ADTECH9 Series CNC Programming Manual

next segment. The distance of every feeding is specified by hole processing parameter Q, which is

always positive; the value of d is specified by 532# machine tool parameters.

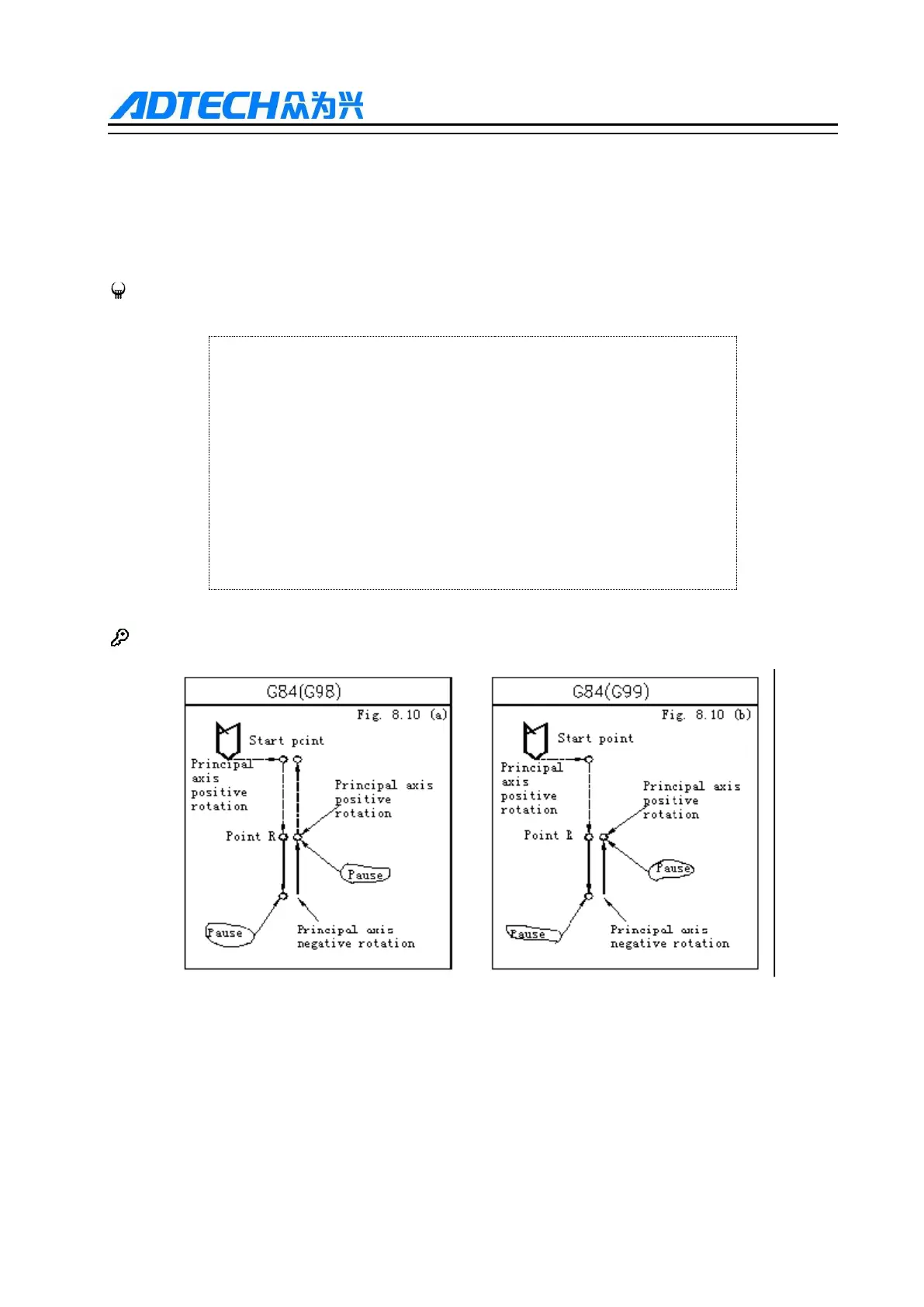

2.4.7. Tapping cycle (G84)

Format:

G84 X_ Y_ Z_ R_ P_ F_(D_)

X_Y_ :thread position

Z_ :threaded hole bottom position

R_ :point of tool feeding /retreating

P_ :Dwell time at the bottom of hole

F_(D_) :convert to the feeding speed according to screw distance, or

specify the screw distance with D_ directly

K_ :repeat times (if necessary)

Details:

Taping Cycle Diagram

The sequence of actions is as follows:

1. Quickly locate it to the hole (X Y, but the tool maintains the original height)

2. Quickly locate it to point R

3. Tapping starts, and spindle reverses

4. Cut to the bottom position of the hole (Z) with the set cutting feedrate and spindle speed

5. Spindle stops; if P is specified, it pauses at hole bottom (P) ms

Loading...

Loading...