BYB User Manual Page 27 of 55 PN: 90020 Version: 1.4

Tips and Troubleshooting Lock Linkages

Install the spring from the hardware box onto the eyebolt and washer welded on the long 3/8 Round Rod.

With the lock opposite the T-bar installed and the T-bar pointed up and down (12’o clock) on both the front

and back Crossmembers, adjust the top hiem in figure 5.5 so the hole in the hiem and T-bar line up. Install

the 3/8-24 SCHC and nut, placing the split washer BETWEEN the T-bar and Hiem joint.

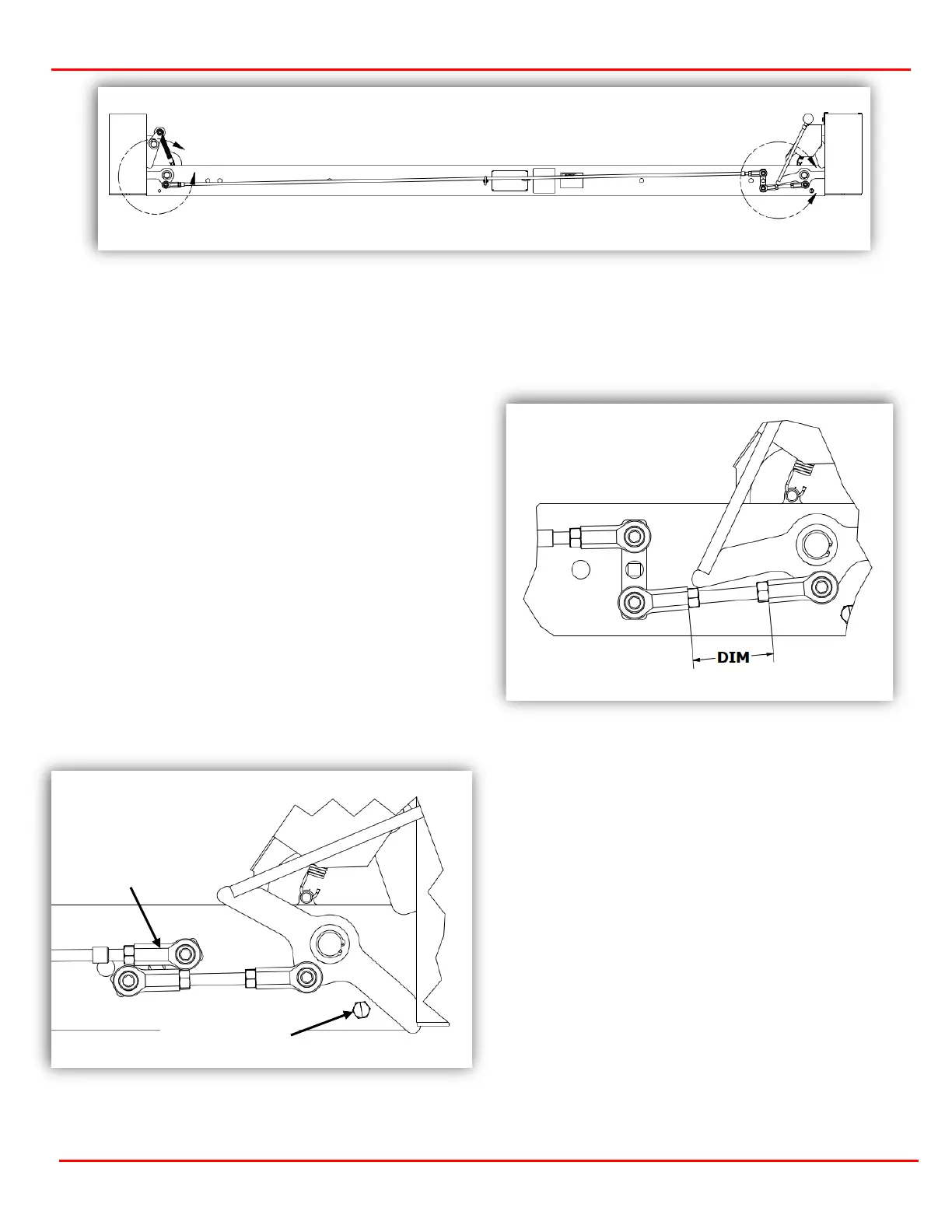

Once installed, the lock linkages will need

adjusted. Start with the dimensions shown below

for the all-thread pieces on both Crossmembers.

These dimensions are just a starting point.

NOTE: the dimensions shown are taken from the

end of the hiem to the end of the opposite hiem.

CL/XT/BT: DIM = 2.4375 (2-7/16)

WF/WB/BB: DIM = 10.5 (10-1/2)

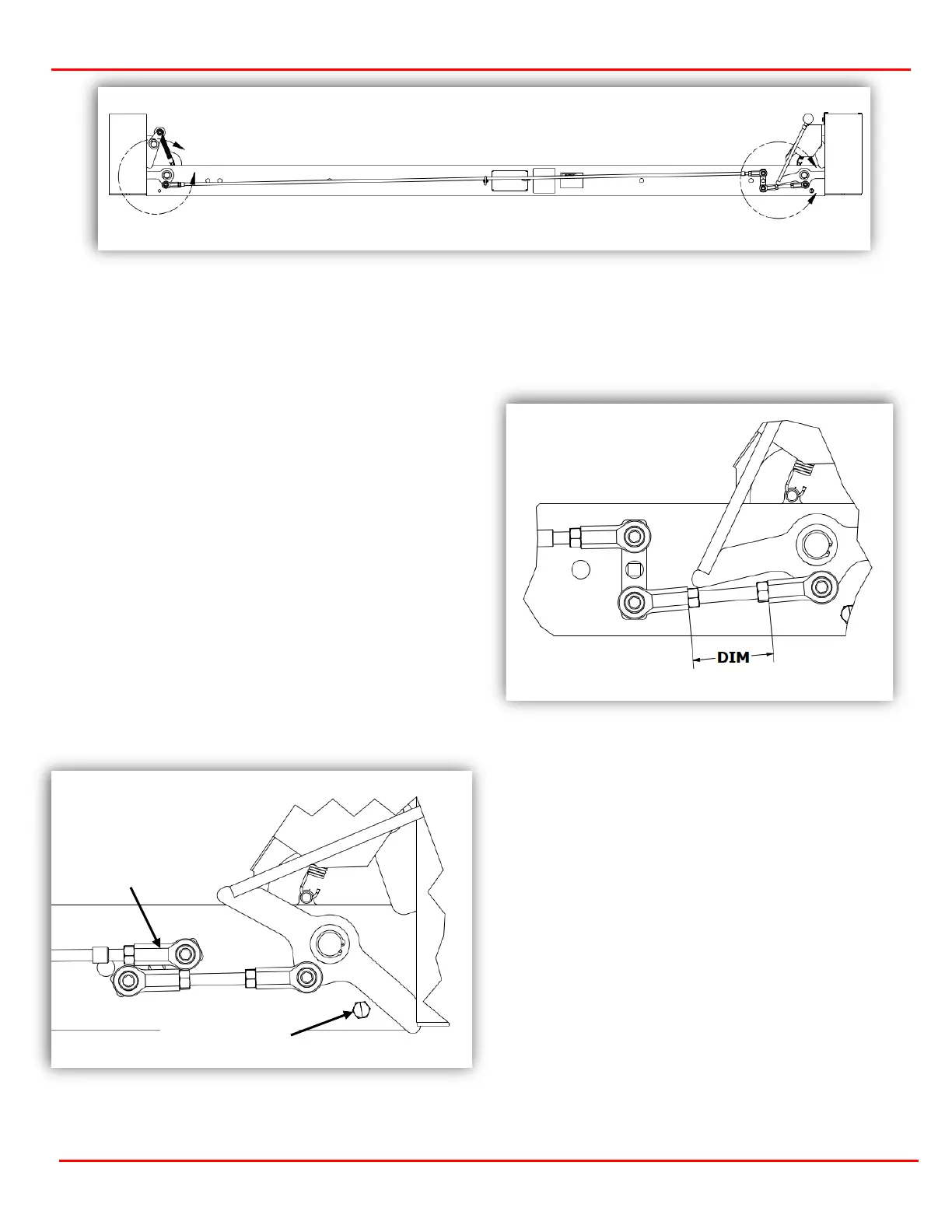

TIP 1: The T-bar needs to fully collapse to produce

the most amount of travel. Ideally the T-bar should

be almost horizonal when the Lock Handle is pulled

to release the Locks (see figure 5.6).

Tip 2: To get MORE lock travel, the All-thread needs

to be LENGTHENED. The longer the All-thread, the

more travel. CAUTION: if the All-thread assembly is

adjusted is too long, it may bend the T-bar. Always

make minor adjustments and test.

Tip 3: When properly adjusted, all locks will release,

and the Lock Handle will not touch the Stop Bolt

(see figure 5.6).

Tip 4: If the Hiem joints do not fully rotate, make

sure the split washer is installed between the hiem

and mating surface NOT on next to the nut.

of Stop Bolt

Loading...

Loading...