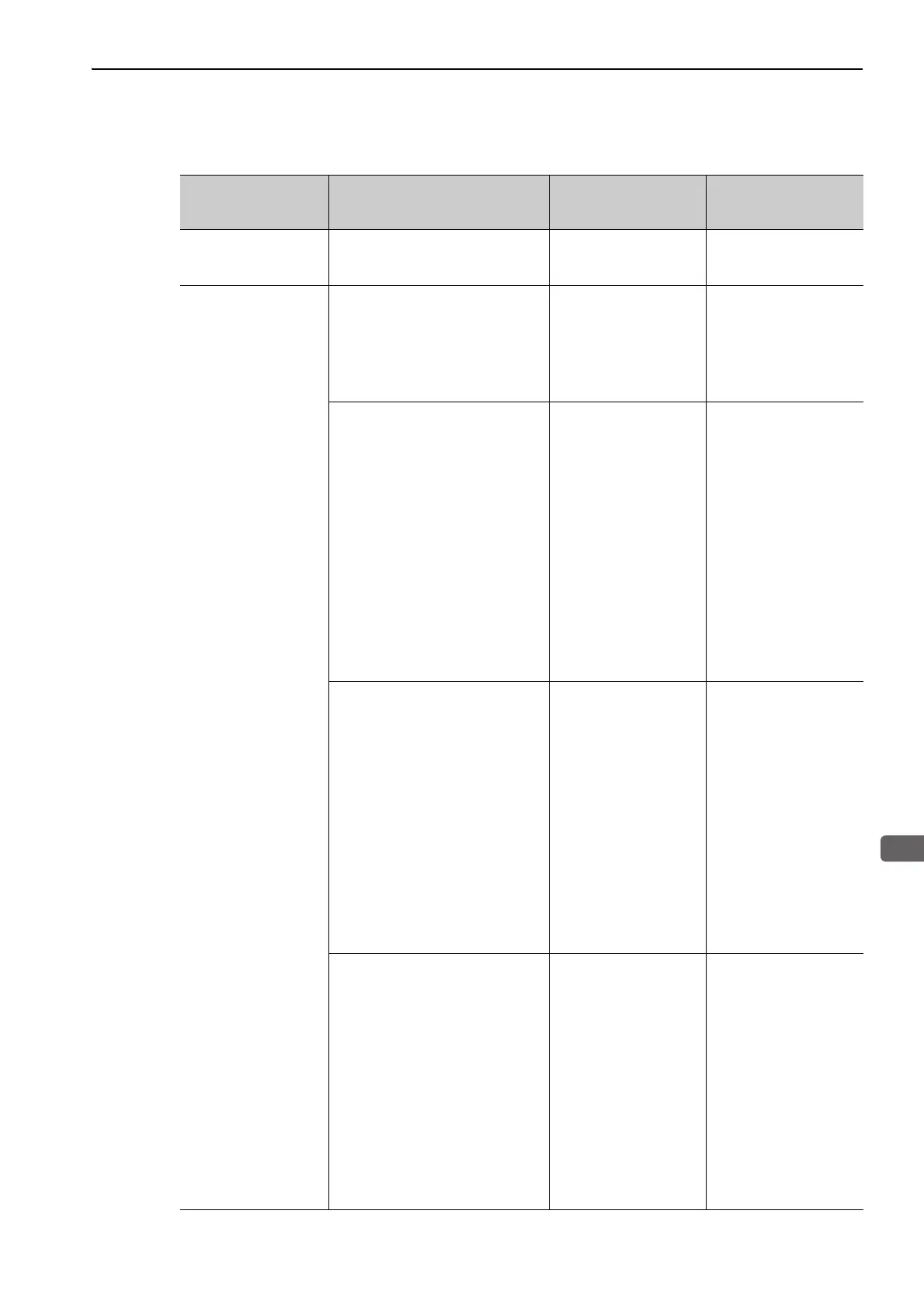

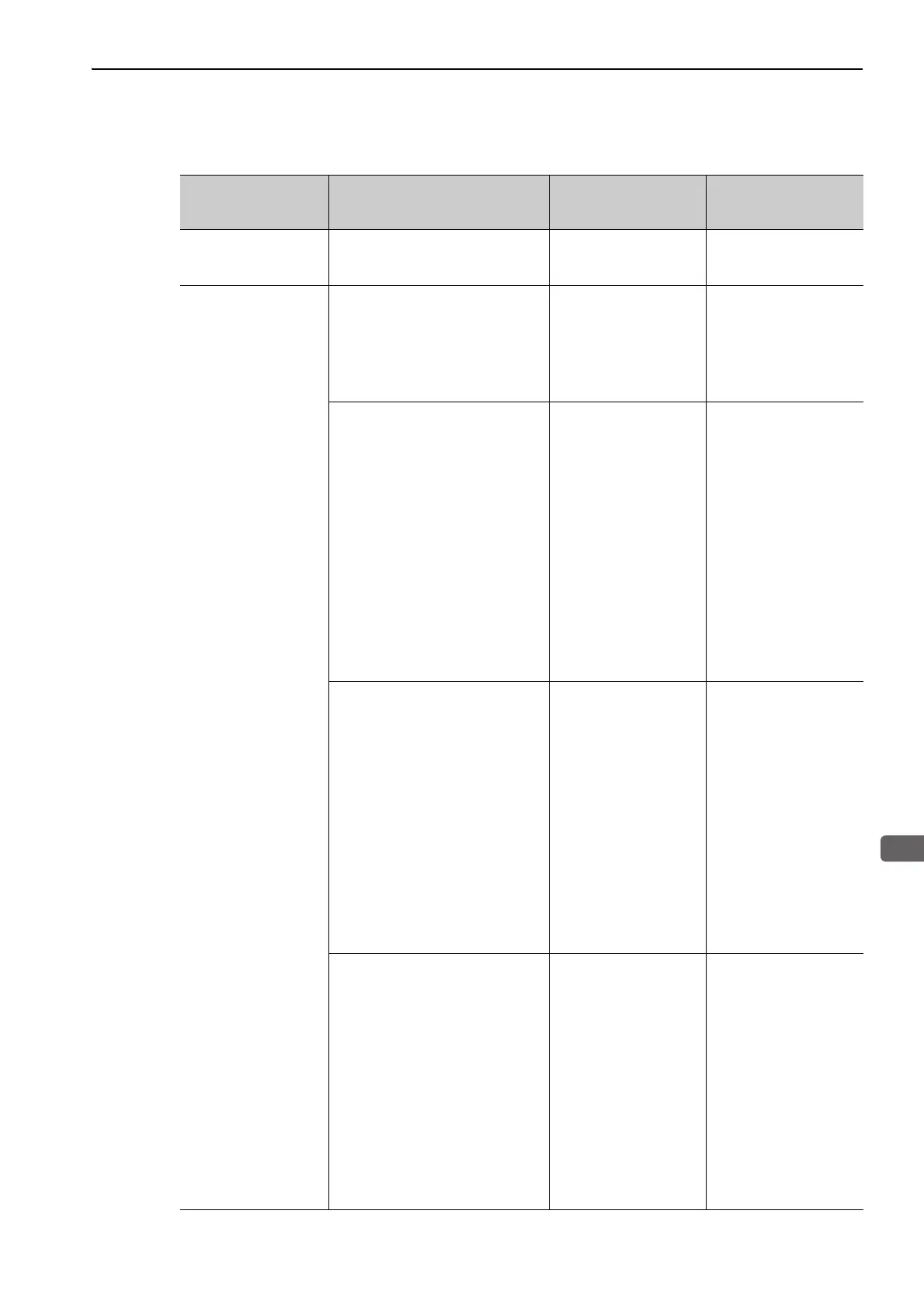

12.6 Errors during Pole Detection Functionality

12-9

12.6 Errors during Pole Detection Functionality

Alarm Number: Alarm

Name (Alarm

Description)

Cause Investigative Actions Corrective Actions

A.C22:

Pole Information Dis-

agreement

The SERVOPACK phase data does

not match that of the linear scale.

-

Execute polarity detec-

tion (Fn080).

A.C50:

Pole Detection Error

Parameter settings are incorrect.

Check the linear scale

specifications and feed-

back signal status.

The settings of the linear

scale pitch (Pn282) and

motor phase selection

(Pn080.1) may not match

the actual product require-

ments. Set these parame-

ters to the correct values

Noise interference occurred on the

scale signal.

Check the wiring to see if:

• Each FG of the serial

converter unit and lin-

ear servomotor is con-

nected to the FG of the

SERVOPACK.

• The FG of the SERVO-

PACK is connected to

the FG of the power

supply.

• The linear scale con-

nection cables are

securely shielded.

Check to see if the detec-

tion reference is repeat-

edly output in one

direction.

Take measures to avoid

noise interference by cor-

rectly connecting FG

lines, shielding the linear

scale connection cables,

etc.

An external force was applied to the

motor moving coil.

-

The polarity cannot be

properly detected if the

detection reference is 0

(zero), but the speed feed-

back is not 0 (zero)

because of an external

force, such as cable ten-

sion, applied to the motor

moving coil. Take mea-

sures to reduce the exter-

nal force so that the speed

feedback becomes 0 for a

0 detection reference. If

external force cannot be

reduced, increase the

polarity detection speed

loop gain (Pn481).

The linear scale resolution is too

low.

Check the linear scale

pitch to see if it is within

100 μm.

If the linear scale pitch is

100 μm or longer, the

SERVOPACK cannot

detect the correct speed

feedback. Use a scale

pitch with higher accuracy

(a pitch within 40 μm rec-

ommended.) Or, increase

the value of the polarity

detection reference speed

(Pn485). However, note

that increasing the value

of Pn485 will widen the

linear servomotor move-

ment range required for

polarity detection.

Loading...

Loading...