BYB User Manual Page 40 of 55 PN: 90020 Version: 1.4

Troubleshooting Guide

This system contains components that have stored electrical and mechanical energy. If the lift is not

operating correctly follow proper lock out/tag out proceedures. If possible place the lift on the locks to

release mechical engery stored in the cables and unplug the power unit and call Advantage Lifts at 763-300-

5730 for further assistance. Repair work must be performed by a qualified person.

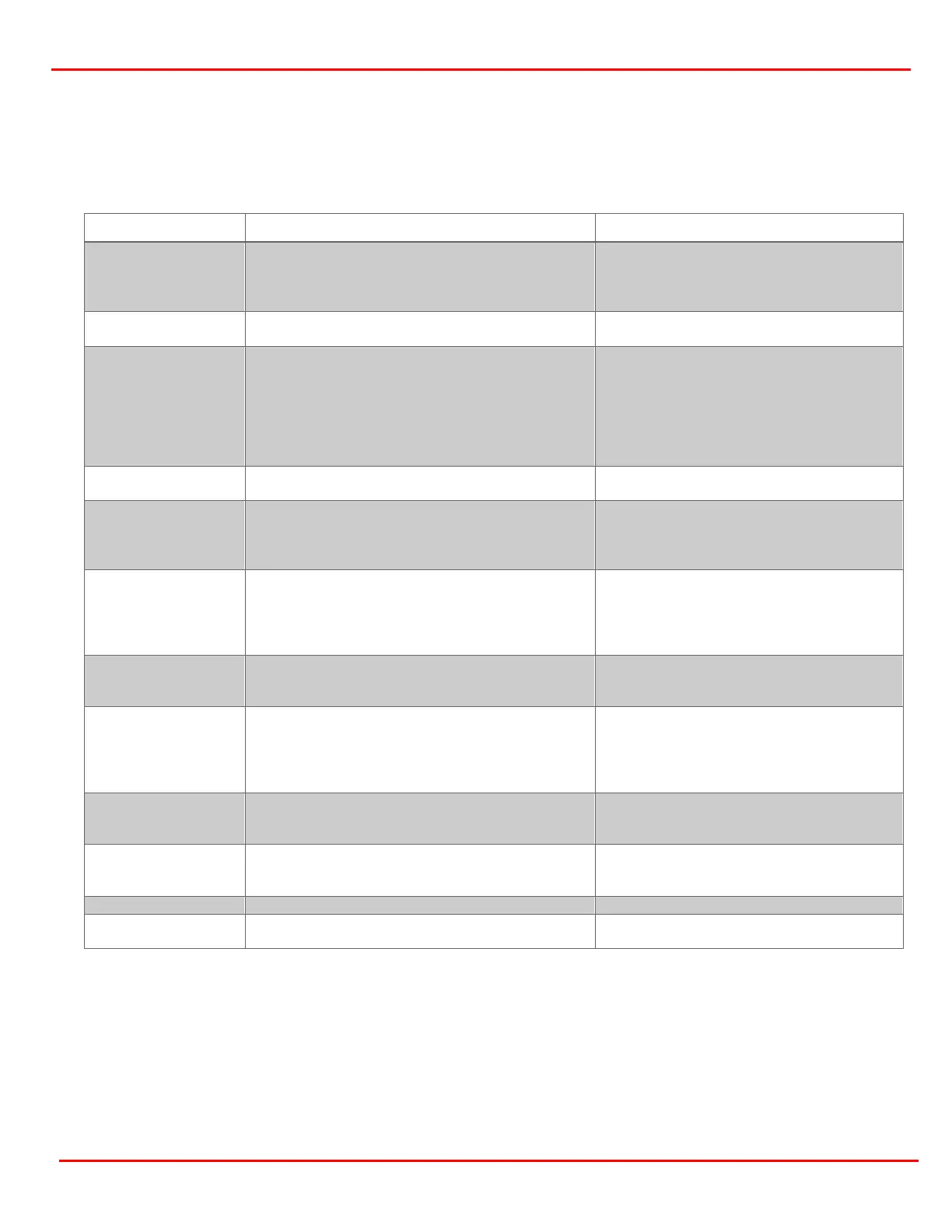

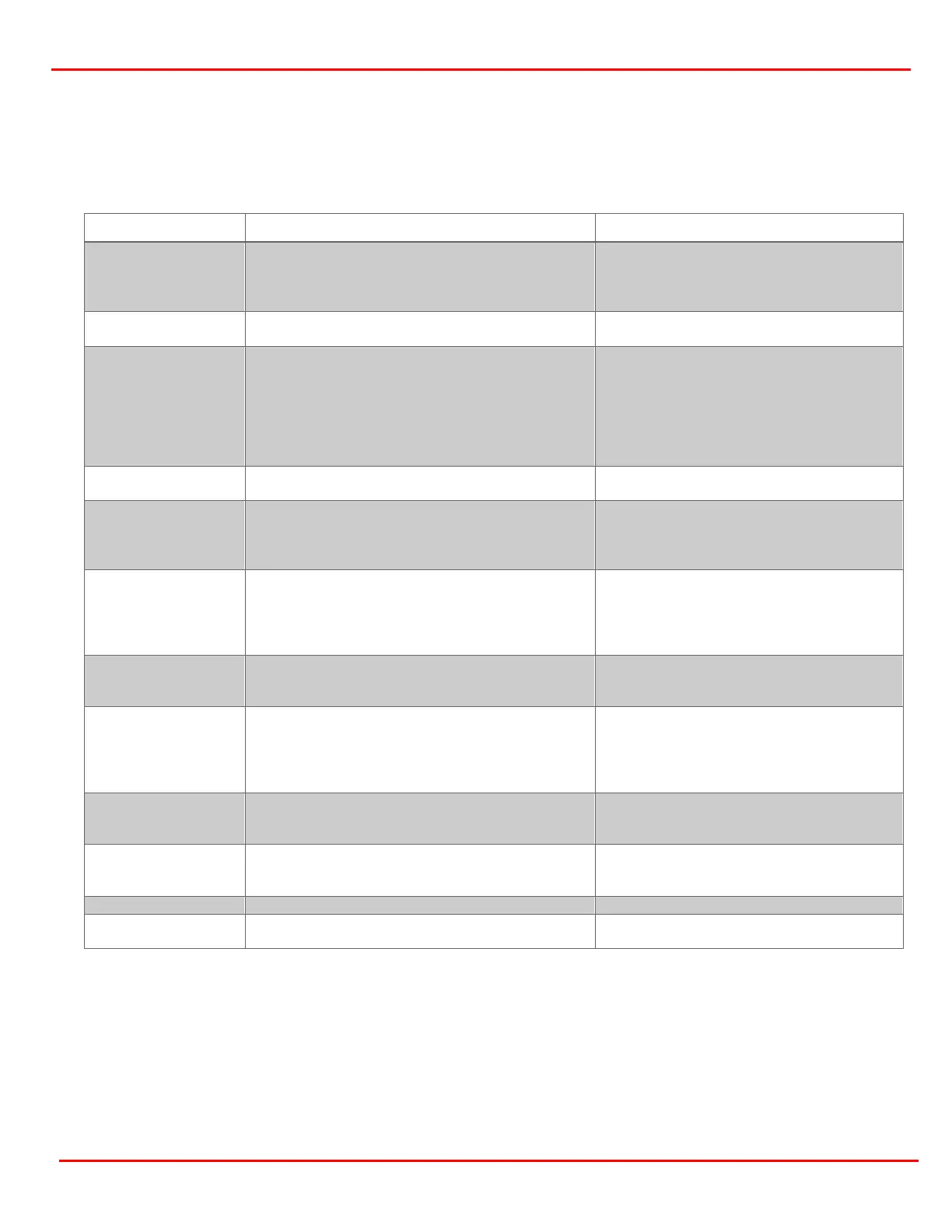

Pump/motor does not

start

• Improper electrical hook-up.

• Blown fuse or breaker tripped.

• Pump binding or stuck.

• Motor thermal overload tripped.

• Review electrical requirements.

• Replace fuse/reset breaker.

• Flush unit/replace pump.

Pump/motor operates

but no pressure

• Wrong rotation of motor (air bubbles in outlet) • Rewire (qualified electrician)

Pump/motor

operate low flow

and/or low

Pressure or does not

hold the system.

• Clogged inlet strainer (cracking noise).

• Relief valve leaking.

• Dirt on seat.

• Release valve leaking or out of adjustment

• O-Ring missing or cut.

• Relief valve setting too low

• Defect in blowhole in motor end head internally.

• Clean strainer in solvent

• Tighten relief valve

• Flush seat

• Readjust stem setting.

• Replace o-ring.

• Readjust relief valve.

Failure to lower

• Release valve stem sticking.

• Lift out of adjustment.

• Replace or readjust stem/cartridge.

• Readjust lift

Air in oil

• Loose inlet connection.

• Low fluid level.

• Bad seals in pump.

• Siphon check does not seat.

• Add fluid.

• Replace seals.

Oil blows out the

breather/filter port

• Oil reservoir was overfilled.

• Vehicle has been lowered too fast.

• Seal damage in cylinder.

• Relieve pressure and reduce oil level.

• Lower the lift slowly while under load.

• Restrict lowering with manually controlled

release valve

Motor functions, but

lift will not rise

• Debris may be under check valve.

• Oil levels are too low.

• Simultaneously push the handle down and

push the rise button; hold for 10-15 seconds

• Check the reservoir and fill as needed.

Runways will not

raise or lower, once

raised

• Lift over capcity

• Low oil levels

• Remove load, try lifting again.

• Add fluid.

• Check hoses for pinches or leaks.

• Remove air from the hydraulic system.

• Replace hydraulic oil if contaminated

runways is lower than

Safety lock on the lower corner is not engaged.

• Raise the lift, and make sure are all locks

are engaged on the same safety lock height.

Adjust the hiem joint linkages.

Lift is stuck up in air

past top lock.

• The cylinder has maxed out causing the check

valve to lock up.

• Hold in the power unit button for a few

seconds and then slowly push down on the

• Check functional parts for wear.

• Lubricate bushings and sheaves.

Lift chatters when in

operation

• Legs are binding in the sleeves.

• Wax the legs to allow the sliders to glide

easily.

Lockout instructions: If the lift becomes inoperable in the raised position, lower the lift as to rest it on the

nearest lock position and call Advantage Lifts at 763-300-5730 for further assistance. In the event of a

mechanical issue that creates a safety concern disconnect the lifts power source and place a tag on the

power unit stating "Do Not Use" until the issue is resolved.

Advantage Lifts offers technical support with all of our products. Call 763-300-5730 with any questions on

the operation and maintenance of your lift. Our knowledgeable staff will be glad to help you.

Loading...

Loading...