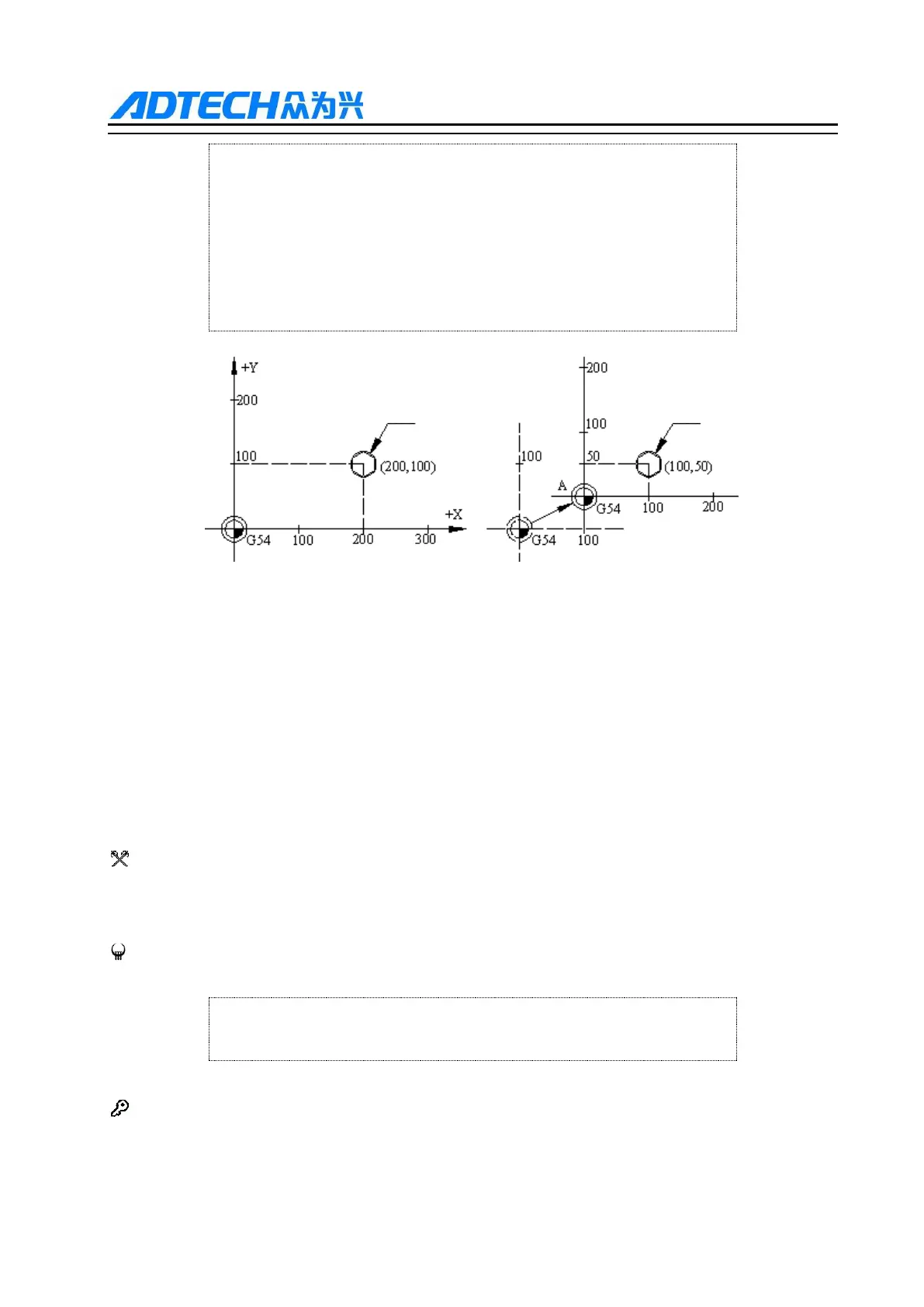

The origin of new coordinate system offsets to the position A in the lower

right figure;

The offset of coordinate system is (100, 50), (the difference between the

coordinates of the tool in original coordinate system and IP_ instruction

value).

The coordinates of the tool in new coordinate system are (100, 50).

G92 Instruction Function Diagram

2.2

Gfunction related to reference point

The machine tool coordinate system is created through returning to reference point after NC is electrified every

time. The reference point is a fixed point on the machine tool, and its position is determined by the installation

position of stopper switch of every axis and the home position of the servo motor of every axis. When this

machine tool returns to the reference point, the coordinates of the reference point in the machine tool

coordinate system is X0, Y0, Z0.

2.2.1. Auto return to reference point (G28)

Function:

This instruction makes the axis return to reference point of the machine tool through the center point specified

by IP at the feeding speed of quick positioning.

Format:

Loading...

Loading...