ADTECH9 Series CNC Programming Manual

2.3.4. Notes for tool radius compensation

(1) Specifying the compensation

The compensation is specified by D instruction and compensation No. Once D instruction is specified, this

instruction is always valid until new D instruction is specified. P170 error will occur if specified with H

instruction.

In addition to specifying the compensation of tool radius compensation, D instruction also can be used as the

compensation value of tool position compensation.

(2) Changing compensation

The compensation is usually changed after radius compensation mode is canceled and another tool is selected;

in compensation mode, when the compensation is changed, the vector of segment end point is calculated

according to the compensation specified by the segment.

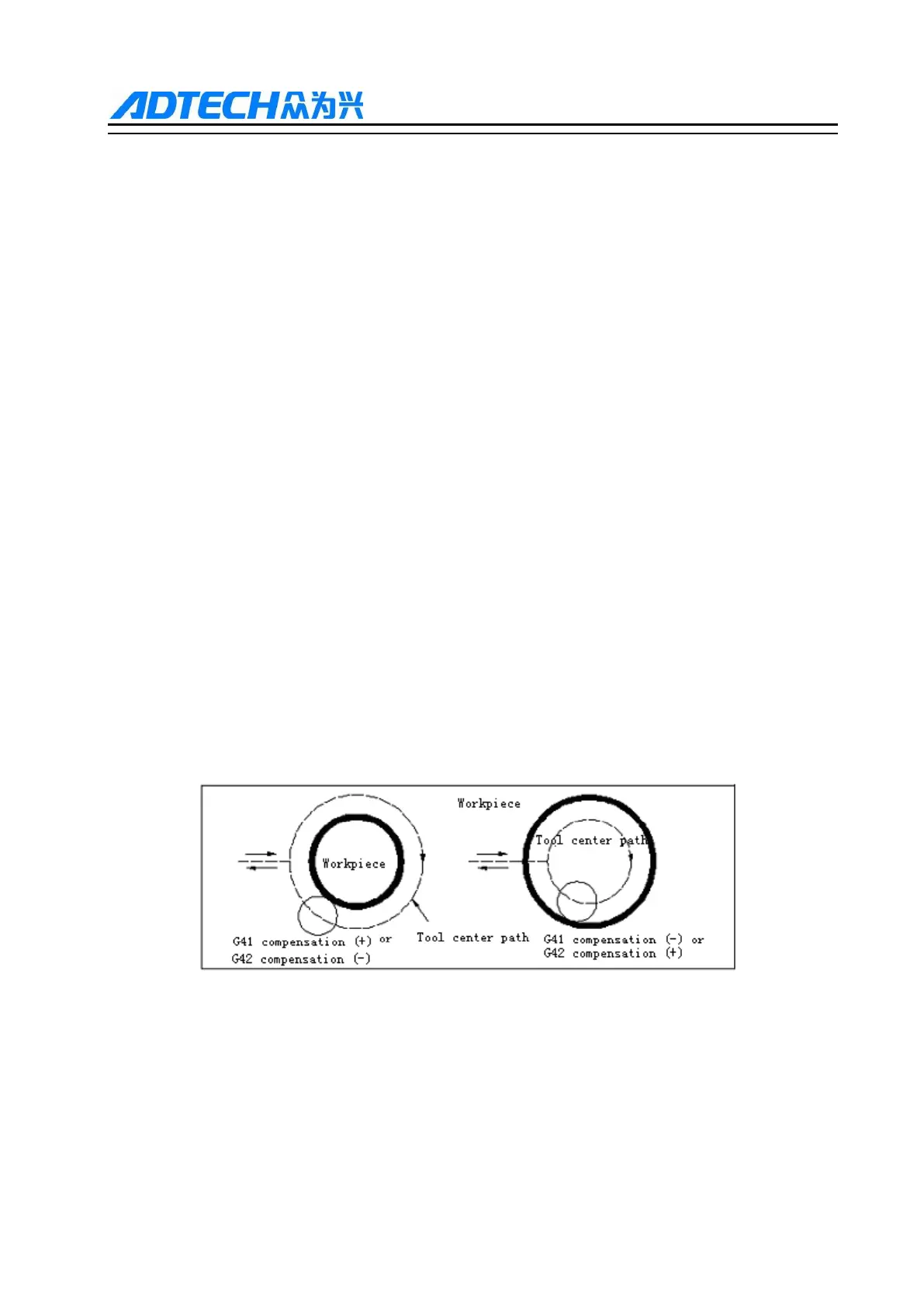

(3) Compensation symbol and tool center path

If the compensation is negative (-), it is same to G41 and G42 switched circles; but the rotation outside of

workpiece turns into inside rotation, and the inside rotation turns into outside rotation.

Generally, the compensation is made into program with positive (+) symbol. In the figure below, the tool

center path in the left will be as in the right if the compensation turns to negative. Therefore, the processing

shown in the figure below only needs to select the tolerance of them, adds in appropriate compensation, and

then cut into two shapes with one program.

Loading...

Loading...