■ Connection procedure of the brake chopper cubicle

WARNING!

Obey the safety instructions of the drive. If you ignore them, injury or death, or

damage to the equipment can occur.

If you are not a qualified electrical professional, do not do installation or

maintenance work.

1.

Stop the drive and do the steps in section Electrical safety precautions (page 50) before

you start the work.

2. Make the internal connections of the brake chopper cubicle. See the diagram above.

■ Connection procedure of the resistor cables

WARNING!

Obey the safety instructions of the drive. If you ignore them, injury or death, or

damage to the equipment can occur.

If you are not a qualified electrical professional, do not do installation or

maintenance work.

1.

Stop the drive and do the steps in section Electrical safety precautions (page 50) before

you start the work.

2. Open the door of the brake unit cubicle and remove the shrouding.

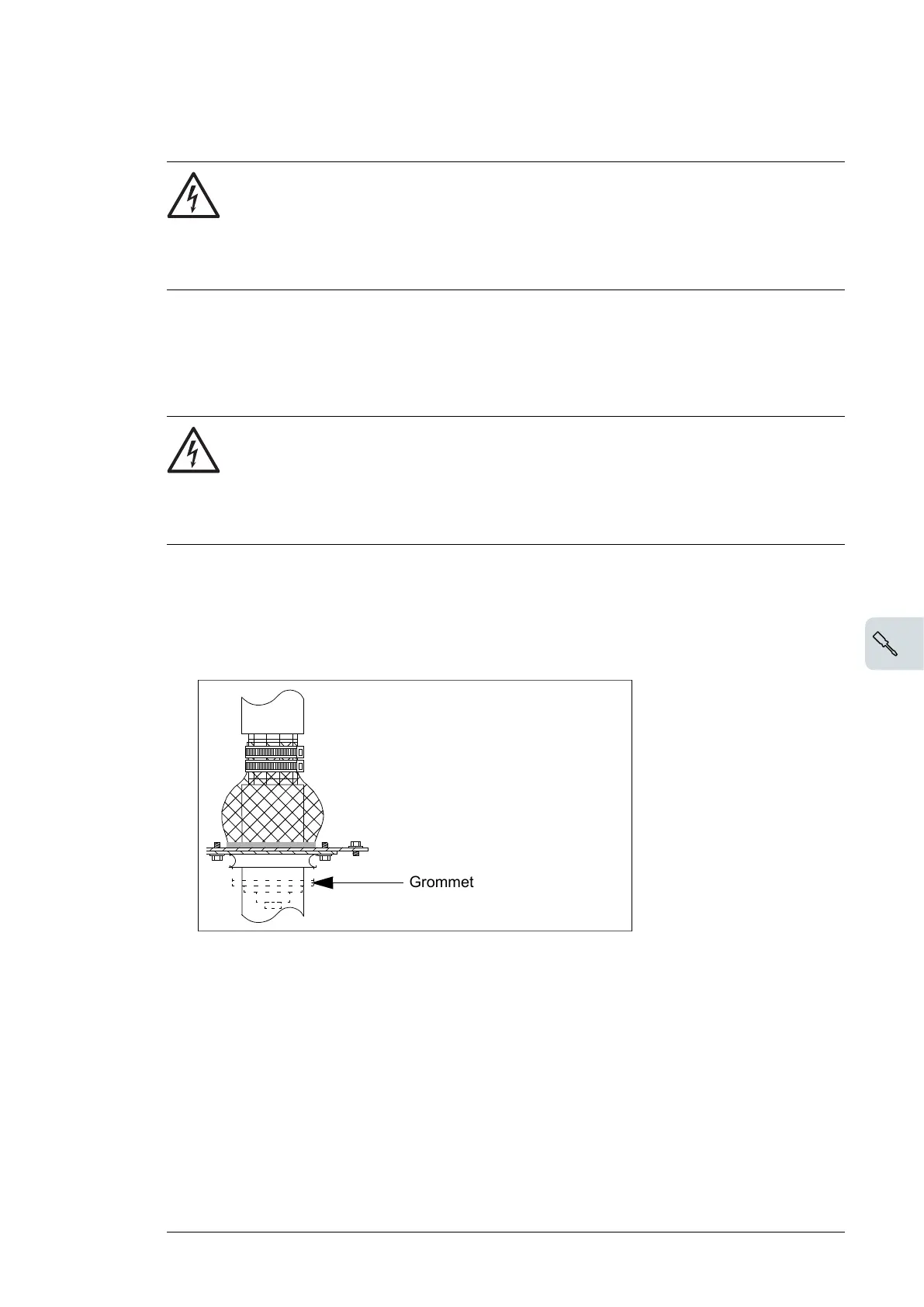

3. Lead the cables into the cubicle. Make the 360° earthing arrangement at the cable entry

as shown. Install the rubber grommet (if present) below the cable entry for proper sealing.

118 Electrical installation

3. Lead the cables into the cubicle. Make the 360° earthing arrangement at the cable

entry as shown.

4.

Cut the cables to suitable length. Strip the cables and conductors.

5. Twist the cable screens into bundles and connect the bundles to the PE busbar in th

e

cubicle.

6.

Connect any separate ground conductors/cables to the PE busbar in the cubicle.

7. Connect the phase conductors to the output terminals. Use the torques specified

under Tightening torques (page 199).

8. Refit any shrouding removed earlier and close the cubicle doors.

9. At the motor, connect the cables according to instructions from the

motor

manufacturer

. Pay special attention to the phase order. For minimum radio-frequen

cy

in

terference, ground the cable shield 360 degrees at the lead-through of

the motor

terminal box,

or ground the cable by twisting the shield so that the flatten

ed shield is

wider than

1/5 of its length.

Connecting an external brake resistor assembly

See section Electrical installation of custom brake resistors (page 267).

For the location of the terminals, refer to the dimension drawings delivered with the unit or

the dimension drawing examples in chapter Dimensions.

4. Cut the cables to suitable length. Strip the cables and conductors.

5. Twist the cable shields into bundles and connect the bundles to the PE busbar in the

cubicle.

6. Connect the resistor cables. Note the connection of the third conductor and the cable

shield. See also the circuit diagrams delivered with the unit. See the technical data for

tightening torques.

Electrical installation 53

Loading...

Loading...