Maintenance

114

Platen Cleaning and Replacement

The platen (drive roller) normally does not require cleaning. Paper and liner dust can accumulate without

affecting print operations.

Contaminants on the platen roller can damage the printhead or cause the media to slip or stick when

printing. Adhesive, dirt, general dust, oils and other contaminants should be cleaned immediately off the

platen.

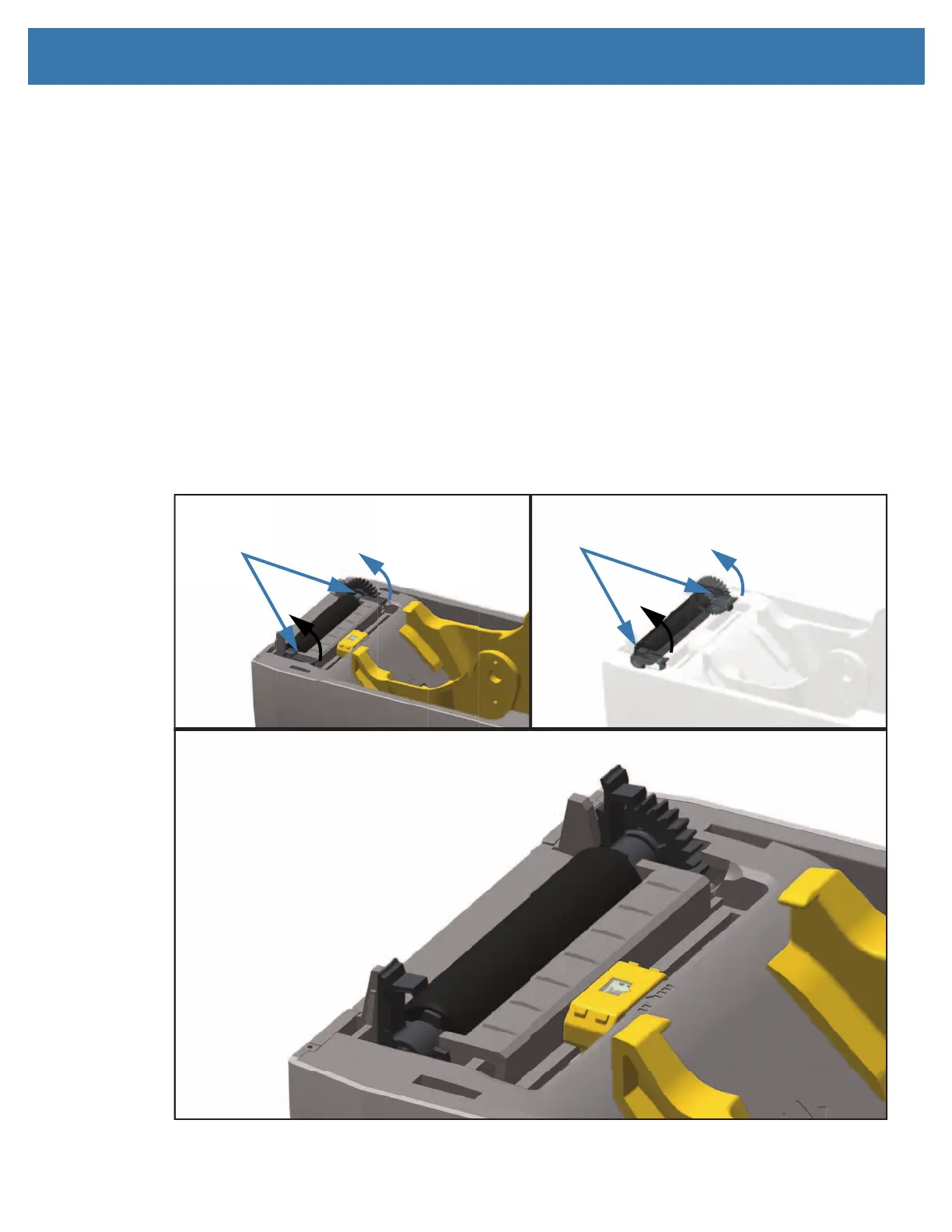

Clean the platen (and media path) whenever the printer has significantly poorer performance, print quality

or media handling. The platen is the print surface and drive roller for your media. If sticking or jamming

continues even after cleaning, you must replace the platen.

The platen can be cleaned with a fiber-free swab (such as a Texpad swab) or a lint free, clean, damp cloth

very lightly moistened with medical grade alcohol (90% pure or better).

1. Open the cover (and dispenser door if the dispenser is installed). Remove media from platen area.

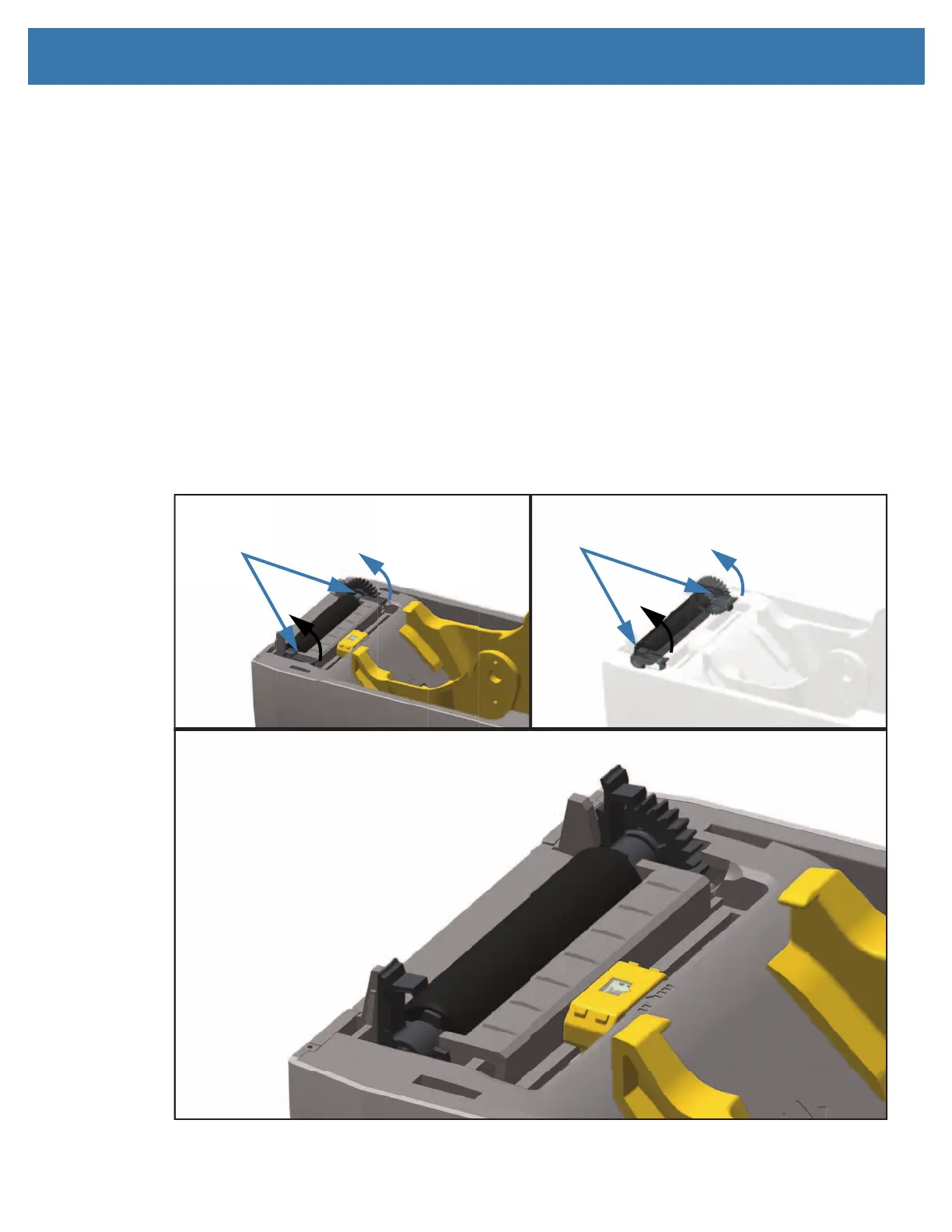

2. Pull the platen bearing latch release tabs on the right and left sides towards the front of the printer and

rotate them up.

Platen Bearings

Platen Bearings

Loading...

Loading...