6-10 Specifications and Reference Information 5700512-C

Advanced Energy

®

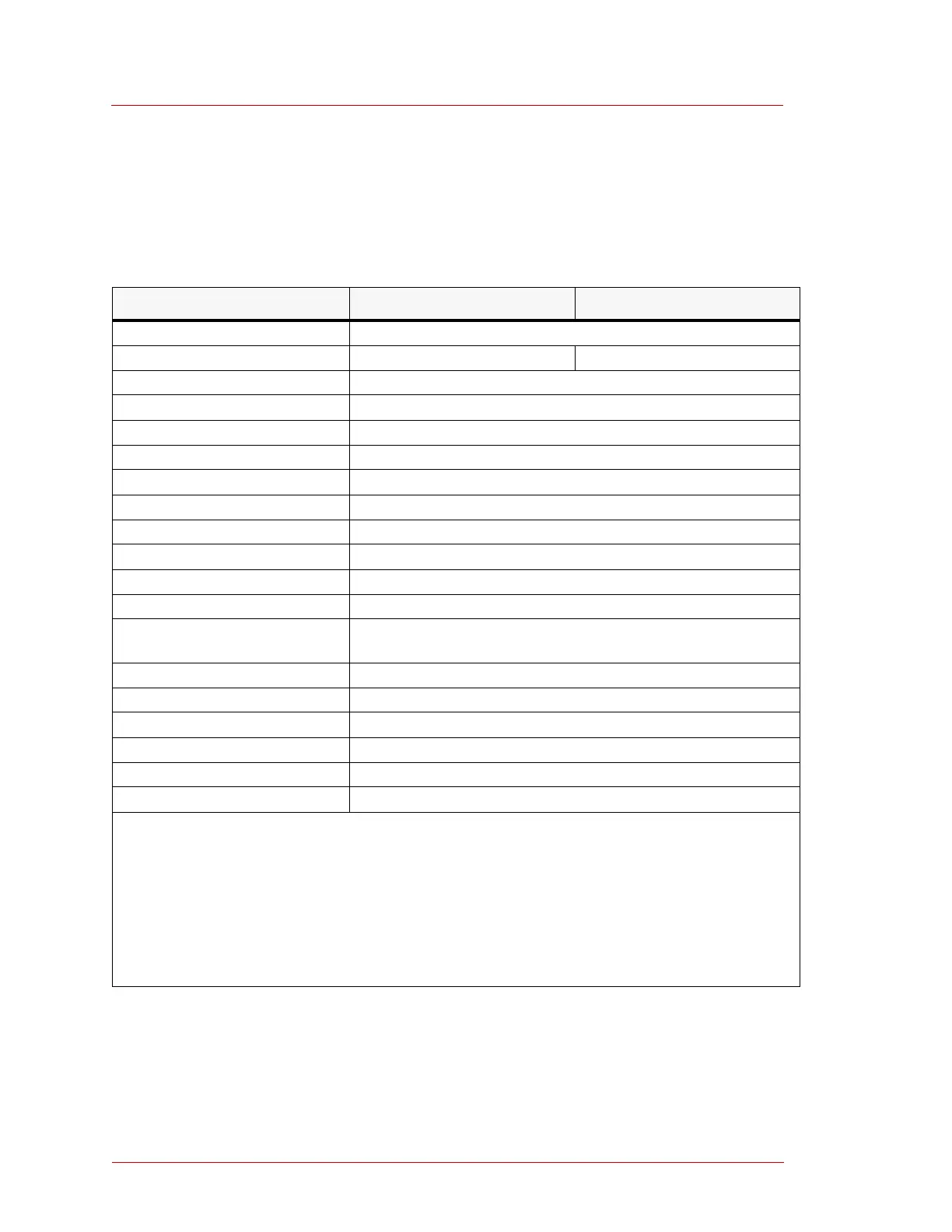

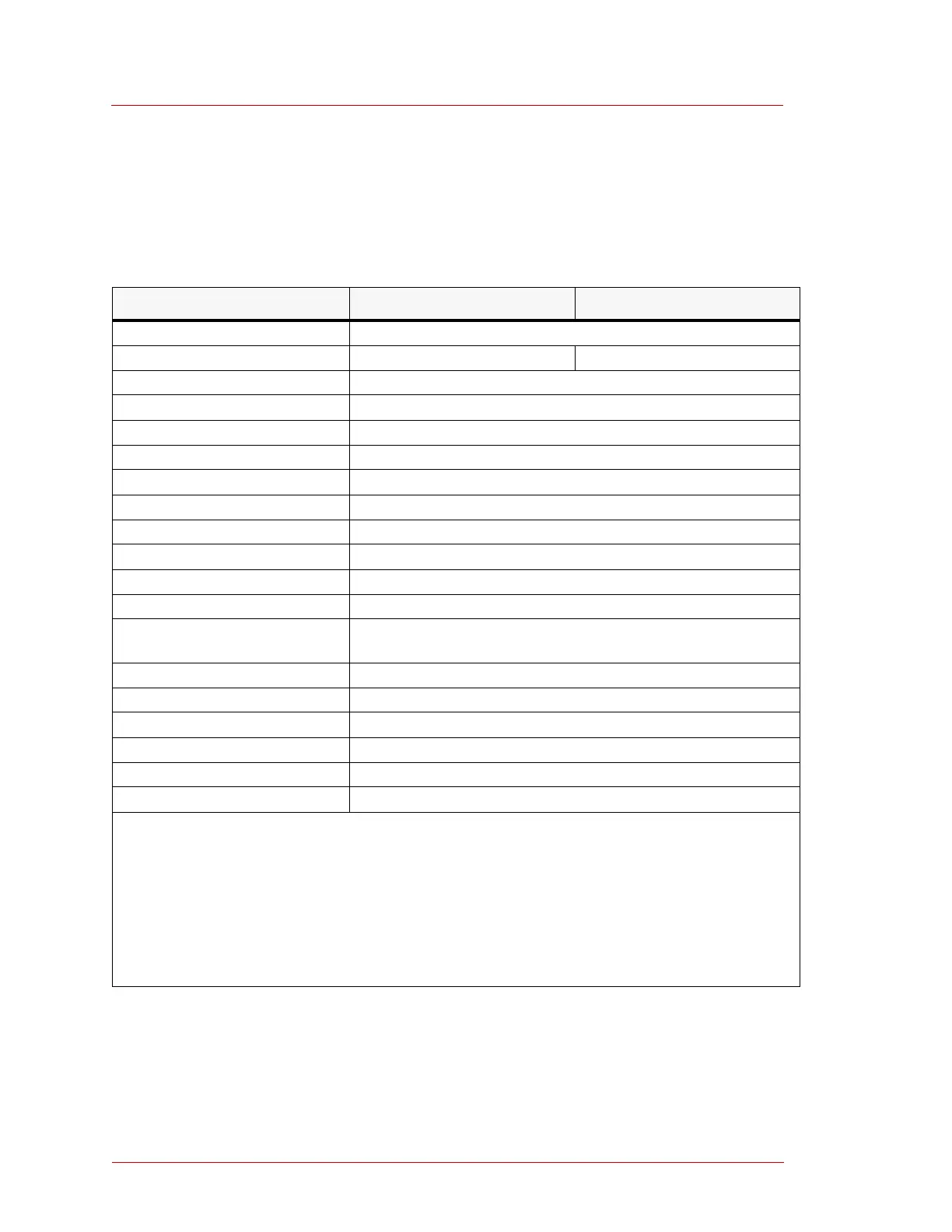

Specifications for Model FC-782 MFCs

The following table lists specifications for the FC-782 MFCs.

Table 6-9. Specifications for FC-782 series MFCs

Specification FC-782 FC-782C

Full-scale range (N

2

equivalent) 35 slm to 150 slm

Valve type Normally open Normally closed

Response time Within 3 s (typical), ±2%

Accuracy

Note 1

Maximum ±2% of full scale

Linearity Maximum ±1% of full scale

Repeatability Maximum at ±0.2% of full scale

External leak rate Maximum 1 x 10

-11

[Pa*m

3

/sec(He)]

Flow rate control range 2% to 100%

Operating pressure range 147 to 275 kPa(D); 21 to 40 psi(D)

Proof pressure

Note 2

981 kPa(G); 142 psi(G)

Operating temperature 5ºC to 45ºC (41ºF to 113ºF)

Flow rate setting and output signal 0 VDC to 5.0 VDC

Supply power Minimum +15 VDC ±2% 25 mA

Minimum -15 VDC ±2% 220 mA

Power consumption Maximum 3.7 W

Gas-wetted surface material

Note 3

SUS316, SUS316L, PTFE, KM-45

Standard fitting

Note 4

1/4″ VCR, 3/8″ VCR, 1/4″ UJR, 3/8″ UJR

Mounting position Any direction

Weight 2.8 kg (6.2 lb)

Options Current output (0 mA to 2.5 mA), error detection function

Note 1—Accuracy ensures that the calibration gas equivalent flow is ±1% of full scale when 22 ± 3ºC in

temperature is obtained for the primary reference in the specified operating pressure range. If the service gas

and calibration gas are the same, the measured gas is ensured to be ±1% of full scale in the specified operat-

ing pressure range as to our primary reference.

Note 2—The proof pressure specification does not ensure operation or accuracy.

Note 3—Use of PTFE, Viton, or Chloroprene rubber may be required depending on the intended flow rate

range.

Note 4—3/8″ VCR or 3/8″ UJR fitting is required if 100 slm or more is derived from full-scale range N

2

equivalent.

Loading...

Loading...