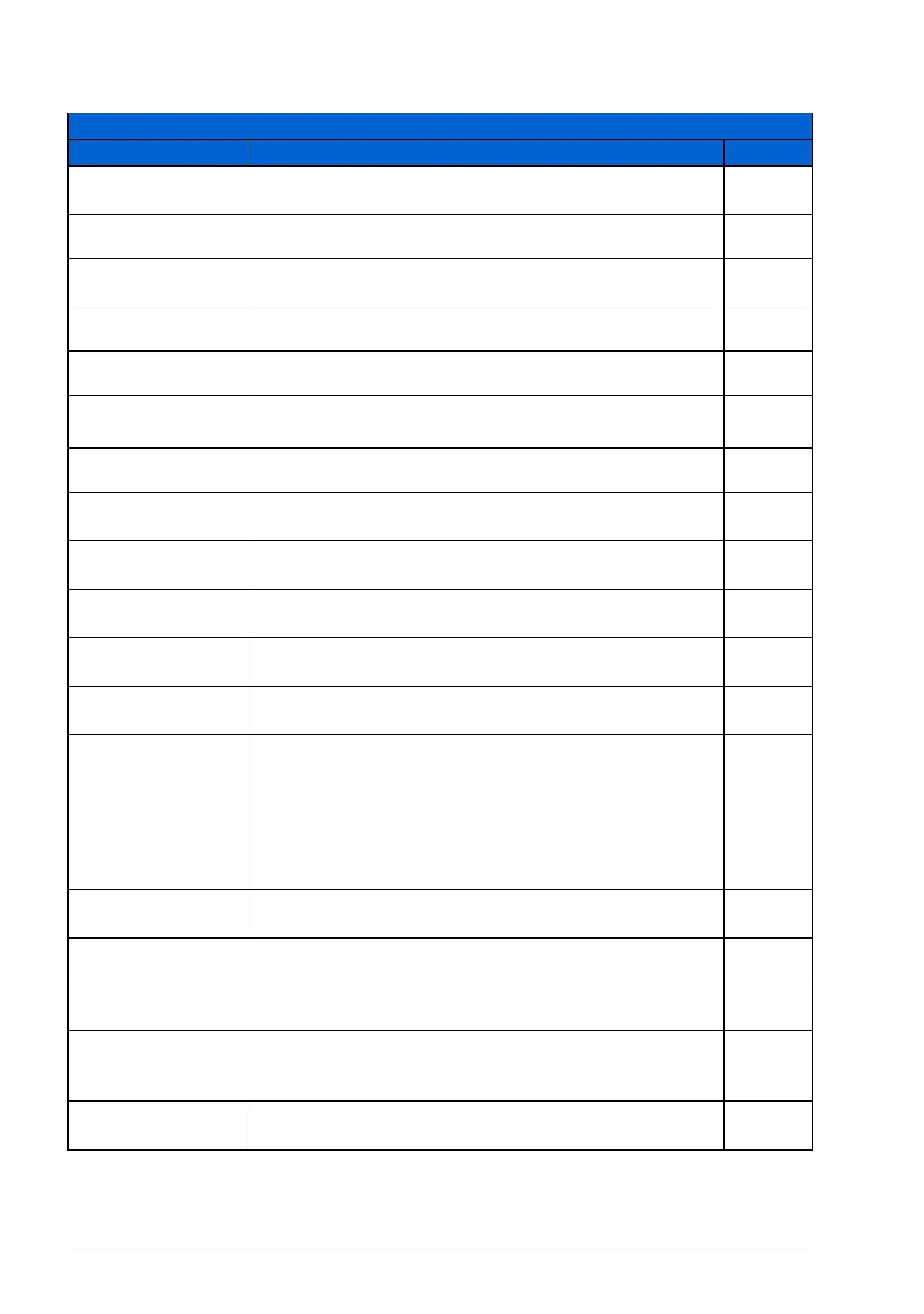

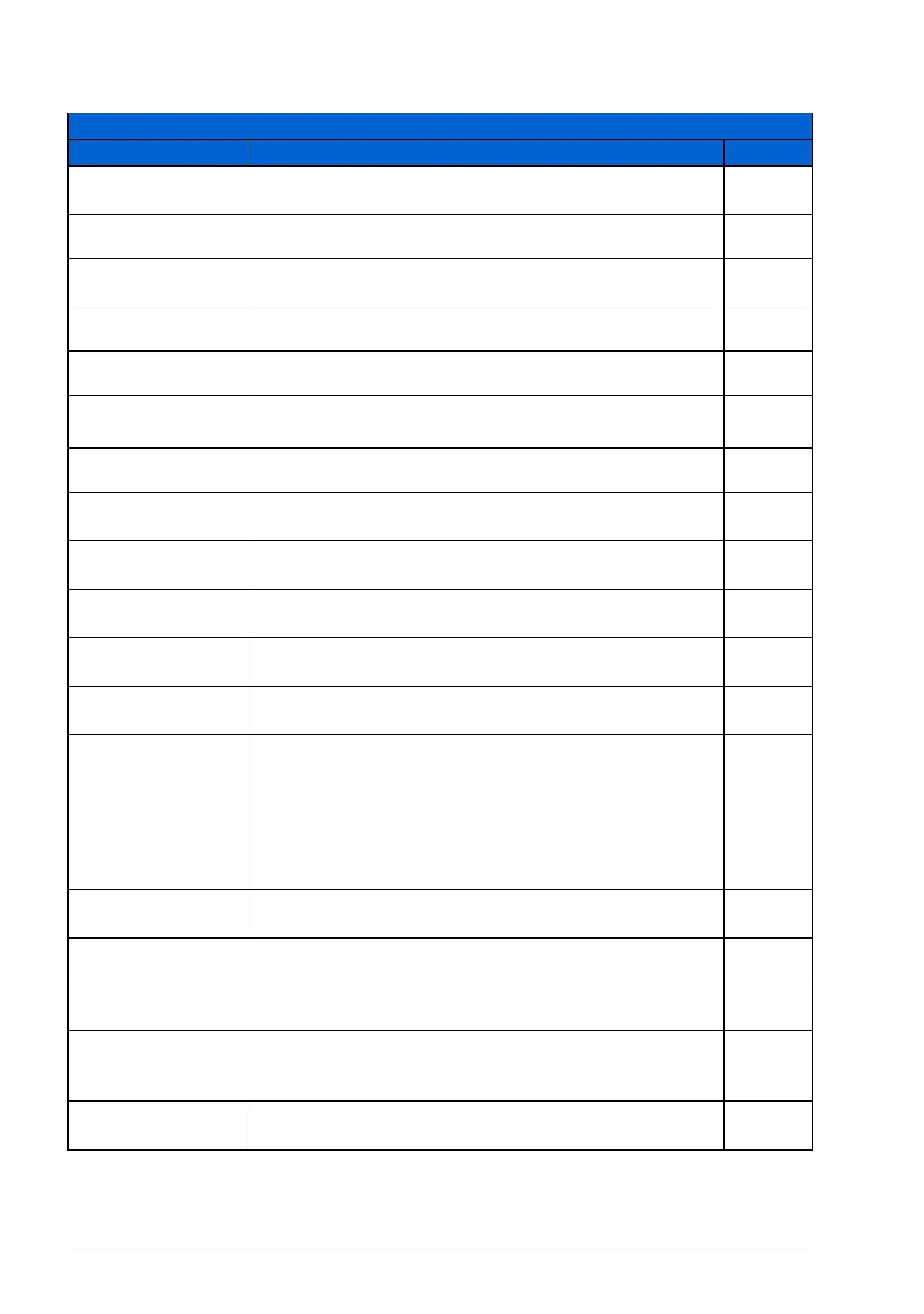

180 Actual signals and parameters

0147 MECH REVS Mechanical revolutions, ie the motor shaft revolutions

calculated by the encoder

1 = 1

0148 Z PLS

DETECTED

Encoder zero pulse detector. 0 = not detected, 1 = detected. 1 = 1

0150 CB TEMP Temperature of the drive control board in degrees Celsius

(0.0…150.0 °C).

1 = 0.1 °C

0158 PID COMM

VALUE 1

Data received from fieldbus for PID control (PID1 and PID2) 1 = 1

0159 PID COMM

VALUE 2

Data received from fieldbus for PID control (PID1 and PID2) 1 = 1

0160 DI 1-5 STATUS Status of digital inputs.

Example: 10000 = DI1 is on, DI2…DI5 are off.

0161 PULSE INPUT

FREQ

Value of frequency input in Hz 1 = 1 Hz

0162 RO STATUS Status of relay output 1. 1 = RO is energized, 0 = RO is de-

energized.

1 = 1

0163 TO STATUS Status of transistor output, when transistor output is used as

a digital output.

1 = 1

0164 TO

FREQUENCY

Transistor output frequency, when transistor output is used

as a frequency output.

1 = 1 Hz

0165 TIMER VALUE Timer value of timed start/stop. See parameter group 19

TIMER & COUNTER.

1 = 0.01 s

0166 COUNTER

VALUE

Pulse counter value of counter start/stop. See parameter

group 19 TIMER & COUNTER.

1 = 1

0167 SEQ PROG

STS

Status word of the Sequence programming:

Bit 0 = ENABLED (1 = enabled)

Bit 1 = STARTED

Bit 2 = PAUSED

Bit 3 = LOGIC VALUE (logic operation defined by

parameters 8406…8410).

1 = 1

0168 SEQ PROG

STATE

Active state of the Sequence programming. 1…8 = state

1…8.

1 = 1

0169 SEQ PROG

TIMER

Current state time counter of the Sequence programming 1 = 2 s

0170 SEQ PROG AO

VAL

Analog output control values defined by the Sequence

programming. See parameter 8423 ST1 OUT CONTROL.

1 = 0.1%

0171 SEQ CYCLE

CNTR

Executed sequence counter of the Sequence programming.

See parameters 8415 CYCLE CNT LOC and 8416 CYCLE

CNT RST.

1 = 1

0172 ABS TORQUE Calculated absolute value of the motor torque in percent of

the motor nominal torque

1 = 0.1%

Actual signals

No. Name/Value Description FbEq

Loading...

Loading...