ADTECH9 Series CNC Programming Manual

Generally, this instruction is used to move the workpiece out of the processing area when the entire processing

program ends, so as to unload processed parts and load the parts to be processed.

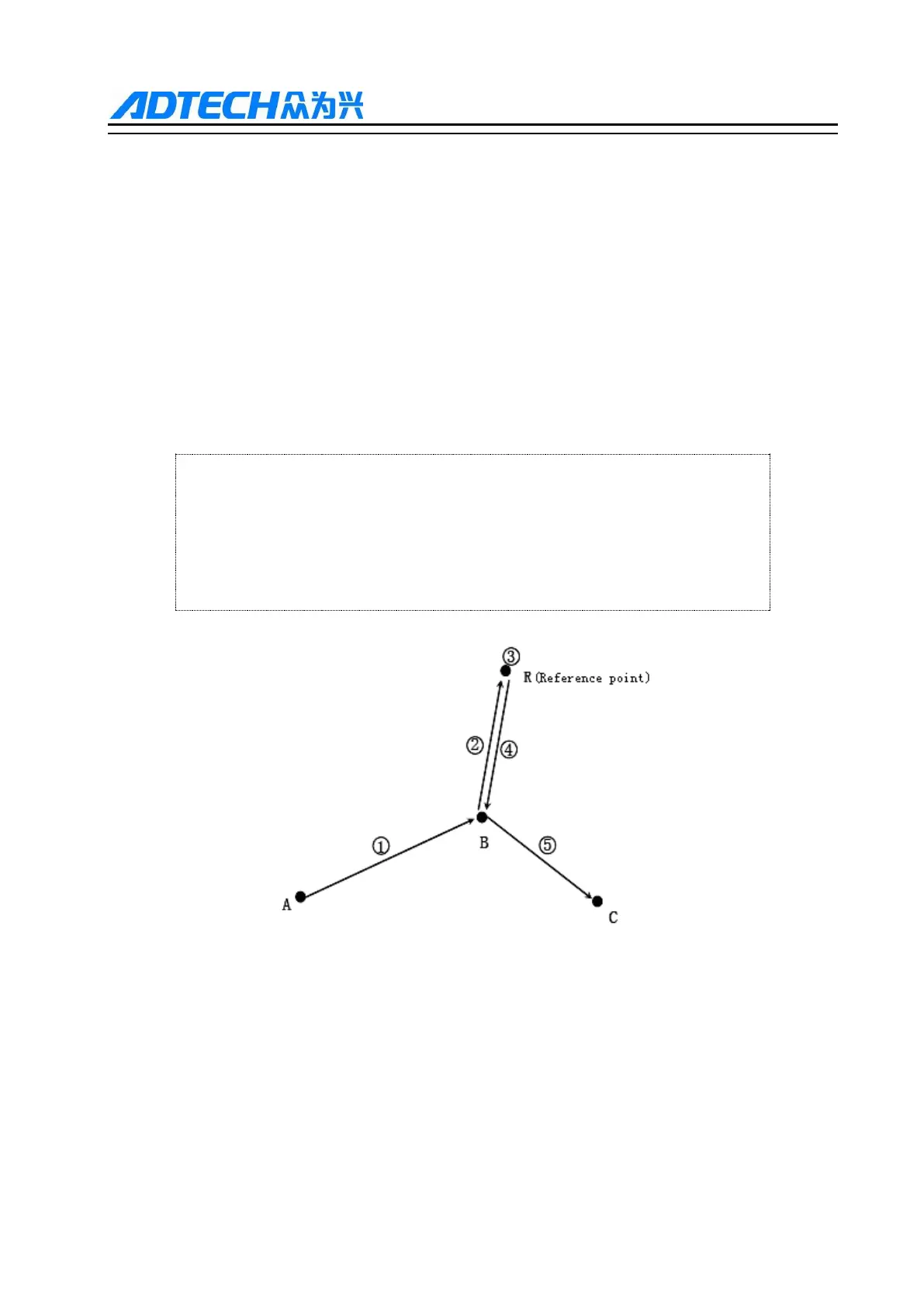

When execute G28 instruction before returning to reference point manually, the motion of every started from

center point is same as returning to reference point manually, and the motion direction started from the center

point is positive.

The coordinates in G28 instruction is saved as center point by NC; on another hand, if an axis isn’t contained

in G28 instruction, the coordinates of the center pointed saved by NC will use the value G28 instruction

specified previously.

Example:

N0010 X20.0 Y54.0;

N0020 G28 X-40.0 Y-25.0; coordinates of center point (-40.0,-25.0)

N0030 G28 Z31.0; coordinates of center point (-40.0,-25.0,31.0

Diagram of Automatically Returning to Reference Point

Note:

The coordinates of this center point are mainly used by G29 instruction.

In tool offset mode, tool offset is also valid for G27; for safety reasons, tool offset should be disabled before

executing G28 instruction (radius offset and length offset).

Loading...

Loading...