8 Set-up Procedure for Semi-closed Loop Control

8.2.3 Sigma-5 SERVOPACK Set-up with Linear Motor

8-10

*1 these settings are dependent on the applications

*2 in case of Pn080.0=1 (Disables hall sensor), the setting is not required

*3 this is only required when using Sigma-1 motors

8.2.3 Sigma-5 SERVOPACK Set-up with Linear Motor

According to applications, these parameters should be set for the correct operation of Sigma-5 with the option

modules.

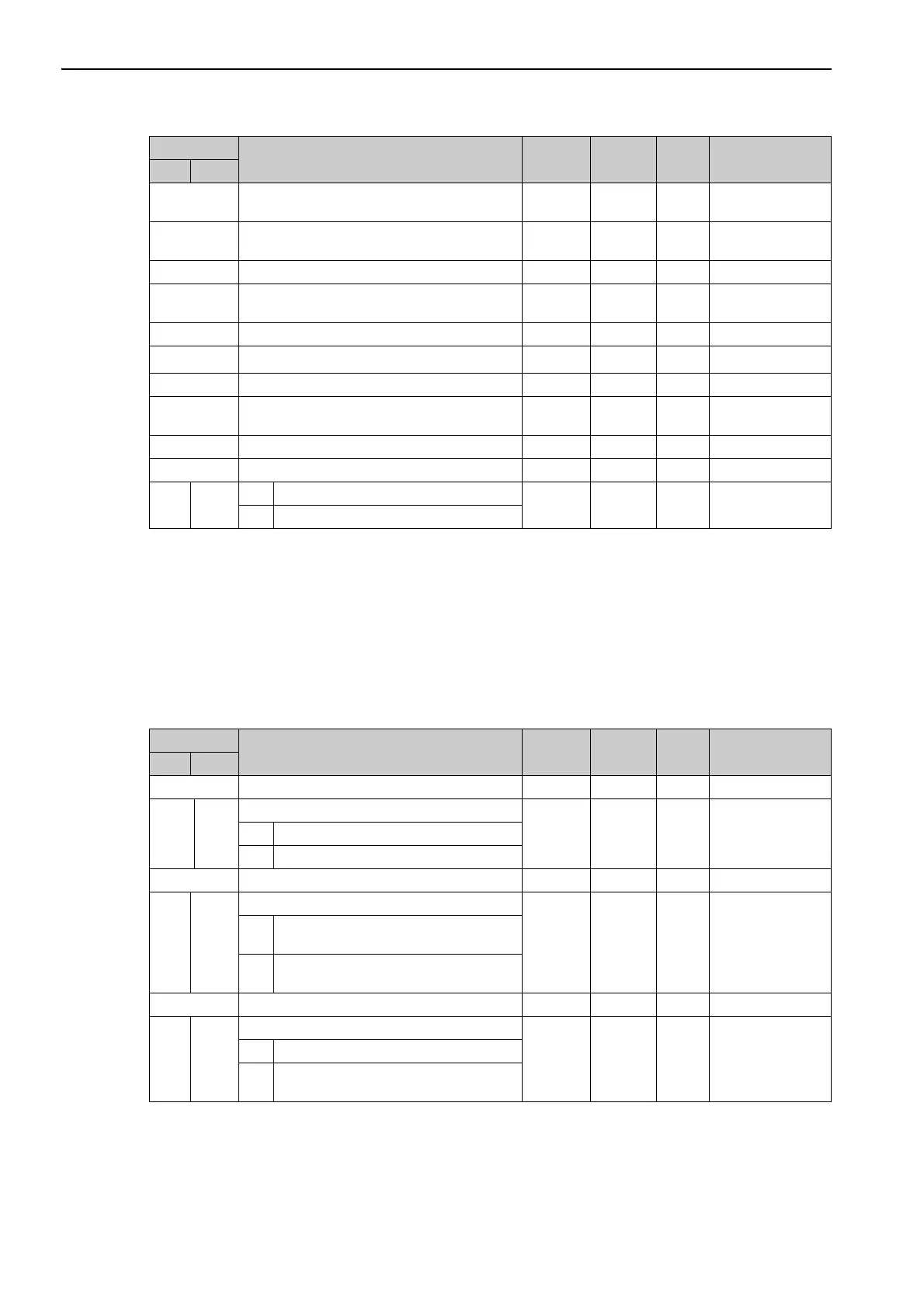

Pn482

Polarity Detection Speed Loop Integral Time

[0.01 msec]

30.00 *1 O Immediately

Pn486

Polarity Detection Command Accel/Decel Time

[msec]

25 *1 O Immediately

Pn487 Polarity Detection Constant Speed Time [msec] 0 *1 O Immediately

Pn488

Polarity Detection Command Waiting Time

[msec]

100 *1 O Immediately

Pn490 Polarity Detection Load Level [%] 100 *1 O Immediately

Pn493

Polarity Detection Command Speed [min

-1

]

50 *1 O Immediately

Pn494 Polarity Detection Range [0.001 rev] 0.250 *1 O Immediately

Pn495

Polarity Detection Confirmation Torque Com-

mand [%]

100 *1 O Immediately

Pn498 Polarity Detection Allowable Error Range [deg.] 10 *1 O Immediately

Pn587 Polarity Detection for Absolute Scale Selection - - - Immediately

0

0 Does not detect polarity

0 *1 O Immediately

1 Detects polarity

Parameter

Function

Default

Value

Required

value

Cat. When enabled

No. Dig.

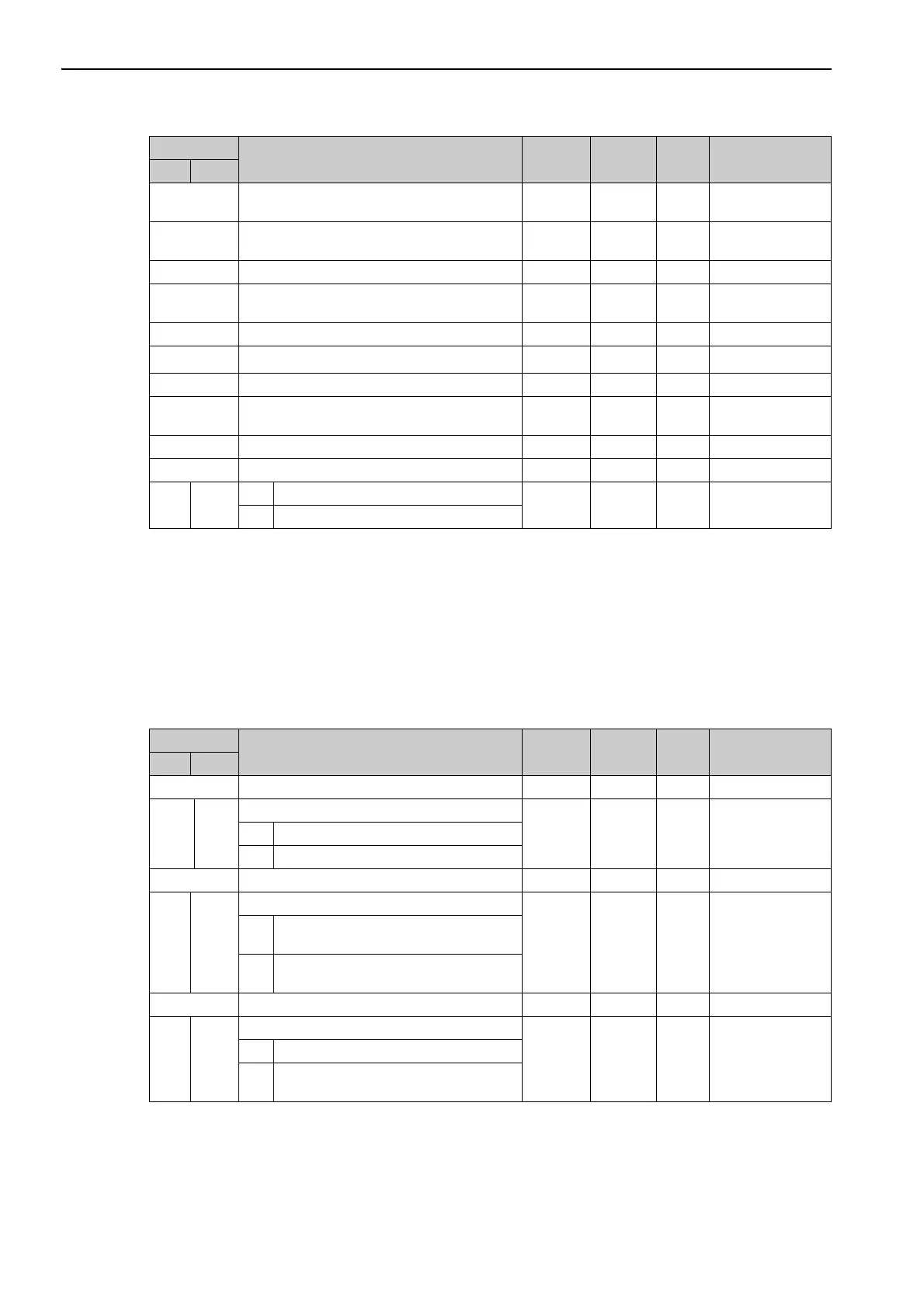

Parameter

Function

Default

Value

Required

value

Cat. When enabled

No. Dig.

Pn000 Basic Function Select Switch 0 - - - -

0

Direction Selection

0 *1 O After restart0 Forward command for forward direction

1 Forward command for reverse direction

Pn002 Application Function Select Switch 2 - - - -

2

Absolute Encoder Usage

0 *1 O After restart

0

Uses absolute encoder as an absolute

encoder

1

Uses absolute encoder as an incremental

encoder

Pn00B Application Function Select Switch B - - - -

3

Feedback Option Module Usage

0 *1 M After restart

0 Uses CN2 for external encoder feedback

1

Uses FB option for motor encoder feed-

back

Loading...

Loading...