NoteAction

Used belt: 315Use a sonic tension meter to measure the timing

belt tension.

8

New belt:260

If the timing belt tension does not meet the require-

ment, loosen the motor screws and readjust.

9

Screws: Hex socket head cap

screw M4x10 12.9 Lafre

2C2B/FC6.9 (3 pcs)

Refit the pulley protection cover and secure with

screws.

10

Tightening torque: 0.8 Nm

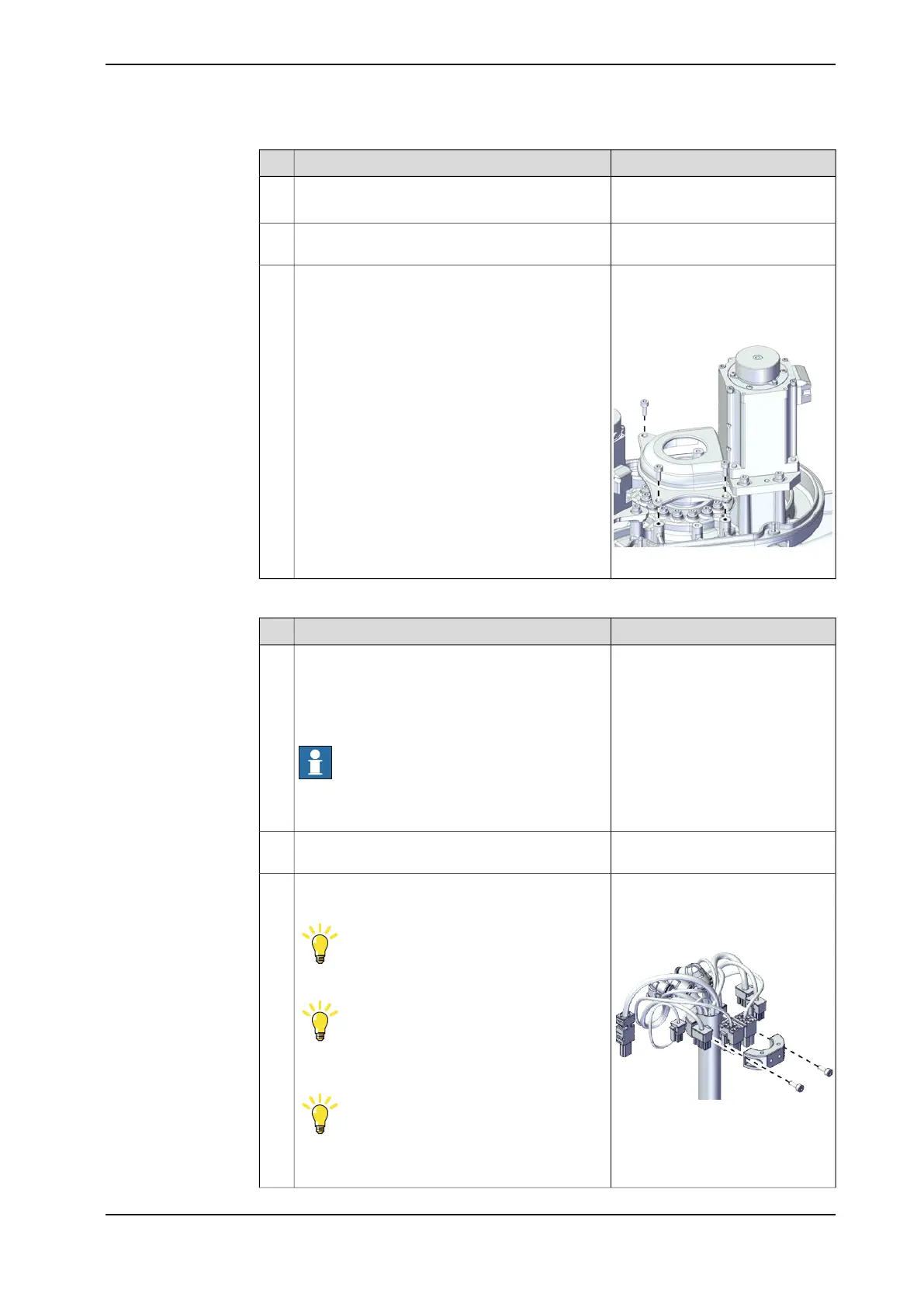

xx2100001047

Refitting the cable ferrule and bracket in the outer arm

NoteAction

For robots with protection type Clean Room:1

Clean the joints that have been opened and wipe

the parts free from particles with spirit on a lint

free. See Cut the paint or surface on the robot

before replacing parts on page 118

Note

After all repair work, wipe the Clean Room robot

free from particles with spirit on a lint free cloth.

Lay the internal harness in a natural state without

distortion.

2

Screws: Hex socket head cap

screw M3x8 12.9 Lafre 2C2B/FC6.9

(2 pcs)

Refit the cable ferrule and secure it with the

screws.

Tip

The air hoses should face the process hub side.

3

Tightening torque: 1.2 Nm ±10%

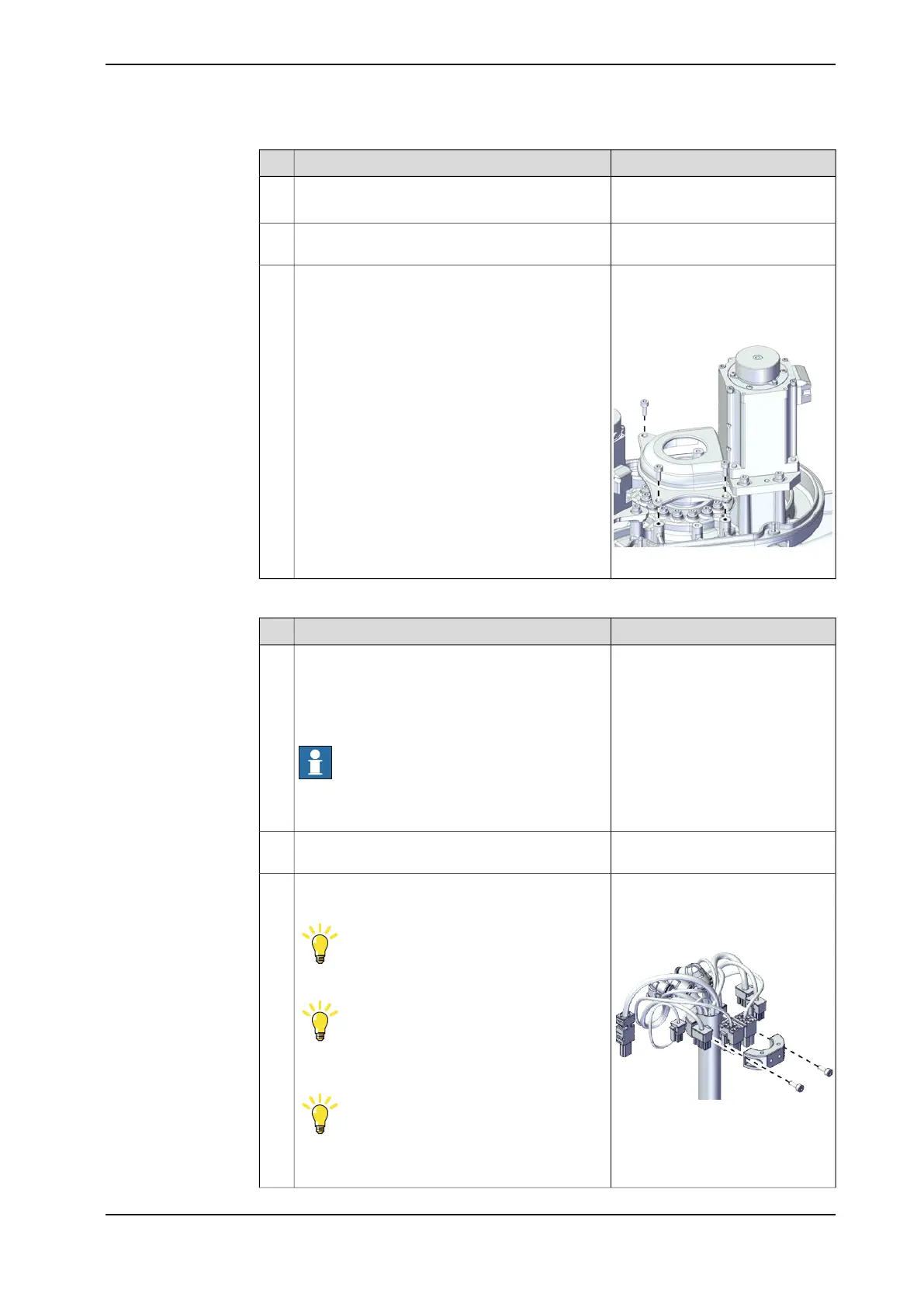

xx1800002849

Tip

The position with wrapped tape is the marked

position for the cable ferrule.

Tip

Align all the cable ferrules so that the cable is in

a natural bending position to avoid twisting.

Continues on next page

Product manual - IRB 920 789

3HAC075721-001 Revision: C

© Copyright 2022 ABB. All rights reserved.

5 Repair

5.7.2 Replacing the axis-2 motor sub-assembly

Continued

Loading...

Loading...