ADTECH9 Series CNC Programming Manual

retraction amount (mm), and the depth of every feeding is determined by hole processing parameter Q.

This fixed cycle is mainly used for processing holes with small diameter/depth ratio (e.g. Φ5, depth 70), and Z

axis lift has the effect of chip breaking after cutting and feeding every segment.

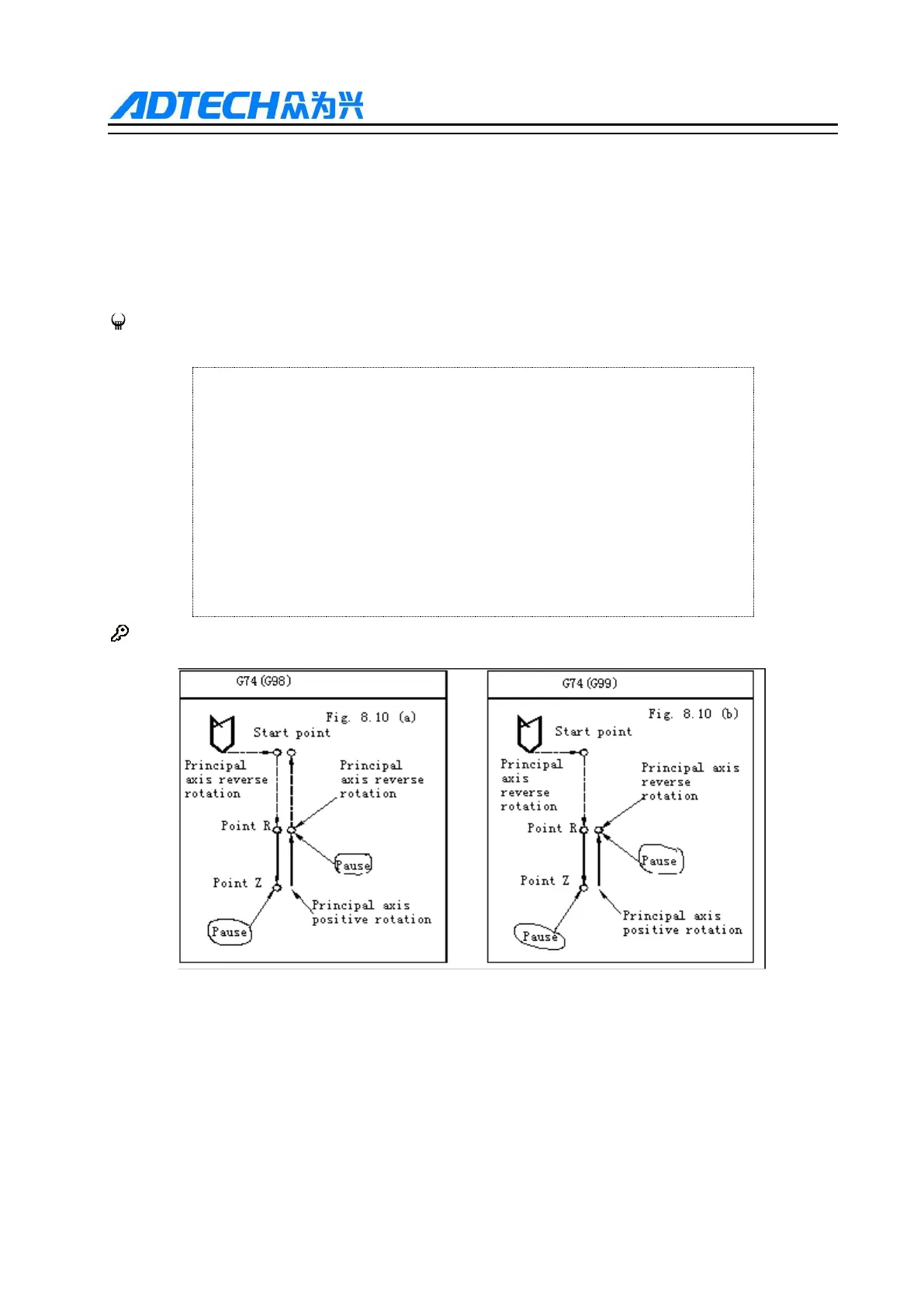

2.4.2. Left-hand Thread tapping cycle (G74)

Format:

Format G74 X_ Y_ Z_ R_ F_(D_)

X_Y_ :thread position

Z_ :Threaded hole bottom position

R_ :point of tool feeding/ retreating

P_ :Dwell time at the bottom of hole

F_(D_) :convert to feeding speed according to screw distance, or specify the

distance with D

K_ :repeat times (If necessary)

Details:

Left-hand Thread Taping Cycle Diagram

The sequence of actions is as follows:

Quickly locate it to the hole (X Y, but the tool maintains the original height)

Quickly locate it to point R

Tapping starts, and spindle reverses

Cut to the bottom position of the hole (Z) with the set cutting feedrate and spindle speed

Loading...

Loading...