Doc : AM220-001E Release: 1.5 updated : October 2014

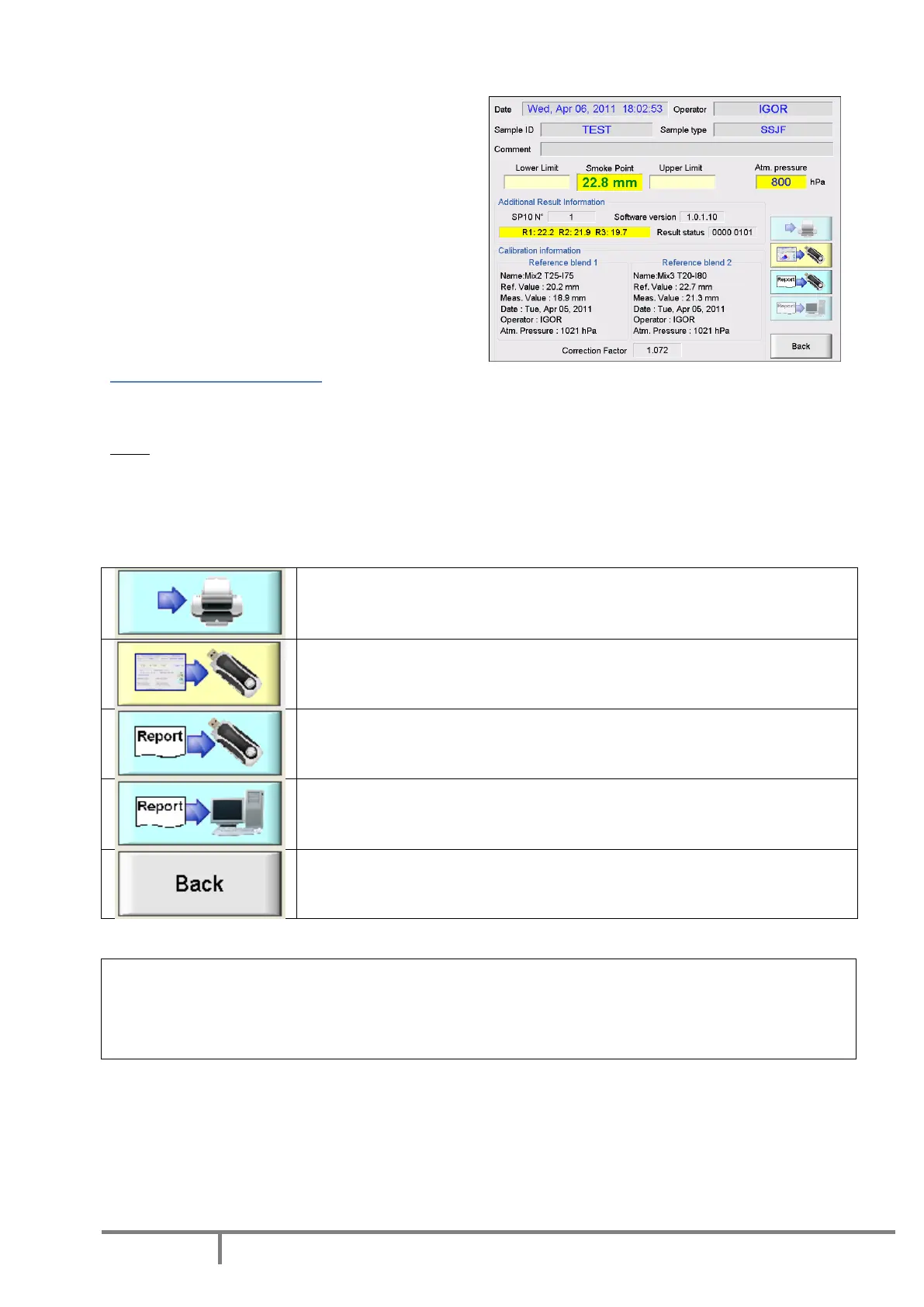

In this example, the barometric pressure is much different to the best matching pressure found in

calibration database. In addition, there is a problem

in 3 readings. One result is significantly (more than

1 mm) different compared with the 2 others.

In that particular case, when the Result Status is not

zero, the operator is in charge of accepting or not

the reported result.

The Result Status is included in the ASCII test report

sent to the LAN. It can be used for automatic

acceptance of the test result into LIMS.

Calibration information

This information contains details about the pair of reference fuels that have been used to calculate lamp

factor for this test. Resulting calibration factor is displayed for traceability.

Note: The instrument calibration information can be included in the ASCII test report file. To do so, use

report type 2 (for more details please refer to “Test data storage” in this manual).

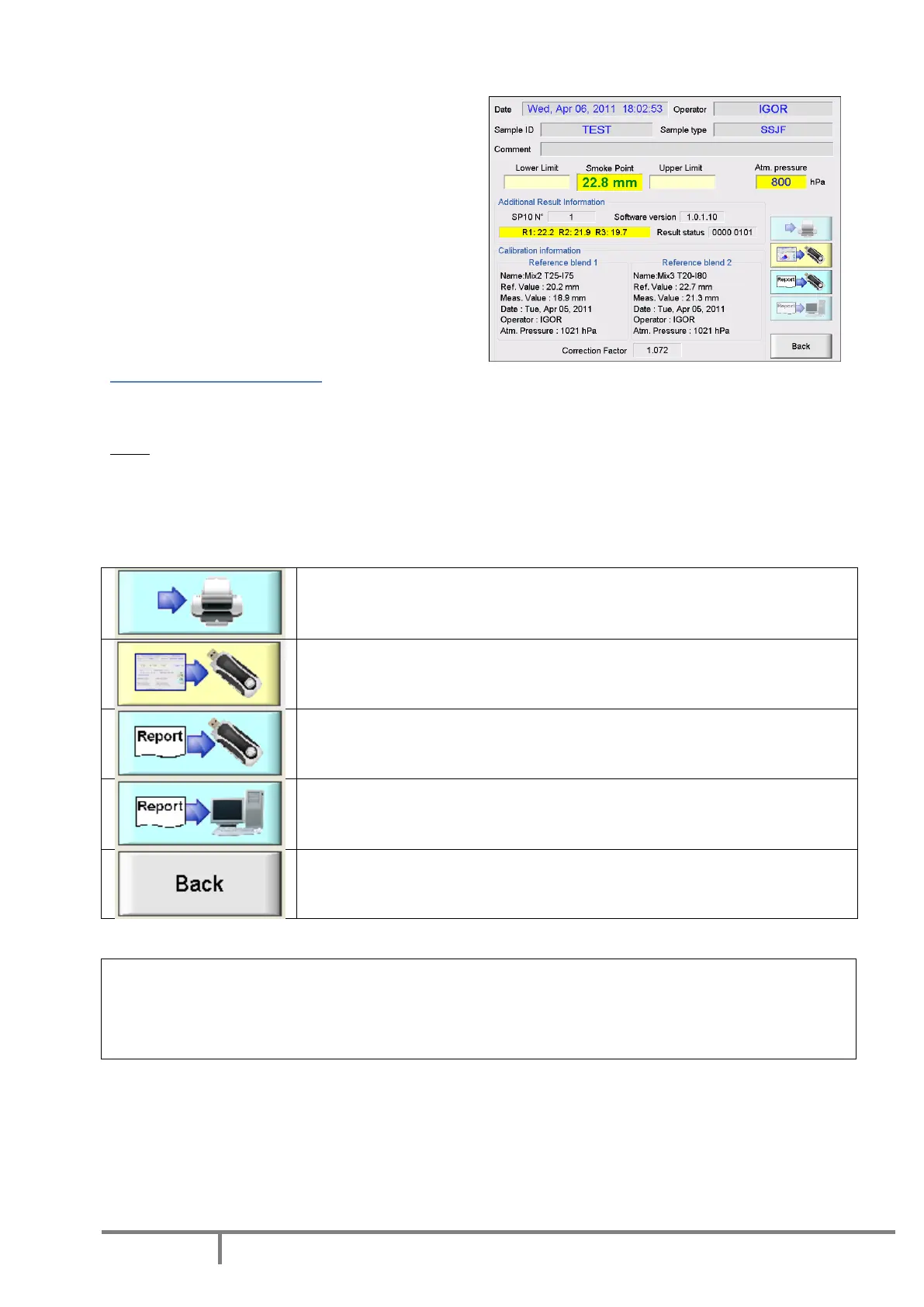

Control buttons

Control buttons on the result screen provides versatile reporting options.

To print the result with the optional printer

To save the snap shot of the report screen on a USB storage device (the

button is activated when USB storage device is connected)

To save the test report in ASCII format on a USB storage device (the button

is activated when USB storage device is connected)

To send the test report in ASCII format to LAN (the button is activated when

the SP 10 is connected to a LAN)

To return to the Main Menu or get access to search result database

CAUTION! The SP 10 automatically detects the USB drive as soon as it is connected. If the drive capacity is

important, its detection could take a few seconds. Consequently it is highly recommended not to connect

the USB storage device during test progress. It could interfere with the measurement and an error

message could appear.

Loading...

Loading...